A kind of air or pure oxygen catalytic oxidation hydrogen bromide prepares the method for 2,3,5-tribromothiophene

A technology of tribromothiophene and catalytic oxidation, applied in directions such as organic chemistry, can solve problems such as the utilization rate of bromine, and achieve the effects of low production cost, simple post-treatment and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

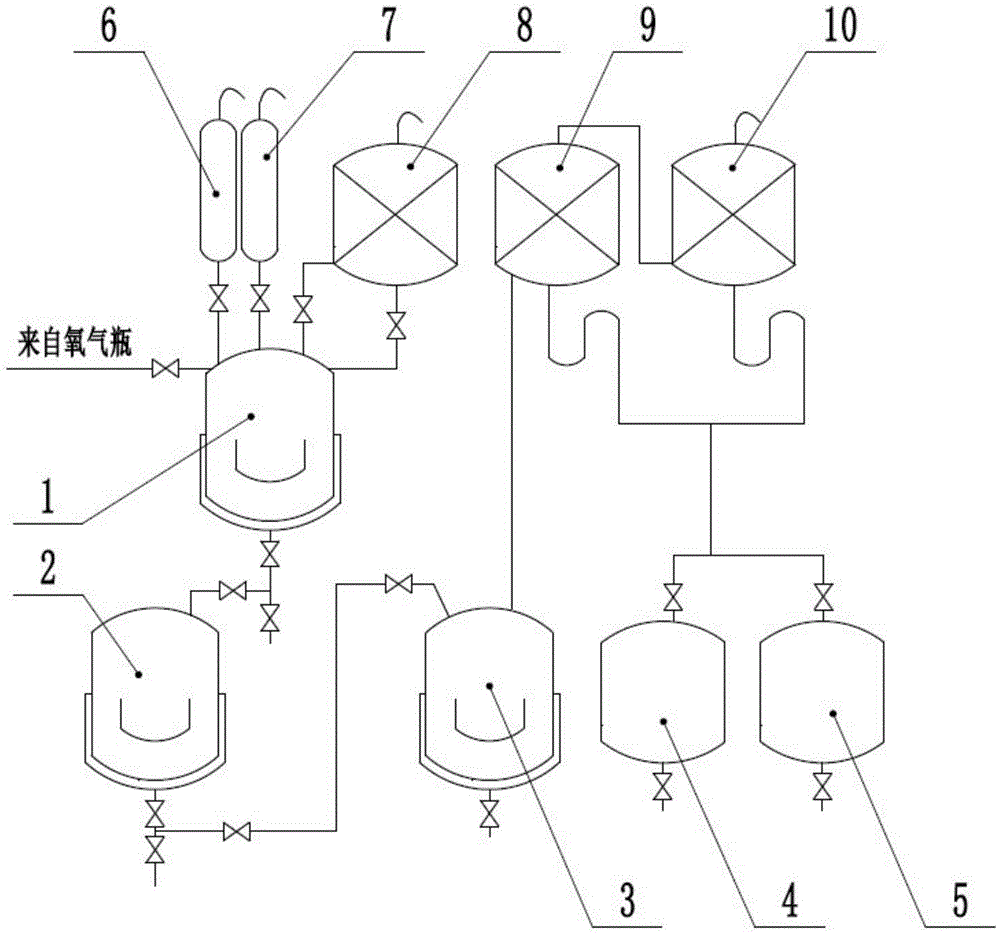

[0014] a. Put 35L of chloroform, 16.8kg of thiophene and 0.168kg of copper bromide into reactor 1, and stir for 10 minutes. When reactor 1 was cooled to -5°C with jacket water, 65.0kg of bromine was added dropwise from drop tank I6. into Reactor 1.

[0015] B. After the reaction starts, air or pure oxygen is blown into the reactor 1. After the bromine is slowly added dropwise, the reactor 1 is slowly heated to reflux. The gas is refluxed into the reactor 1 after being condensed by the reflux condenser 8, and the reaction After 3.5 hours, cool to 23°C-25°C;

[0016] c. Add 10 L of 0.05 mol / L ethanol solution of sodium hydroxide dropwise to Reactor 1 from dropping tank II 7 to decompose unreacted bromine, and stir for 30 minutes.

[0017] d. Put the reaction mixture into the water washing kettle 2, add 35L of water, fully stir for 30 minutes, let it stand, and put the lower organic phase into the distillation kettle 3 for atmospheric distillation, and the gas passes through the...

Embodiment 2

[0019] a. Put 35L of chloroform, 16.8kg of thiophene and 0.168kg of sodium nitrite into the reaction kettle 1, and stir for 10 minutes. When the reaction kettle 1 was cooled to -5°C with the jacket water, 65.0kg of bromine was added dropwise from the dropping tank I6. into Reactor 1.

[0020] B. After the reaction starts, air or pure oxygen is blown into the reactor 1. After the bromine is slowly added dropwise, the reactor 1 is slowly heated to reflux. The gas is refluxed into the reactor 1 after being condensed by the reflux condenser 8, and the reaction After 5 hours, cool to 23°C-25°C;

[0021] c. Add 10 L of 0.05 mol / L ethanol solution of sodium hydroxide dropwise to Reactor 1 from dropping tank II 7 to decompose unreacted bromine, and stir for 30 minutes.

[0022] d. Put the reaction mixture into the water washing kettle 2, add 35L of water, fully stir for 30 minutes, let it stand, and put the lower organic phase into the distillation kettle 3 for atmospheric distillati...

Embodiment 3

[0024] a. Put 35L of chloroform, 16.8kg of thiophene and 0.168kg of ferric bromide into the reaction kettle 1, and stir for 10 minutes. When the reaction kettle 1 was cooled to -5°C with the jacket water, 65.0kg of bromine was added dropwise from the dropping tank I6. into Reactor 1.

[0025] B. After the reaction starts, air or pure oxygen is blown into the reactor 1. After the bromine is slowly added dropwise, the reactor 1 is slowly heated to reflux. The gas is refluxed into the reactor 1 after being condensed by the reflux condenser 8, and the reaction After 3.5 hours, cool to 23°C-25°C;

[0026] c. Add 10 L of 0.05 mol / L ethanol solution of sodium hydroxide dropwise to Reactor 1 from dropping tank II 7 to decompose unreacted bromine, and stir for 30 minutes.

[0027] d. Put the reaction mixture into the water washing kettle 2, add 35L of water, fully stir for 30 minutes, let it stand, and put the lower organic phase into the distillation kettle 3 for atmospheric distilla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap