Underframe of a railway gondola car

A vehicle chassis and railway technology, applied in railway car body components, chassis, transportation and packaging, etc., can solve the problems of not being able to adapt to the development requirements of lightweight, difficult to achieve equal strength design, and unable to optimize section size , to achieve the effect of improving the visual effect of the appearance, improving the unloading rate of the cargo, and the reliable connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

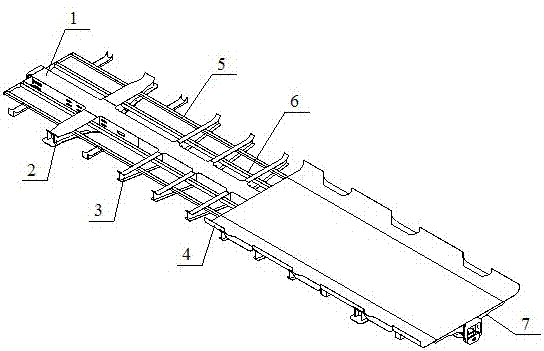

[0021] refer to figure 1 , The present invention includes a center beam composition 1, a corbel composition 2, a beam 3, a floor 4, longitudinal beams 5, 6 and an end beam 7.

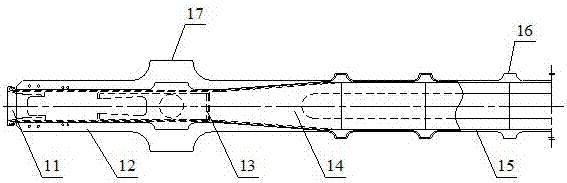

[0022] refer to figure 1 , figure 2 , in the railway gondola underframe of the present invention, the middle beam composition 1 is a steel plate welded box structure, mainly composed of an integrated impact seat 11, a lower cover plate 12, an integrated center plate seat 13, and an upper cover plate 14 , The web assembly is welded by 15 groups. Both ends of the center beam need to be installed with the traction beam part of the coupler buffer device, the inner width of which is the standard 350mm, and the width of the box beam in the middle part is larger, which can increase the bending section modulus of the center beam; further, the web assembly 15 is based on the equal strength The design principle is composed of three sections of steel plates with different thicknesses. The thicker webs at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com