Ship and method for transportation and installation of complete offshore wind turbine

A technology for offshore wind turbines and installation methods, which is applied to barges/flat-bottomed boats, etc., and can solve problems such as high construction risks, long offshore construction periods, and high installation costs of offshore wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

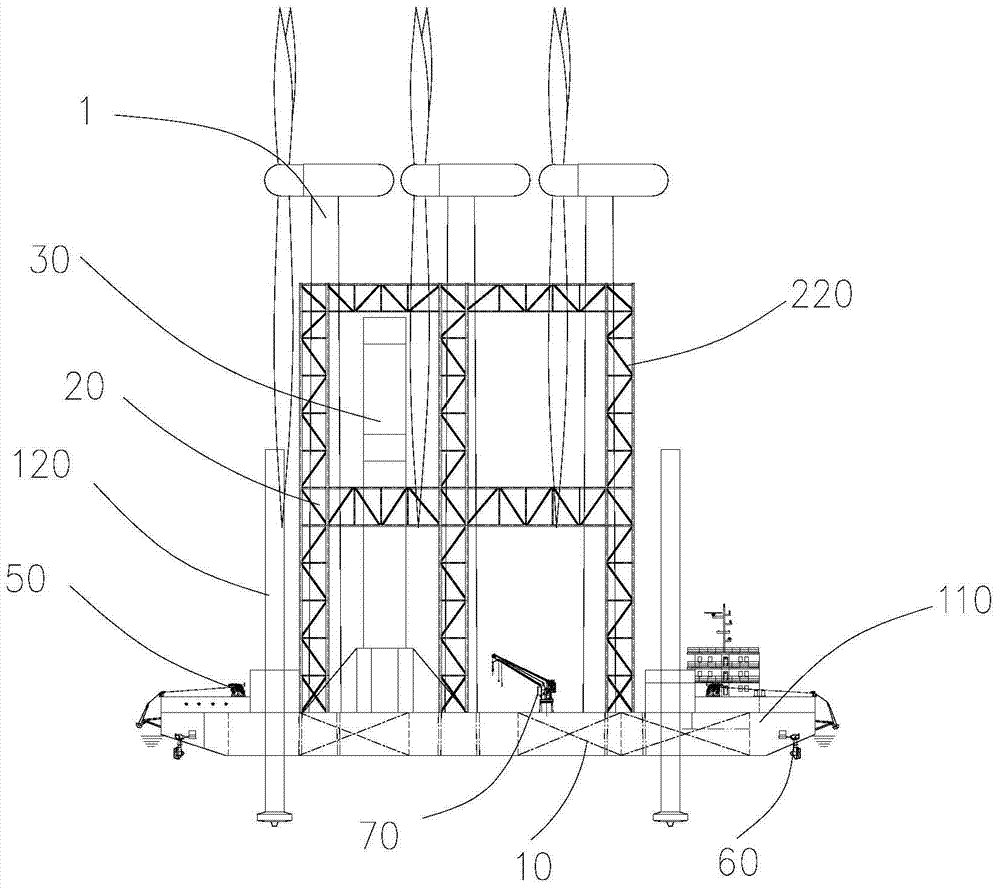

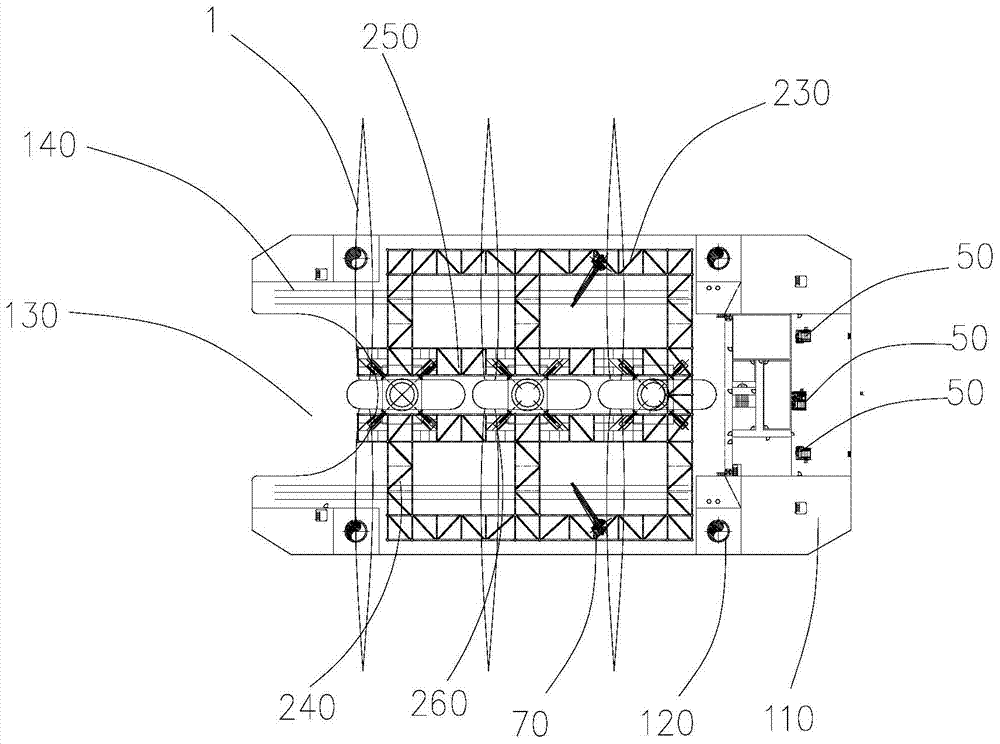

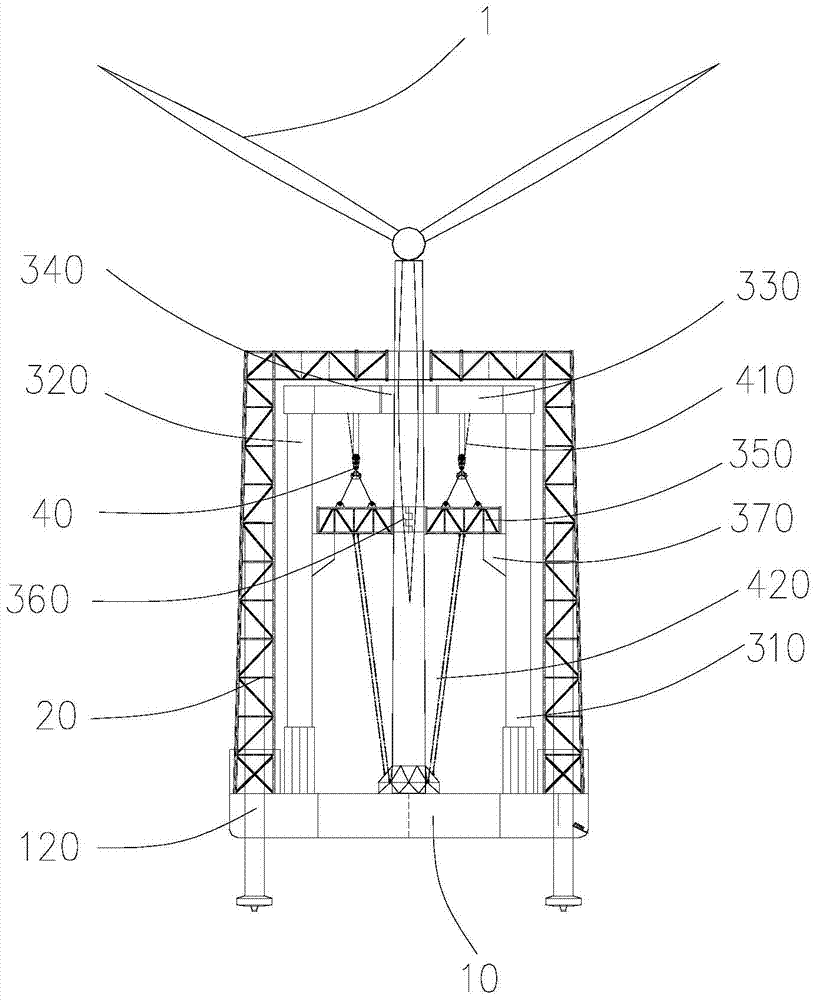

[0034] like Figures 1 to 5 As shown, a special ship for the transportation and installation of offshore wind turbines includes a transport barge 10, a fixed steel frame 20, and a mobile steel frame 30. The transport barge 10 includes a main hull 110 and a cockpit arranged on the main hull 110. and the control system, the main hull 110 is provided with a plurality of self-elevating piles 120, the fixed steel frame 20 is fixedly installed on the main hull 110, and the fixed steel frame 20 is provided with a plurality of first fan hoop mechanisms 210, the moving steel frame is slidably arranged under the fixed steel frame 20, and the moving steel frame includes a first outrigger 310 and a second outrigger 320 oppositely arranged on both sides of the main hull 110, the first outrigger 310 and the second outrigger The upper end of the leg 320 is provided with a spanning support beam 330, the middle part of the support beam 330 is provided with a second fan hoop mechanism 340, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com