Preparation method of low-density high-magnification epoxy resin microporous material

The technology of epoxy resin and microporous material is applied in the field of preparation of low density and high rate epoxy resin microporous material, and can solve the problems of low expansion rate of foamed material and high foam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

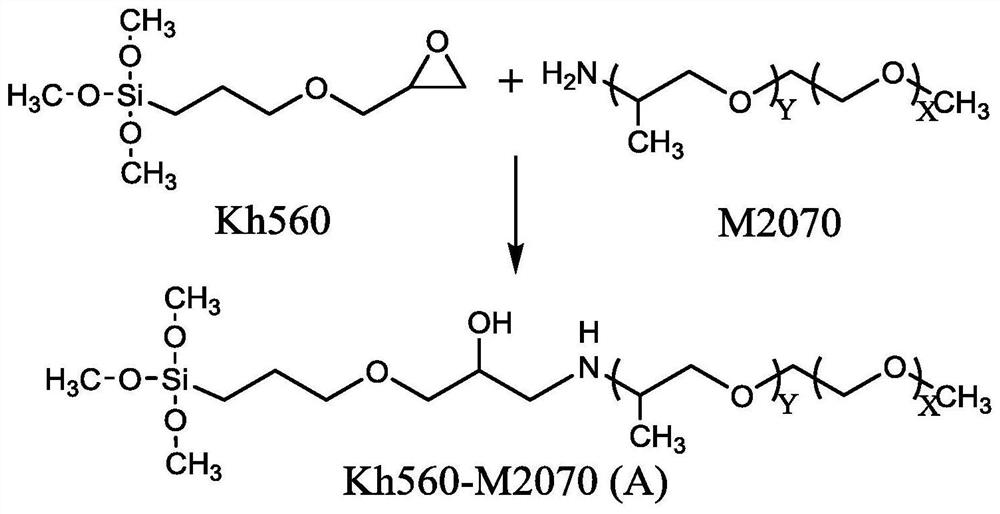

[0026] Step 1. Add M-2070 polyetheramine and 3-glycidyloxypropyl trimethylsiloxane to 340g of absolute ethanol at a mass ratio of 10:1, and react under magnetic stirring conditions at 46°C After 10 hours, the reactant solution was dried to obtain a yellow waxy viscous fluid, and the sample was marked as A;

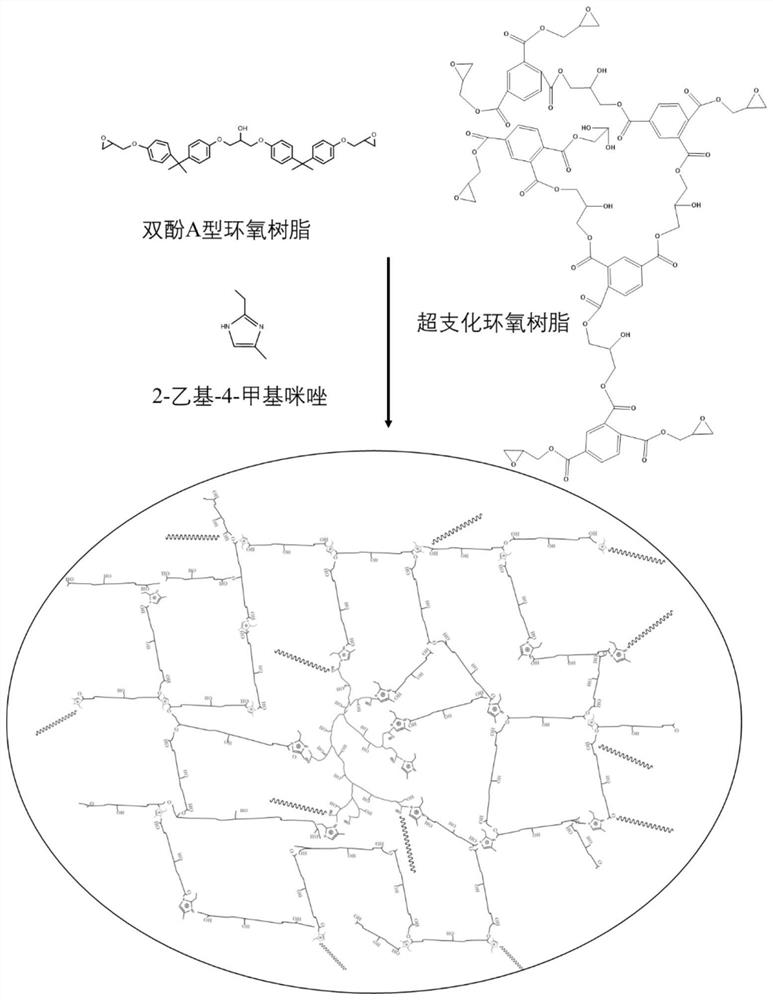

[0027] Step 2, add bisphenol A epoxy resin, hyperbranched epoxy resin and 2-ethyl-4-methylimidazole into dichloromethane according to the mass ratio of 90:10:4.54, and turn on the magnetic stirrer at 500 rpm / min was stirred for 6 hours to obtain a mixed solution, and the resulting sample was marked as B;

[0028] Step 3. The two samples of A and B are added to the mixed solution in step 2 according to the mass ratio of 1:100, stirred magnetically for 5 hours, and dried in a vacuum oven at 35°C to obtain epoxy resin powder. The obtained sample is marked as C;

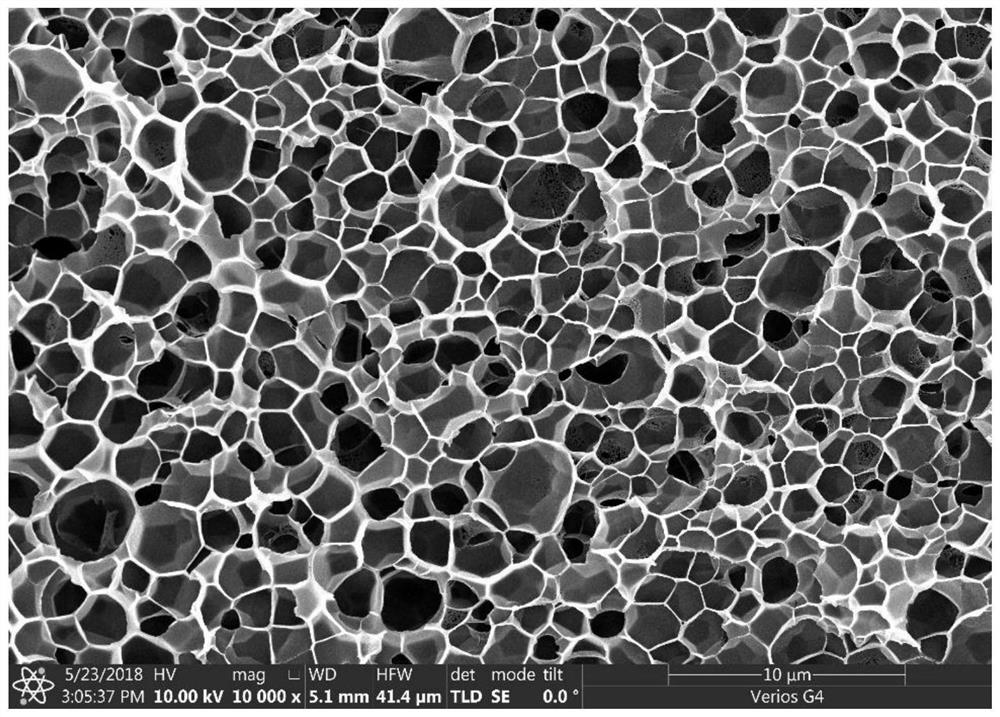

[0029] Step 4. Place sample C in a hot press, heat press at 125°C, 10MPa pressure and 8 hours, and then naturally...

Embodiment 2

[0034] Step 1. Add M-2070 polyetheramine and 3-glycidyloxypropyl trimethylsiloxane into 300g of absolute ethanol at a mass ratio of 9:1, and react under magnetic stirring conditions at 45°C After 15 hours, the reactant solution was dried to obtain a yellow waxy viscous fluid, and the sample was marked as A;

[0035] Step 2. Add bisphenol A epoxy resin, hyperbranched epoxy resin and 2-ethyl-4-methylimidazole into dichloromethane according to the mass ratio of 90:10:4.54, and turn on the magnetic stirrer at 600 rpm / min was stirred for 5 hours to obtain a mixed solution, and the resulting sample was marked as B;

[0036] Step 3. Add A and A samples into the mixed solution in step 2 according to the mass ratio of 3:100, stir magnetically for 4 hours, and dry the mixed solution in a vacuum oven at 31°C to obtain epoxy resin powder , the obtained sample is marked as C;

[0037] Step 4. Place sample C in a hot press, heat press under the conditions of 100°C temperature, 20MPa pres...

Embodiment 3

[0042] Step 1. Add M-2070 polyetheramine and 3-glycidyloxypropyl trimethylsiloxane into 350g of absolute ethanol at a mass ratio of 8:1, and react under magnetic stirring conditions at 50°C After 14 hours, the reactant solution was dried to obtain a yellow waxy viscous fluid, and the sample was marked as A;

[0043] Step 2. Add bisphenol A epoxy resin, hyperbranched epoxy resin and 2-ethyl-4-methylimidazole into dichloromethane according to the mass ratio of 90:10:4.54, and turn on the magnetic stirrer at 700 rpm The rotating speed of / min was stirred for 4 hours to obtain the mixed solution, and the obtained sample was marked as B;

[0044] Step 3: Add A and B samples into the mixed solution in step 2 according to the mass ratio of 5:100, add A sample to the mixed solution in step 2, stir the mixed solution for 3 hours, and dry the mixed solution in a vacuum oven at 33°C to obtain epoxy resin powder , the obtained sample is marked as C;

[0045] Step 4. Put the sample C und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com