Steel wire fixing structure for end of steel wire mesh framework polyethylene composite pipe, and steel wire mesh framework polyethylene composite pipe connecting structure and method

A polyethylene composite pipe and steel wire fixing technology, which is applied in the direction of pipeline connection arrangement, pipes/pipe joints/fittings, pipes, etc., can solve the problems of easy loosening of steel wires, difficult operation, easy leakage, etc., and achieve the effect of avoiding breakage and sealing Good, enhance the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

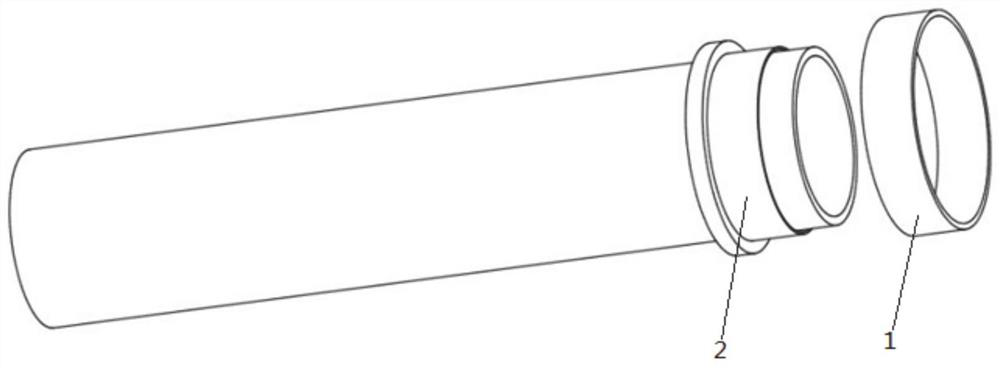

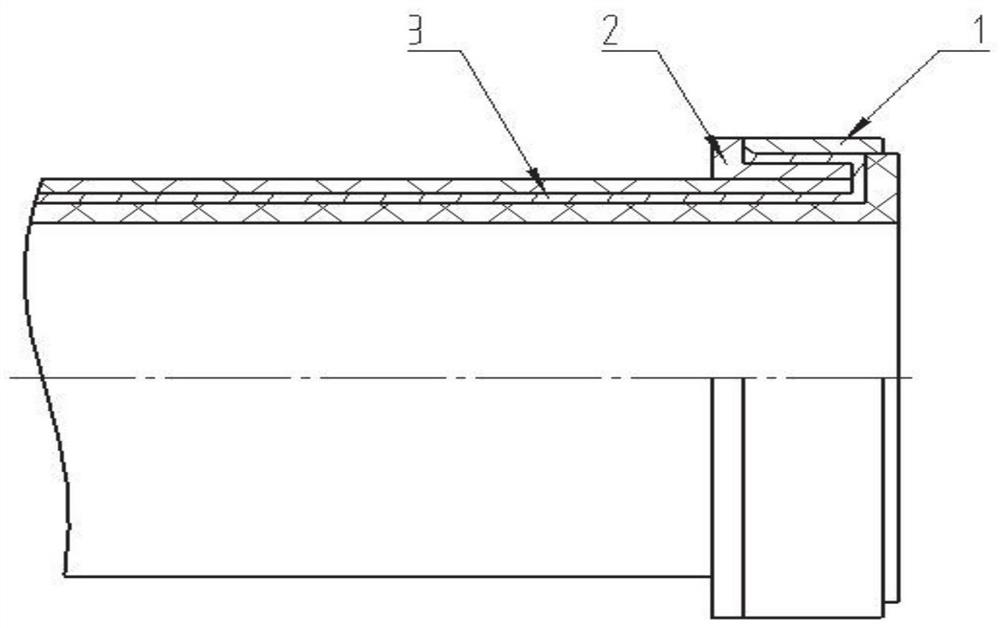

[0046] This embodiment provides a method for fixing the steel wire at the end of a polyethylene composite pipe with a steel mesh skeleton, comprising the following steps:

[0047] 1) Trim the end of the polyethylene composite pipe with steel mesh skeleton, so that the steel wire layer 3 at the end of the polyethylene composite pipe with steel mesh skeleton is flush with the polyethylene layer.

[0048] 2) Nest the inner steel ring 2 on the end of the polyethylene composite pipe with steel mesh skeleton, turn over the polyethylene composite pipe with steel mesh skeleton 180°, and fold it toward the inner steel ring 2 until the edge of the polyethylene composite pipe with steel mesh skeleton Contact with the raised part of the inner steel ring 2.

[0049] 3) Cold treatment is performed on the polyethylene layer at the end, that is, the polyethylene layer is placed in a cold water bath at 2-5°C, and then the outer steel ring 1 is nested outside the steel mesh skeleton polyethylen...

Embodiment 2

[0051] This embodiment provides a method for fixing the steel wire at the end of a polyethylene composite pipe with a steel mesh skeleton. The difference from Embodiment 1 is that in step 2), the polyethylene composite pipe with a steel mesh skeleton is turned over 180°, and the inner steel ring 2 is turned over. Fold until the edge of the steel mesh skeleton polyethylene composite pipe goes over the bulge.

[0052] Step 4) is also included, after the outer steel ring 1 is nested, the excess part of the polyethylene composite pipe of the steel mesh skeleton is cut off.

Embodiment 3

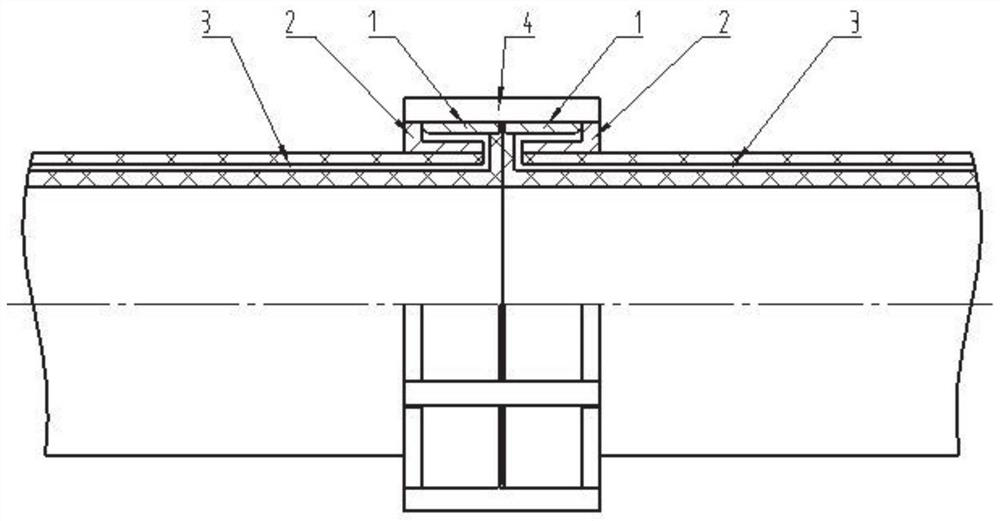

[0054] This embodiment provides a steel mesh skeleton polyethylene composite pipe connection method, including the following steps:

[0055] 1) On the basis of embodiment 1, the polyethylene layers at the ends of two steel wire mesh skeleton polyethylene composite pipes are hot-melt welded;

[0056] 2) Clamp the two opposite inner steel rings 2 inwardly along the edge where the protrusion is located, and weld the connecting piece 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com