Anti-pollution silicone weather-resistant sealant and preparation method thereof

An anti-pollution and sealant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of sloping pollution, waste of manpower and time, and infiltration of curtain wall panels, to prevent infiltration of pollution, Effects of reduced adsorption and accumulation, high displacement capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

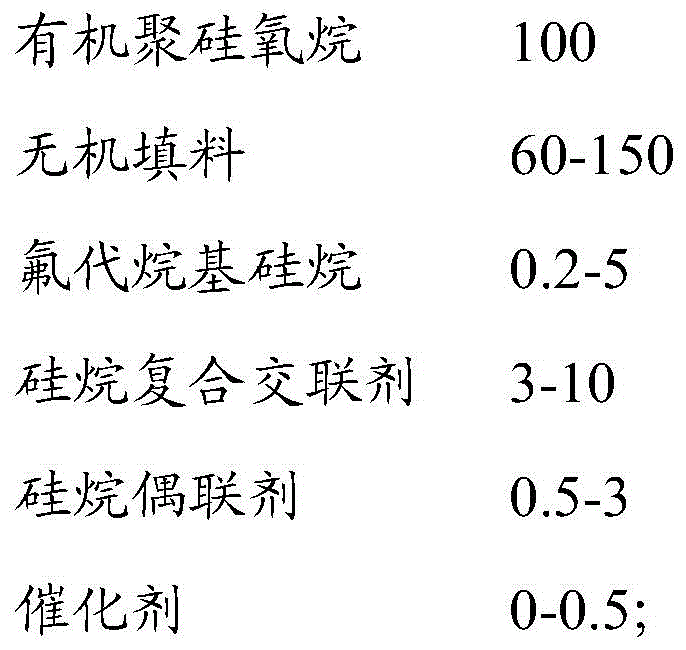

[0032] An anti-pollution silicone sealant in this embodiment includes the following raw materials in parts by weight:

[0033] 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa.s, 90 parts of nano-active calcium carbonate, 6 parts of methyl tributylketoxime silane, 3 parts of diphenyl dibutylketoxime silane , 1 part of aminopropyltriethoxysilane, 0.8 part of tridecafluorooctyltrimethoxysilane, and 0.06 part of dibutyltin dilaurate.

[0034] The preparation method of the above-mentioned anti-pollution silicone sealant is as follows:

[0035] Add α,ω-dihydroxypolydimethylsiloxane and nano-active calcium carbonate into the kneader, dehydrate and blend for 100min at 100°C and a vacuum of 0.09MPa, and obtain the base material after cooling;

[0036] At room temperature, add the above-mentioned base material into a planetary mixer or a high-speed dispersion mixer, and then add methyl tributylketoxime silane, diphenyl dibutylketoxime silane, aminopropyl t...

Embodiment 2

[0038] An anti-pollution silicone sealant in this embodiment includes the following raw materials in parts by weight:

[0039] 85 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 50000mPa.s, 15 parts of single-ended hydroxyl polydimethylsiloxane with a viscosity of 1000mPa.s, 80 parts of nano-active calcium carbonate, and heavy calcium carbonate 30 parts, 6 parts of phenyl tributylketoxime silane, 4 parts of methyl vinyl dibutyl ketoxime silane, 1 part of aminopropyl triethoxysilane, γ-glycidyl ether oxypropyl trimethoxysilane 0.3 parts, 1.5 parts of heptadecafluorodecyltrimethoxysilane.

[0040] The preparation method of the above-mentioned anti-pollution silicone sealant is as follows:

[0041] Add α,ω-dihydroxy polydimethylsiloxane, single-end hydroxyl polydimethylsiloxane, nano-active calcium carbonate and heavy calcium carbonate into the kneader, at 120°C, the vacuum degree is 0.08MPa Down, dehydration blending 200min, after cooling, base material is obta...

Embodiment 3

[0044] An anti-pollution silicone sealant in this embodiment includes the following raw materials in parts by weight:

[0045] 80 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mPa.s, 20 parts of single-end hydroxyl polydimethylsiloxane with a viscosity of 500mPa.s, 80 parts of nano-active calcium carbonate, and heavy calcium carbonate 40 parts, 2 parts of tetrabutylketoxime silane, 4 parts of methyl tributylketoxime silane, 2 parts of dimethylbis(N-methylacetamido) silane, N-beta aminoethyl γ-aminopropyl 1 part of trimethoxysilane, 2.0 parts of heptadecafluorodecyltriethoxysilane, and 0.03 part of dimethyltin dineodecanoate.

[0046] The preparation method of the above-mentioned anti-pollution silicone sealant is as follows:

[0047] Add α,ω-dihydroxy polydimethylsiloxane, single-end hydroxyl polydimethylsiloxane, nano-active calcium carbonate and heavy calcium carbonate into the kneader, at 140°C, the vacuum degree is 0.09MPa Down, dehydration blendin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com