Metal organic framework material modified PEO-based fire safety type solid polymer electrolyte and preparation method thereof

A metal-organic framework and solid polymer technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problem of flammability reduction, fire safety of lithium-ion battery systems, safety cannot be guaranteed, and poor electrochemical stability and other issues, to achieve the effect of improving electrochemical stability and ionic conductivity, improving fire safety, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

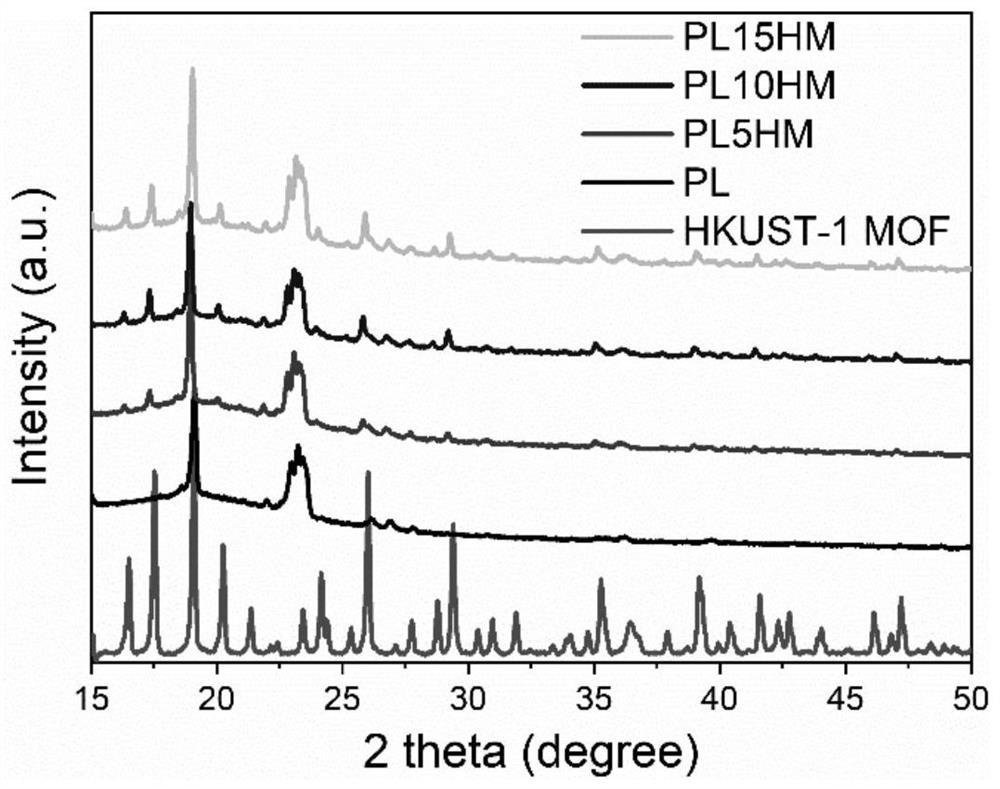

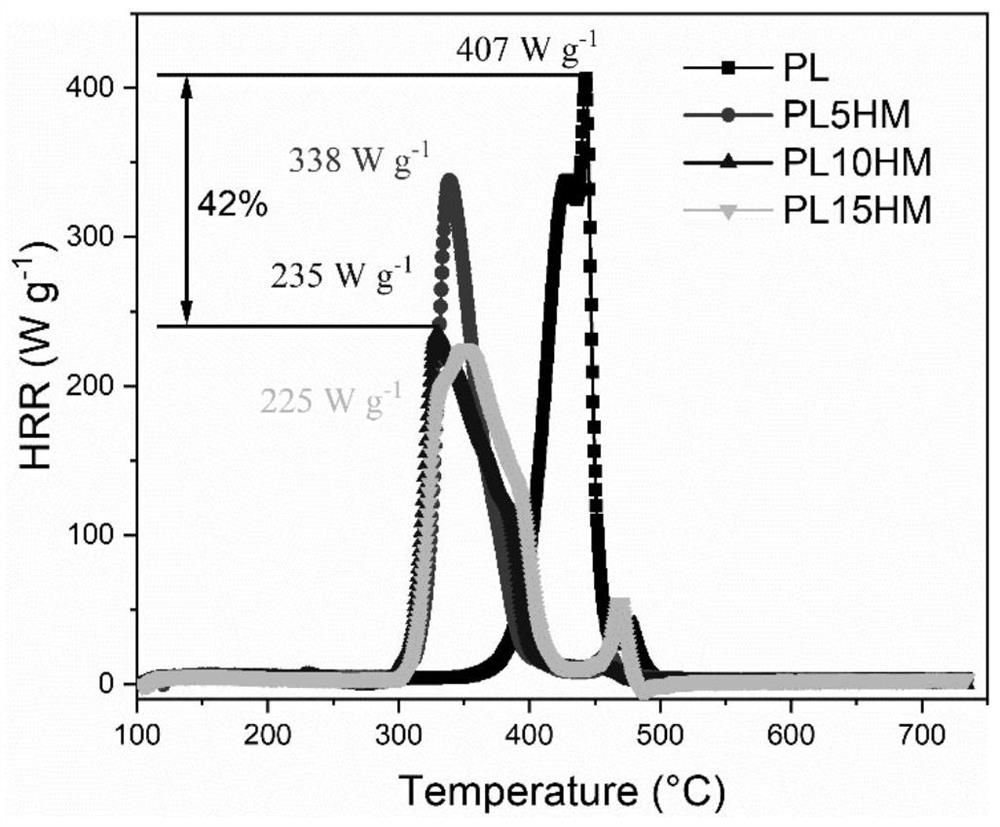

[0035] Step 1: LiTFSI, PEO (M w =9×10 5 gmol -1 ), HKUST-1 MOF materials were dried in a vacuum oven at 50°C for 24 hours, and placed in a glove box for later use.

[0036] Step 2: Weigh PEO, LiTFSI and HKUST-1 obtained in step 1 in proportion, the mass of HKUST-1 is 5%wt of the total mass of the polymer substrate and lithium salt, control EO: Li + The molar ratio is 15:1. Put the weighed drug into a beaker, add acetonitrile (the mass is 9 times the total mass of the weighed drug), and stir vigorously at room temperature for 12 hours.

[0037] Step 3: Pour the obtained solution onto a polytetrafluoroethylene plate, let it advect naturally, and evaporate the solvent in a fume hood at room temperature.

[0038] Step 4: Tear off the film and place it in a polytetrafluoroethylene petri dish, and dry it in a vacuum oven at 60°C for 12 hours to further remove the solvent to obtain HKUST-1 as a modified filler PEO-based fire-safe solid polymer electrolyte.

Embodiment 2

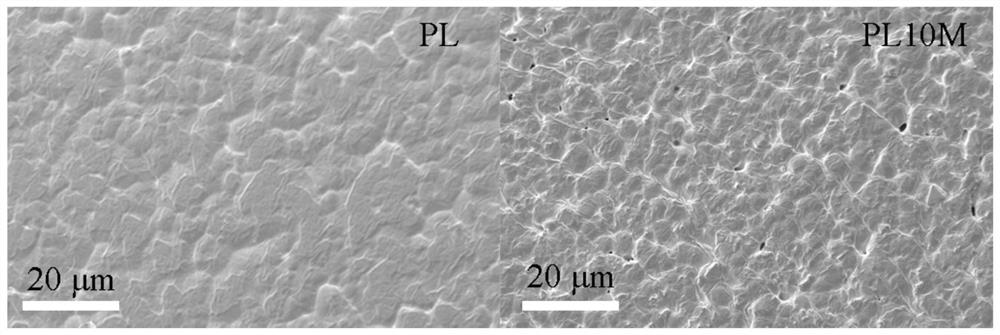

[0040] Step 1: LiTFSI, PEO (M w =9×10 5 gmol -1 ), HKUST-1 MOF materials were dried in a vacuum oven at 50°C for 24 hours, and placed in a glove box for later use.

[0041] Step 2: Weigh the PEO, LiTFSI and HKUST-1 obtained in Step 1 in proportion. The mass of HKUST-1 is 10%wt of the total mass of the polymer substrate and lithium salt. Control EO: Li + The molar ratio is 15:1. Put the weighed drug into a beaker, add acetonitrile (the mass is 9 times the total mass of the weighed drug), and stir vigorously at room temperature for 12 hours.

[0042] Step 3: Pour the obtained solution onto a polytetrafluoroethylene plate, let it advect naturally, and evaporate the solvent in a fume hood at room temperature.

[0043] Step 4: Tear off the film and place it in a polytetrafluoroethylene petri dish, and dry it in a vacuum oven at 60°C for 12 hours to further remove the solvent to obtain HKUST-1 as a modified filler PEO-based fire-safe solid polymer electrolyte.

Embodiment 3

[0045] Step 1: LiTFSI, PEO (M w =9×10 5 gmol -1 ), HKUST-1 MOF materials were dried in a vacuum oven at 50°C for 24 hours, and placed in a glove box for later use.

[0046] Step 2: Weigh the PEO, LiTFSI and HKUST-1 obtained in Step 1 in proportion, the mass of HKUST-1 is 15%wt of the total mass of the polymer substrate and lithium salt, control EO: Li + The molar ratio is 15:1. Put the weighed drug into a beaker, add acetonitrile (the mass is 9 times the total mass of the weighed drug), and stir vigorously at room temperature for 12 hours.

[0047] Step 3: Pour the obtained solution onto a polytetrafluoroethylene plate, let it advect naturally, and evaporate the solvent in a fume hood at room temperature.

[0048] Step 4: The membrane was torn off and placed in a polytetrafluoroethylene petri dish, and dried in a vacuum oven at 60°C for 12 hours to further remove the solvent to obtain HKUST-1 as a modified filler based on PEO-based fire-safe solid polymer electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com