Y2Ti2O7 pyrochlore self-propagating high-temperature synthesis and densification method

A self-propagating high-temperature, densification technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of long synthesis cycle, complex synthesis process, unfavorable large-scale promotion of pyrochlore solidification process, etc. High density, high product purity, long-term safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] a Y 2 Ti 2 o 7 The self-propagating high-temperature synthesis and densification method of pyrochlore comprises the following steps:

[0046] (1) Use CuO powder as the oxidant and Ti powder as the reducing agent, and mix according to the reaction equation:

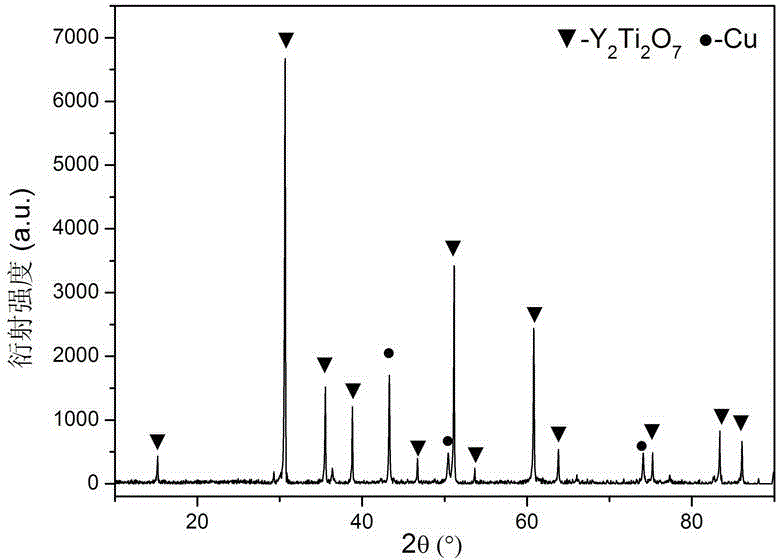

[0047] 6CuO+2Y 2 o 3 +3Ti+TiO 2 =2Y 2 Ti 2 o 7 +6Cu

[0048] The molar ratio of each reactant is CuO:Y 2 o 3 :Ti:TiO 2 =6:2:3:1, according to the respective molecular weight and content, the mass percentage of the corresponding reactant is: CuO: 41.2%, Y 2 o 3 : 39.0%, Ti: 12.9%, TiO 2 : 6.9%.

[0049] (2) Dry grind the weighed raw materials for 20 minutes to mix them evenly, pass the mixed materials through a 100-mesh sieve, take 20g of fully ground raw materials, put them into a Φ25mm steel mold, and cold press them under 20MPa pressure to obtain a diameter A cylindrical blank with a thickness of 25mm and a thickness of about 19mm.

[0050] (3) Put the prepared rough billet into the self-propagati...

Embodiment 2

[0053] a Y 2 Ti 2 o 7 The self-propagating high-temperature synthesis and densification method of pyrochlore comprises the following steps:

[0054] (1) Use CuO powder as the oxidizing agent and Ti powder as the reducing agent, and mix according to the reaction equation:

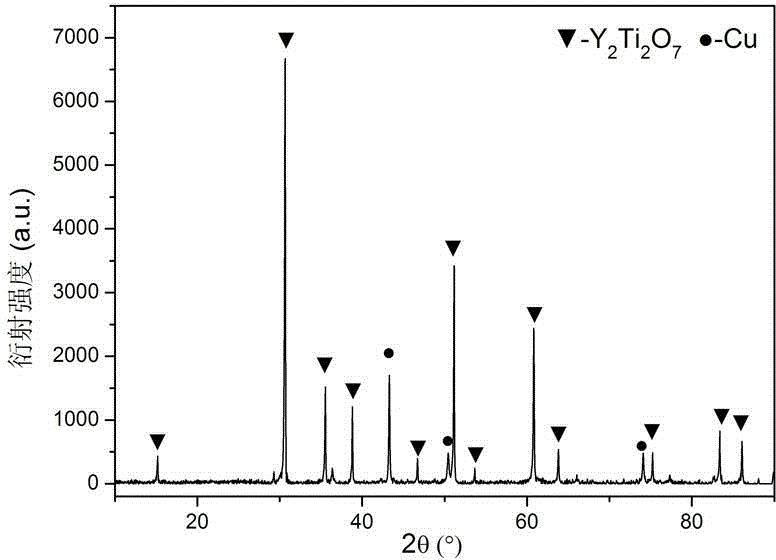

[0055] 2CuO+Y 2 o 3 +Ti+TiO 2 =Y 2 Ti 2 o 7 +2Cu

[0056] The molar ratio of each reactant is CuO:Y 2 o 3 :Ti:TiO 2 =2:1:1:1, according to the respective molecular weight and content, the corresponding mass percentage is: CuO: 31.0%, Y 2 o 3 : 44.0%, Ti: 9.4%, TiO 2 : 15.6%.

[0057] (2) Dry grind the weighed raw materials for 15 minutes to mix them evenly, pass the mixed materials through a 100-mesh sieve, take 25g of fully ground raw materials, put them into a Φ30mm steel mold, and cold press them under a pressure of 40MPa to obtain a diameter A cylindrical blank with a diameter of 40mm and a thickness of about 15mm.

[0058] (3) Put the prepared rough billet into the self-propagating quas...

Embodiment 3

[0061] a Y 2 Ti 2 o 7 The self-propagating high-temperature synthesis and densification method of pyrochlore comprises the following steps:

[0062] a. Ingredients: according to CuO:Y 2 o 3 :Ti:TiO 2 = 6:2:3:1 molar ratio (preferably the purity is higher than 99%, the particle size is less than 200 mesh) CuO, Y 2 o 3 , Ti, TiO 2 powder as raw material;

[0063] b. Abrasives: dry ball mill the above components for 10 minutes, mix them evenly, and pass through 100 sieves to obtain a mixture;

[0064] c. Rough billet compression molding: take 10g of the mixture and put it into a stainless steel mold (cylindrical mold of Φ20mm), and press the mixture into a cylindrical blank 2 with a diameter of 20mm by using a pressure of 10MPa;

[0065] d.Y 2 Ti 2 o 7 Self-propagating high-temperature synthesis and densification of pyrochlore blocks:

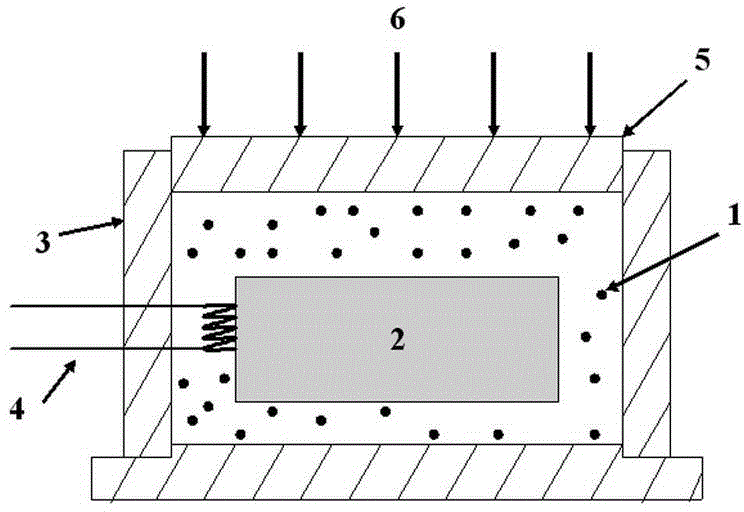

[0066] A self-propagating quasi-isostatic pressing device is adopted. The composition of the device includes an ignition tungsten w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com