Pallet fork mechanism matched with electric power engineering construction repair and recovery vehicle

A technology of electric power engineering and emergency vehicles, which is applied to vehicles used for freight, motor vehicles, and goods transport vehicles, etc., which can solve the problems of delaying power emergency repairs, failure to ship, and insufficient free space, etc., to improve emergency repair work Efficiency, convenient and safe fixing, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

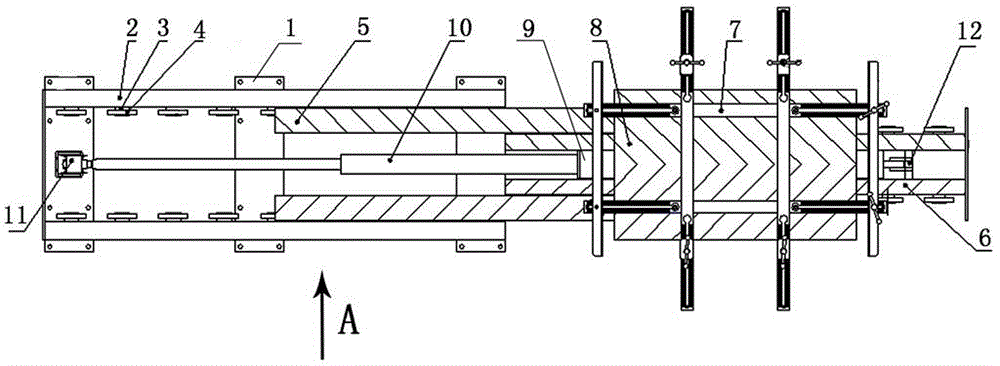

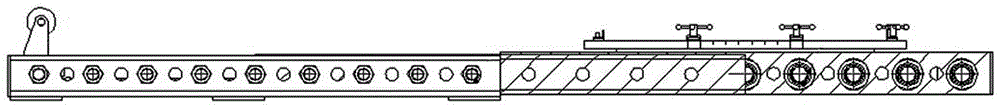

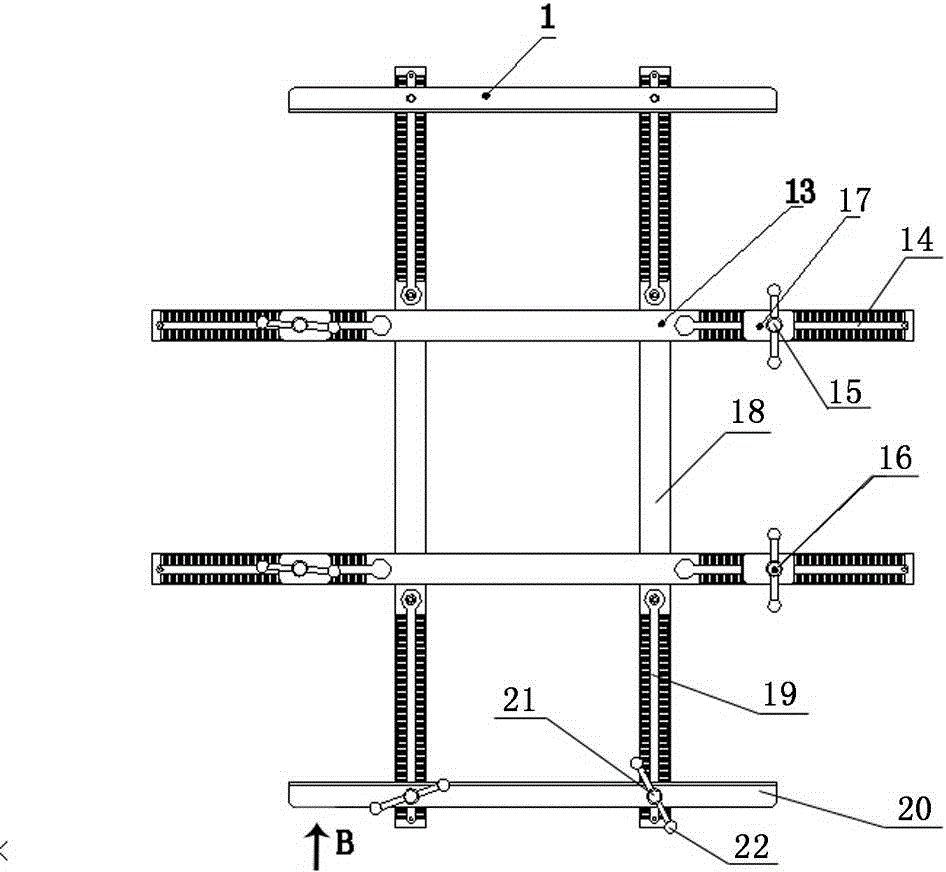

[0013] The invention will be described in detail below in conjunction with the drawings: figure 1 , 2 As shown, the fork mechanism of the present invention, which is used for power engineering emergency repair and rescue vehicles, mainly includes two fork outer slides 2 installed in parallel on the fork fixing plate 1. The fork The inner side of the outer slideway 2 is equipped with multiple bearing roller sleeves 4 that respectively pass through the bearing fixed shaft 3, and the middle slideway 5 of the two forks is next to the inner side of the outer slideway 2 of the fork and is respectively sleeved through the lower slide groove The bearing roller sleeve 4 can be moved relatively telescopically; there are two inner slides 6 next to the inner side of the fork slide 5, and the inner slide 6 is adjacent to the fork slide 5 on the side. Only the bearing roller sleeve 4 of the shaft 3 is fixed by the bearing. Similarly, the sliding groove on the other side of the slideway 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com