A mobile nozzle type circular tube inkjet coding line

A technology of moving nozzles and circular tubes, which is applied in the direction of power transmission devices, printing, transfer materials, etc., can solve the problems of easy changes in inkjet codes, difficulty in turning, and unqualified straightness of inkjet codes, so as to prevent roundness Tube rotation, well-proportioned fonts, and good clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

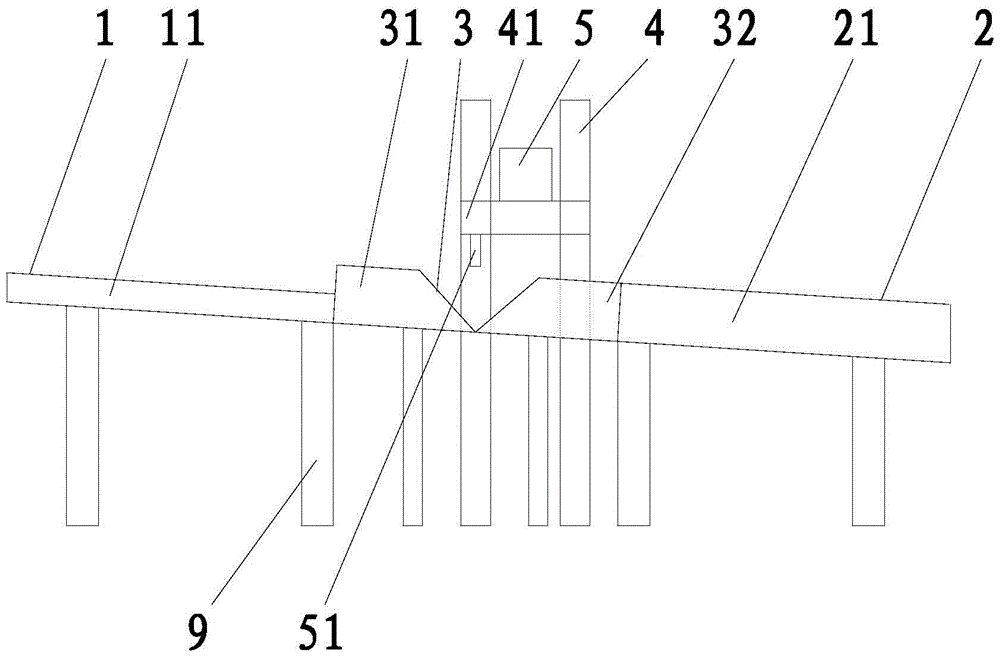

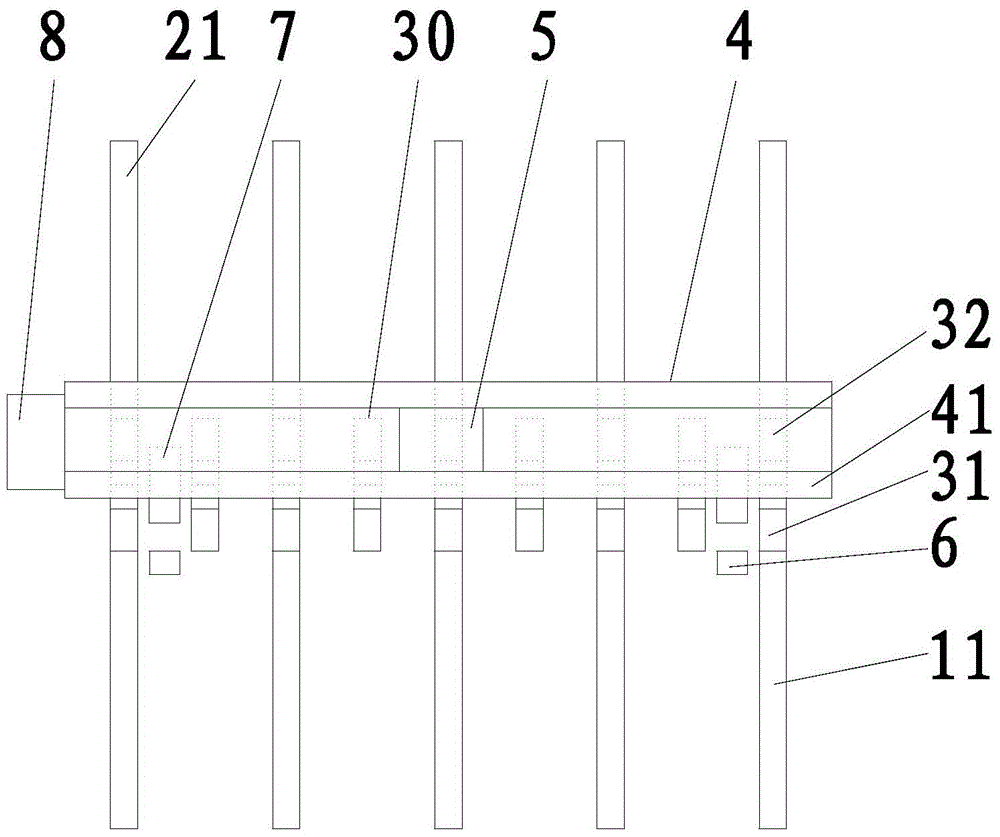

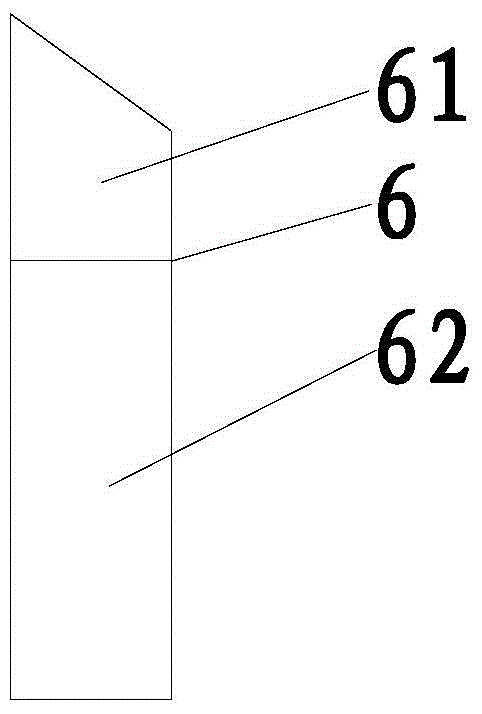

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , a mobile nozzle type circular tube coding line of the present invention, comprising a feeding platform 1, a discharging platform 2, a V-groove platform 3, a gantry frame 4, and a coding machine 5, and the feeding platform 1 is composed of several horizontally arranged The first support bar 11 is formed, the discharge platform 2 is made up of some second support bars 21 arranged horizontally, and the V-groove platform 3 is made up of several V-groove groups 30 arranged horizontally, and the V-groove group 30 is composed of a left V-groove block 31 Composed with the right V-groove block 32, the left V-groove block 31 and the right V-groove block 32 are in the shape of a right-angled trapezoid, the hypotenuses of the left V-groove block 31 and the right V-groove block 32 are opposite, and part of the left V-groove block 31 is connected to the first support The rods 11 are connected, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com