Line drawing method and line drawing tool for on-site assembly

A technology for on-site assembly and line-drawing tools, applied in manufacturing tools, workshop equipment, etc., can solve problems such as low work efficiency and many scrapped parts, and achieve the effects of reducing scrap rate, easy operation, and improving fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

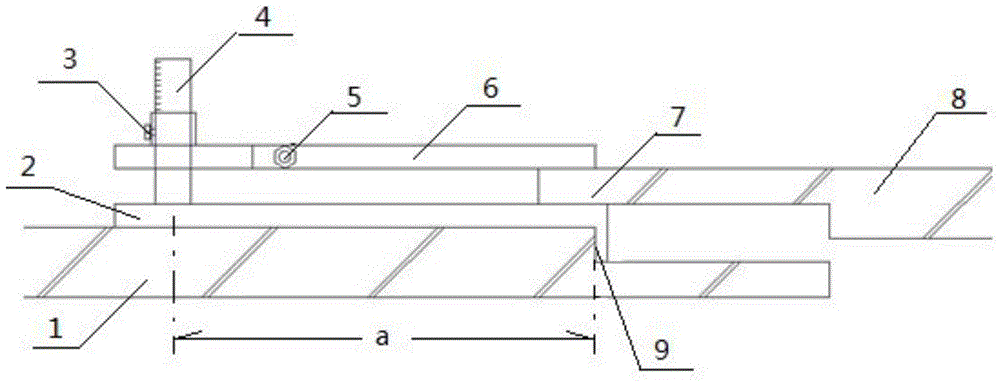

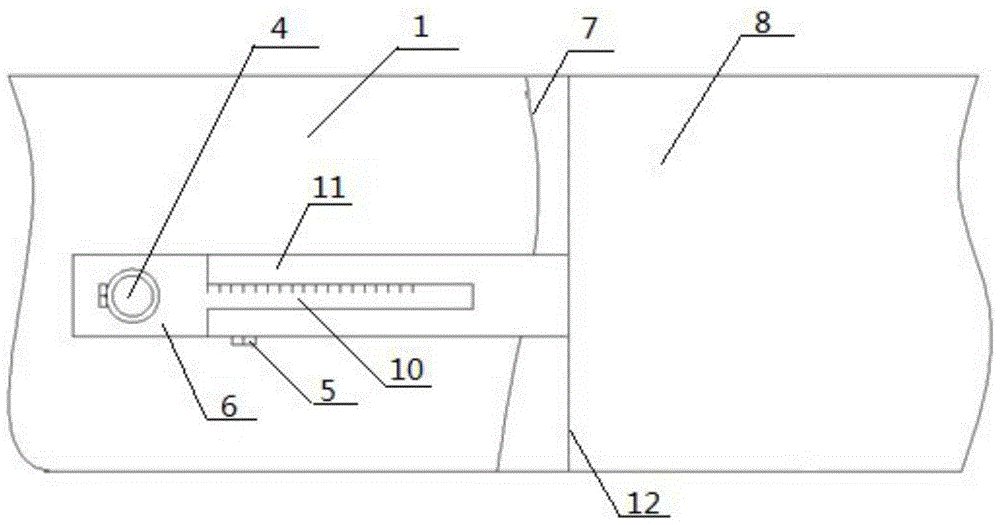

[0017] The present invention is described below in conjunction with accompanying drawing:

[0018] A line-drawing method for field assembly comprising the following steps:

[0019] A. Cutting and rough machining: Preliminary cutting of the assembly 8 and rough machining;

[0020] B. Positioning of the contact surface 9: install and fix the mounting part 1, and determine the position of the curved surface on the mounting part 1 that is in contact with the assembly part 8 as the contact surface 9;

[0021] C. Semi-fixing the assembly part 8: fix the positioning end of the assembly part 8 in step A, and lap the grinding end 7 on the surface of the mounting part 1;

[0022] D. Draw a line on the mounting part 1: Use one side of the square to clip on the contact surface 9 of the mounting part 1, and the other side of the square to overlap the mounting part 1, and the mounting part 1 with a fixed distance a from the square Draw a point on the top, and the inner surface of the shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com