Workpiece clamping and conveying device

A clamping device and clamping transmission technology, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of high equipment cost and unstable transmission, and achieve the effects of low cost, avoiding workpiece wear, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

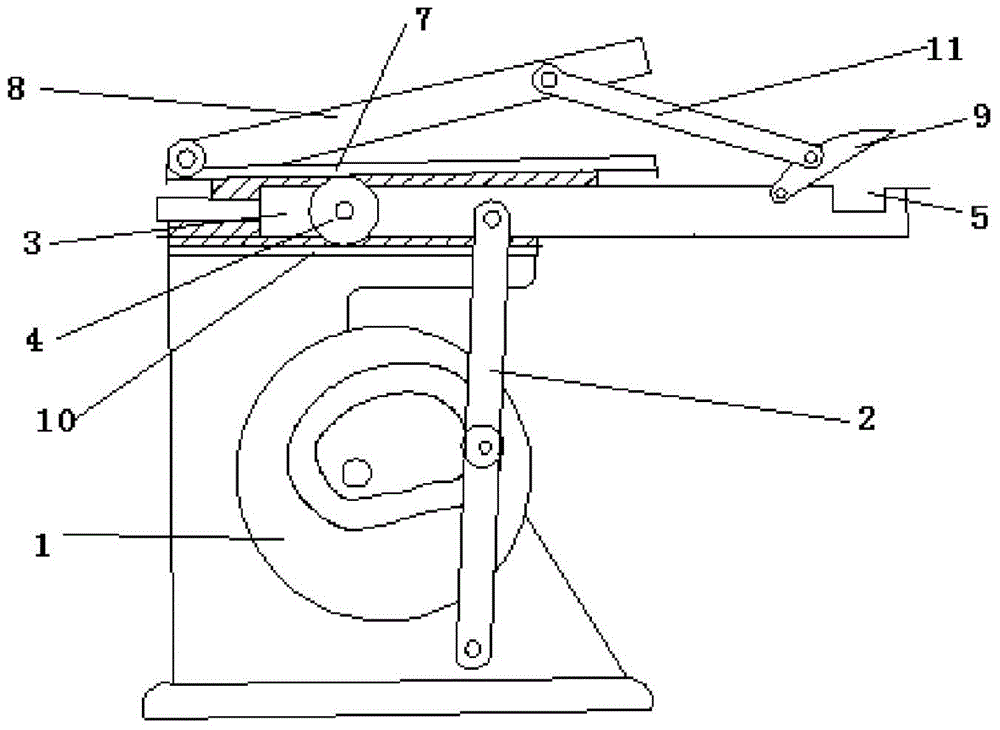

[0012] The reference signs in the description of the drawings are: cam mechanism 1, swing push rod 2, clamping device 3, transmission gear 4, clamping part 5, pressing plate 6, sliding plate 7, transmission pull rod 8, pressing plate 9 , the first rack 10, the linkage arm 11.

[0013] Such as figure 1 As shown, the technical solution provides a clamping and conveying device for workpieces, including a frame, a control device and a conveying device. The conveying device includes a cam mechanism 1 , a swing push rod 2 , and a clamping device 3 . In order to make the device compact in structure, preferably, the cam mechanism 1 is a grooved cam mechanism 1, which makes the swing push rod 2 swing on its end surface, thereby saving swing space. The middle part of the swing push rod 2 is connected to the rolling element of the cam mechanism 1, and the two ends of the swing push rod 2 are respectively on the frame and the clamping device 3, and the two sides of the clamping device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com