Gloss paint overprinting method of flexo printing machine

A flexographic printing machine and varnish technology, applied in printing, printing devices, etc., can solve the problems of complex equipment and high overprinting costs, and achieve the effects of reducing equipment costs, improving efficiency and automation, and shortening engineering and installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

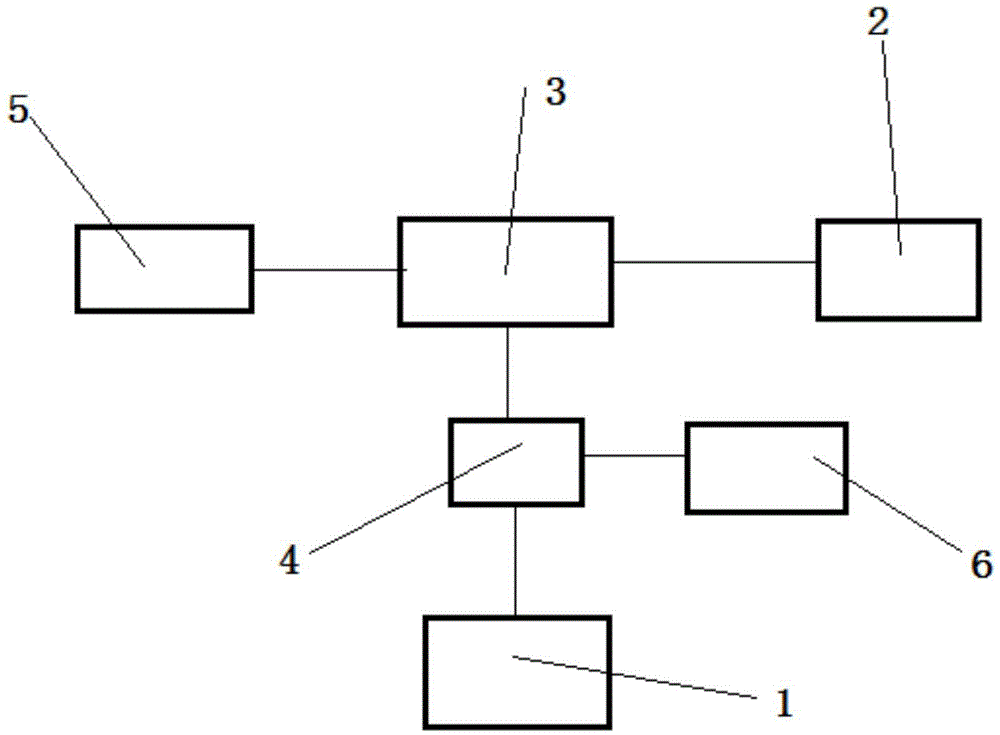

[0024] A varnish overprinting method for a flexographic printing machine, using a varnish overprinting system, such as figure 1 As shown, the structure of the varnish overprinting system is: including the plate roller feeding driver 3, the plate roller feeding driver 3 is 2094-BM03-M, the plate roller feeding driver 3 is provided with a color mark sensor 5, and the plate roller feeding server The driver 3 is connected to the controller 1 through the switch 4, the plate roller feeding and serving driver 3 is connected with a plate roller motor 2 to provide power for it, and the switch 4 is also connected to a man-machine interface 6, which is convenient for the operator to check the corresponding parameters;

[0025] Specifically, follow the steps below:

[0026] Step 1. Set a periodically appearing color mark block on the printed product. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com