Micro-motion function and hydraulic brake control system of wheeled dozer

A hydraulic braking and control system technology, applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of inability to effectively control the driving force of the tires of the whole machine, heavy parking brake operation, and increased tire wear. Achieve the effect of increasing driving safety, increasing reliability and reducing tire wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

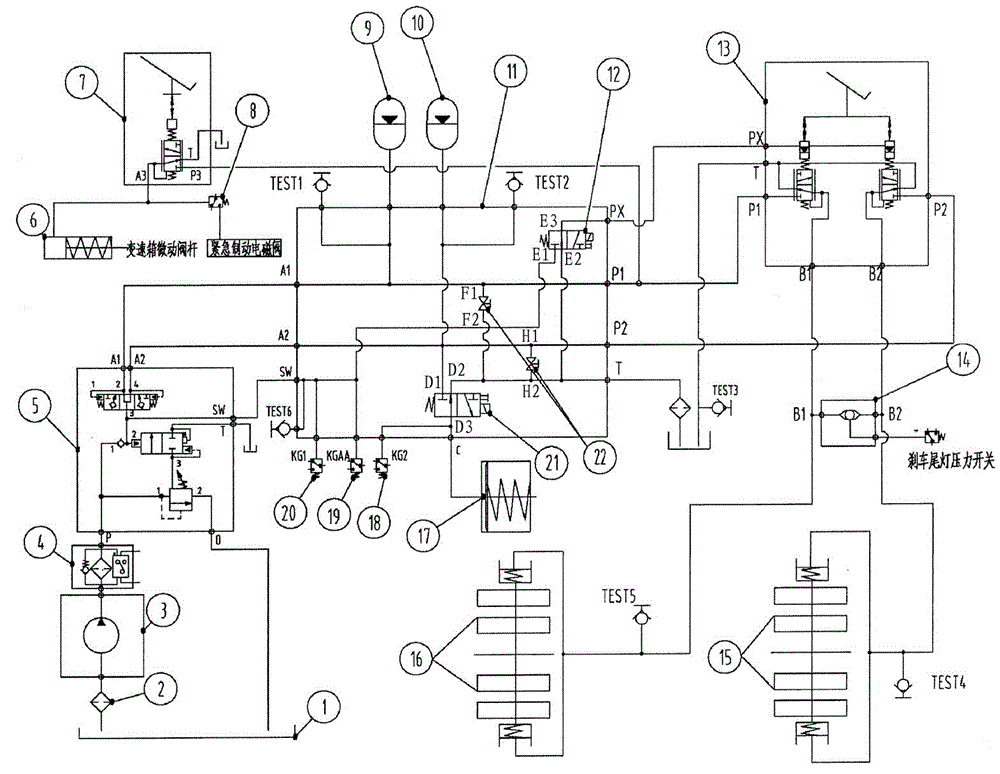

[0025] Such as figure 1As shown, a tire-type bulldozer inching function and hydraulic brake control system of the present invention includes a fuel tank 1, an oil suction filter 2, a gear pump 3, a high pressure filter 4, a liquid filling valve 5, an inching cylinder 6, and a left pedal Valve (micro function pedal valve) 7, pressure switch 8, brake valve group 11, right pedal valve (pilot brake pedal valve) 13, shuttle valve valve group 14, rear axle brake 15, front axle brake 16, parking Vehicle brake 17; the brake valve group 11 is an integrated valve block, including a front axle accumulator 9, a rear axle accumulator 10, an emergency brake solenoid valve 12, a low parking pressure alarm 18, an automatic emergency brake dynamic switch 19, low brake pressure alarm 20, parking solenoid valve 21, first accumulator discharge valve 22, second accumulator dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com