Turning device for shaft workpiece with round head end

A U-turn device and workpiece technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high labor cost, high labor intensity, and scrapped shaft processing, and achieve the effect of reducing labor intensity and cost and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

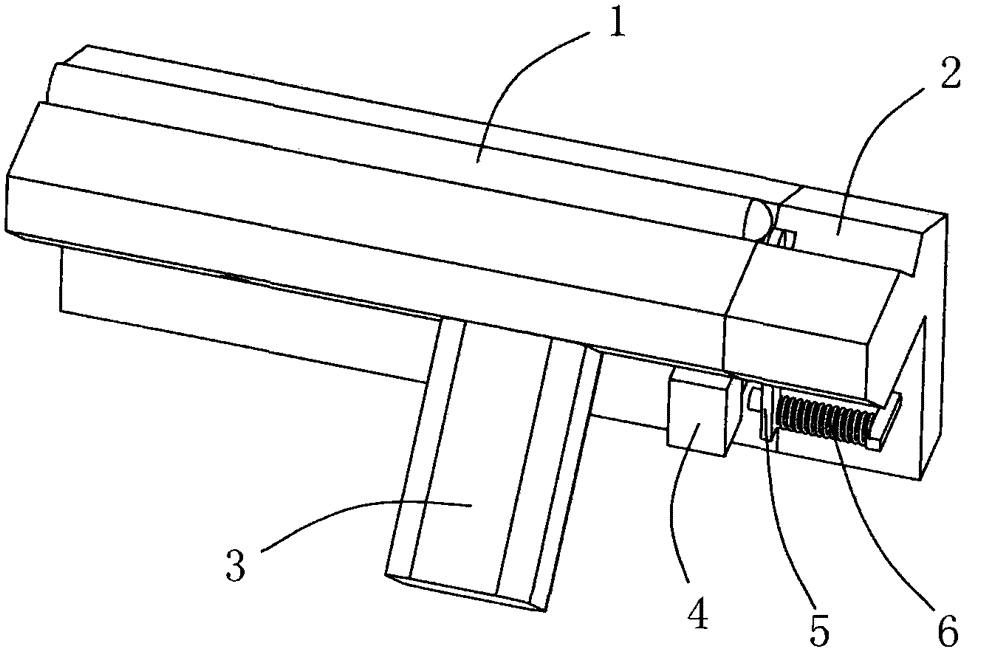

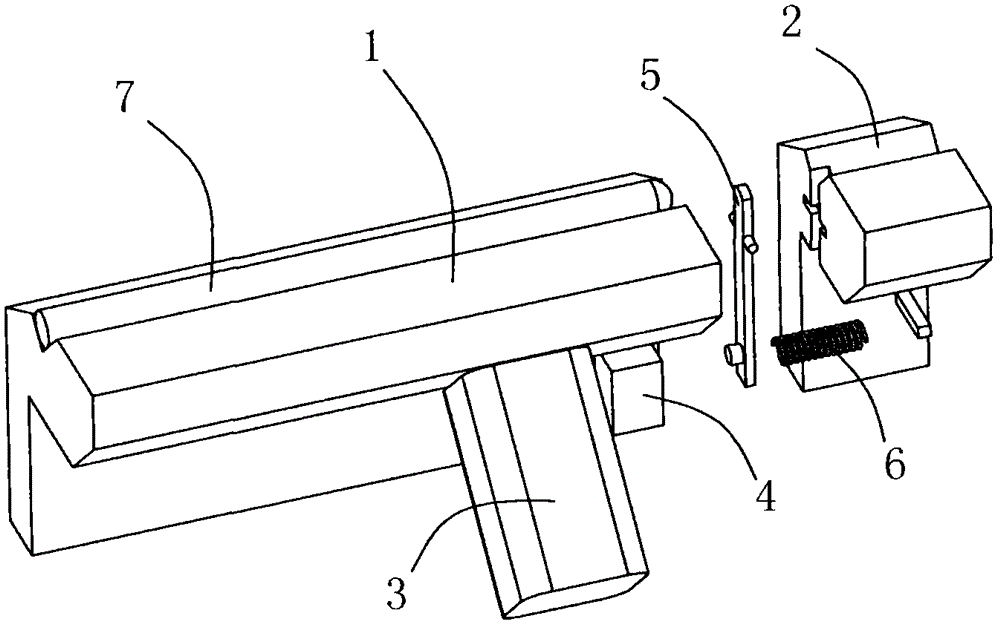

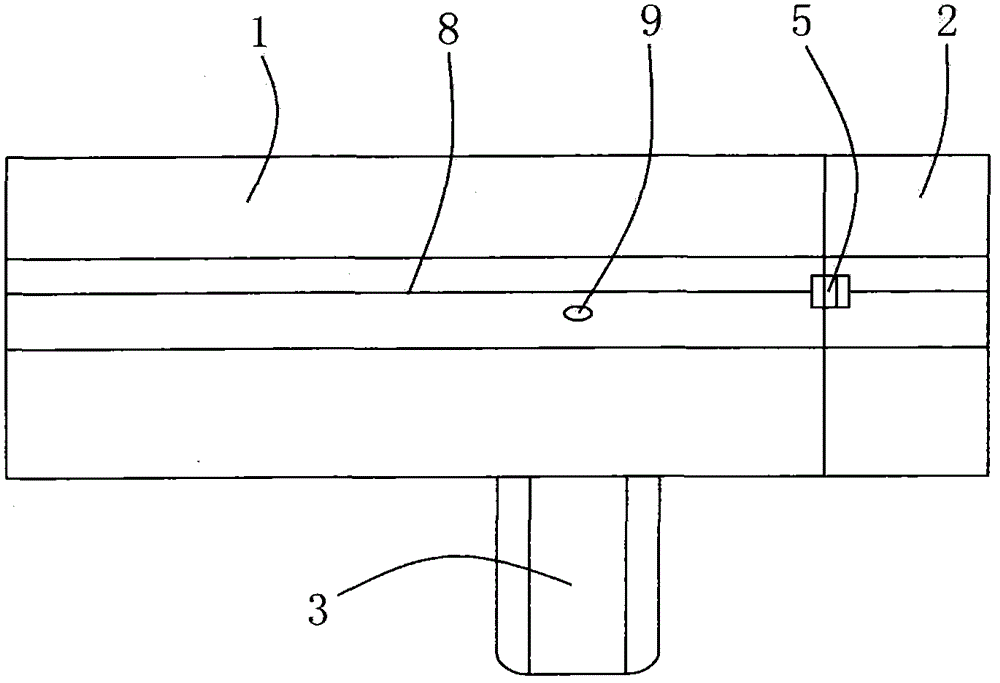

[0016] Examples such as Figure 1 to Figure 5 shown.

[0017] A turning device for workpieces with a round end shaft, including a base 1, an assembly block 2, an electromagnetic push rod 3, a micro switch 4, a shift rod 5 and a first spring 6, and the electromagnetic push rod 3 includes a housing 12, an electromagnetic coil 11. Push rod 10, second spring 13 and end cap 14. The electromagnetic push rod 3 and the micro switch 4 are set on the base 1, the assembly block 2 is set on one end of the base 1, the lever 5 is set between the assembly block 2 and the base 1, the function of the assembly block 2 is to turn the dial The rod 5 can be set on the base 1 up and down, specifically as figure 2 As shown, the end face of the assembly block 2 connected with the base 1 is formed with an accommodating groove for acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com