Clamping device of linkage type pipe fitting

A clamping device and linkage technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of bloated mechanism, increase energy cost, increase the weight of manipulator arms, etc., and achieve the effect of energy saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

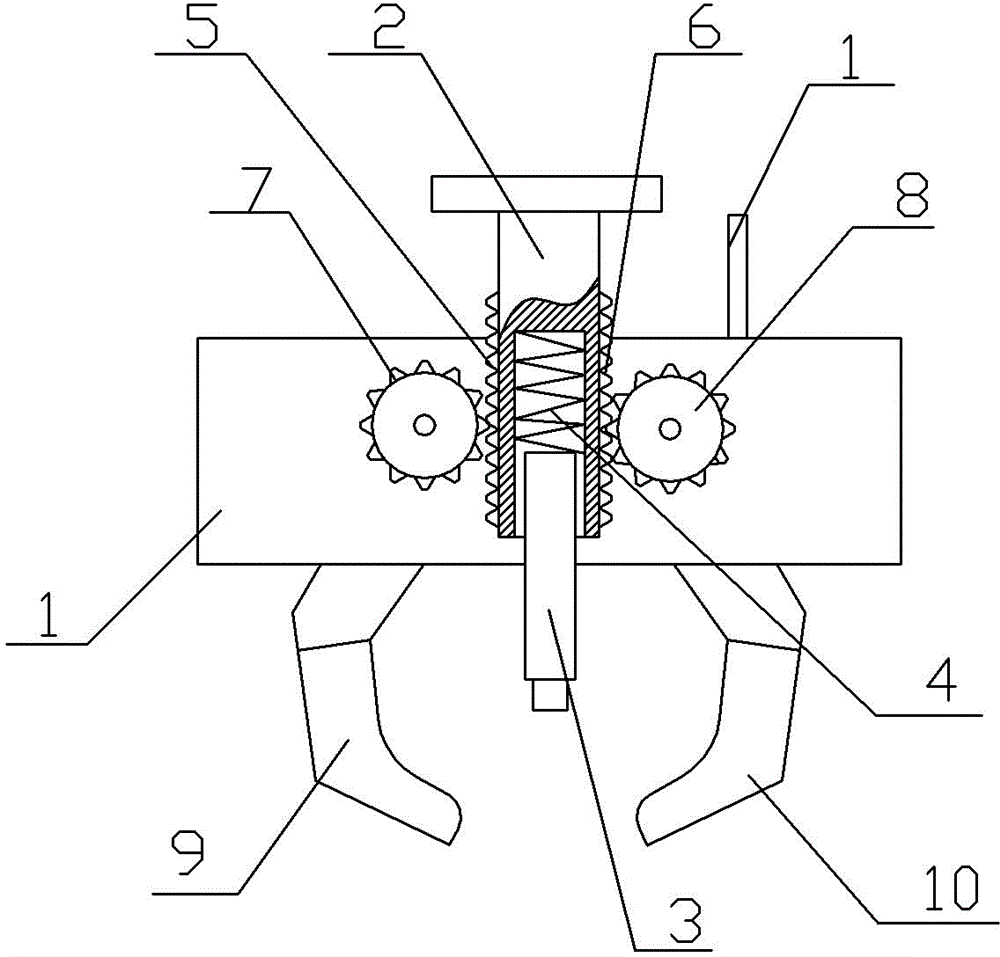

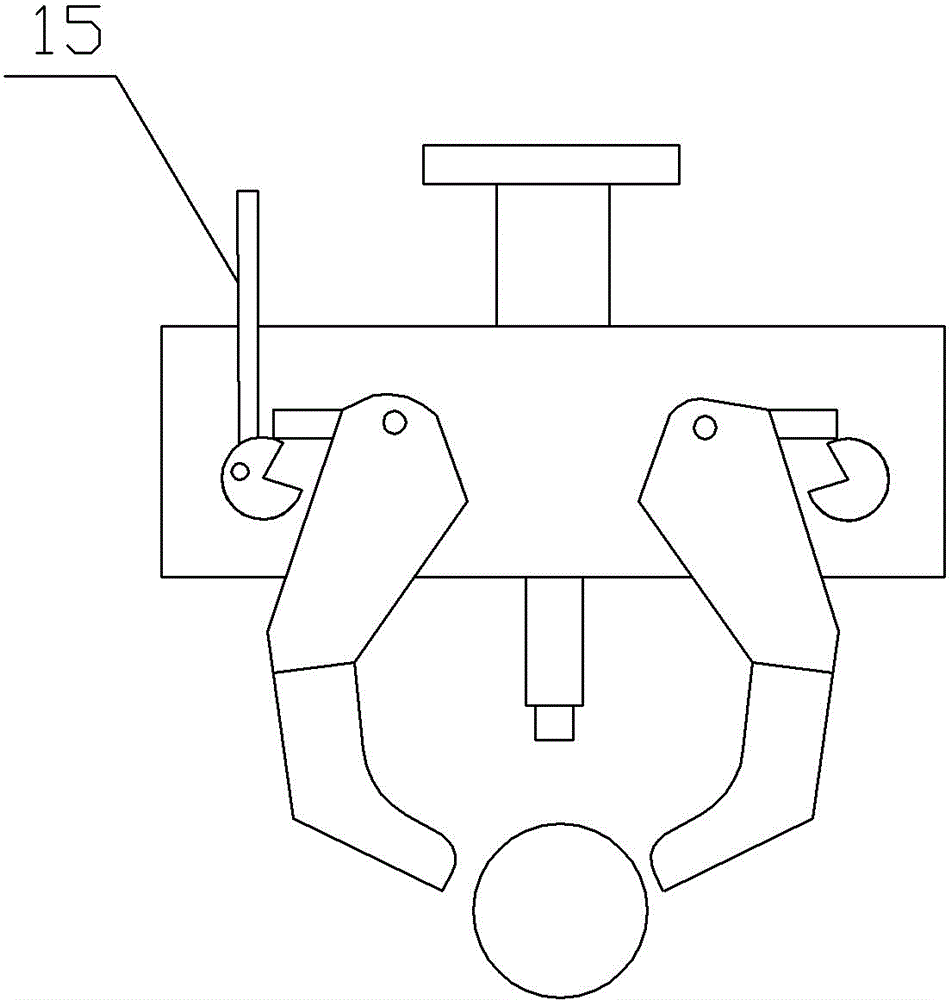

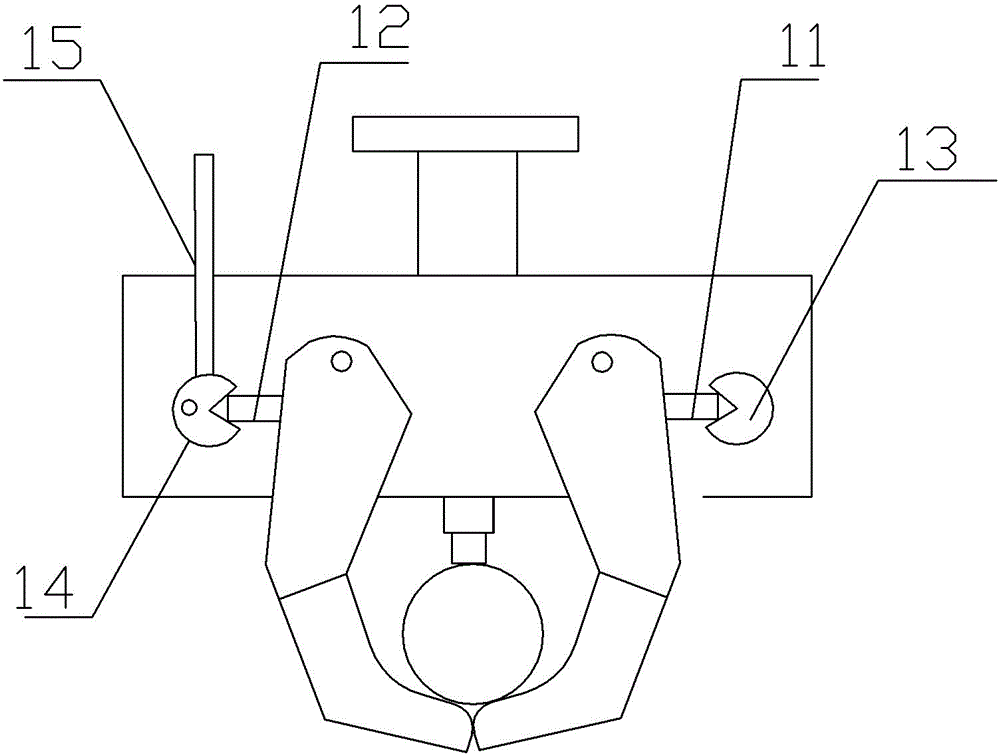

[0014] The reference signs in the drawings of the description include: workbench 1, linkage rod 2, pressure rod 3, buffer spring 4, left rack 5, right rack 6, left gear 7, right gear 8, left jaw 9, right Jaw 10, left clamping block 11, right clamping block 12, left clamping wheel 13, right clamping wheel 14, insertion rod 15.

[0015] The embodiment is basically as attached figure 1 , figure 2 and image 3 Shown: Linkage pipe clamping device, including a worktable connected with the mechanical arm, and the worktable can move with the movement of the mechanical arm. There is a cavity in the workbench, the linkage rod runs through the linkage rod from top to bottom, the upper part of the linkage rod is welded with a cover plate, the linkage rod has an inner cavity, and there is a pressure rod in the inner cavity, and the pressure rod and the bottom of the inner cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com