Solid polymer electrolyte membrane and preparation method thereof

A technology of solid polymer and electrolyte membrane, which is applied in the direction of electrolyte, non-aqueous electrolyte battery, electrolyte immobilization/gelation, etc. It can solve the problems of low mechanical strength, weak chain segment movement ability, low melting point, etc., and achieve the improvement of mechanical Performance and heat resistance, improvement of ion conductivity, effect of high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

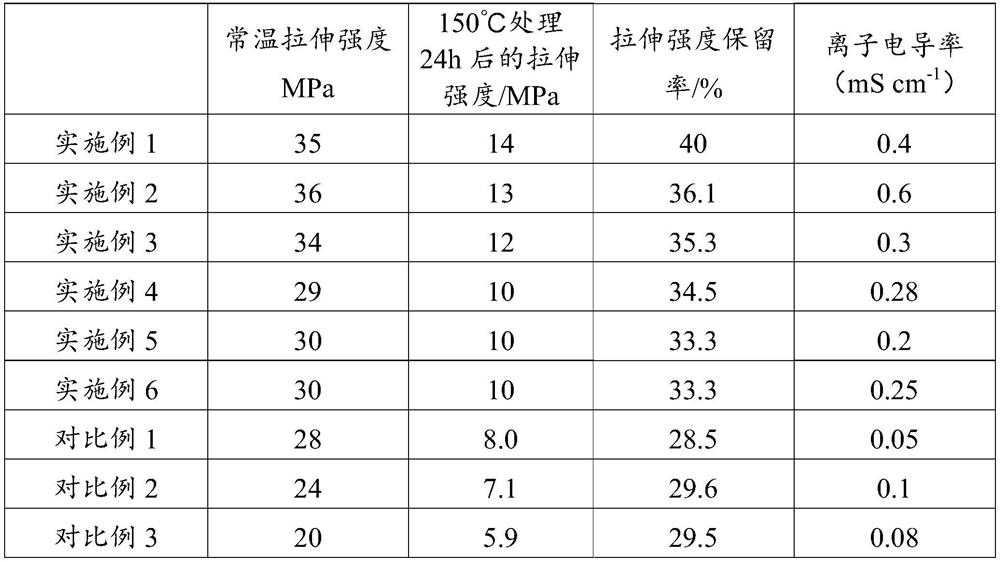

Examples

preparation example Construction

[0045] Correspondingly, the present invention also provides a method for preparing the above-mentioned solid polymer electrolyte membrane, comprising the following steps:

[0046] S1, in parts by weight, combine 800-1200 parts of rubber materials, 800-1200 parts of operating aids, 400-600 parts of fillers, 400-600 parts of lithium salts, 0.1-3 parts of ZnO, 0.01-0.5 parts of stearic acid, 0.1-3 parts of vulcanizing agent and 2-8 parts of accelerator are mixed to obtain a first mixture; the vulcanizing agent includes sulfur and / or sulfur donor.

[0047] Preferably, the rubber material is selected from one or a combination of natural rubber, styrene-butadiene rubber, butyl rubber, nitrile rubber, neoprene rubber, and EPDM;

[0048] Described operation aid includes operation oil or plasticizer; Specifically, described operation aid selects dioctyl phthalate, dimethyl phthalate, diethyl phthalate, phthalic acid One or a combination of di-n-butyl ester, paraffin oil, naphthenic oi...

Embodiment 1

[0061] This embodiment provides a preparation method of a solid polymer electrolyte membrane:

[0062] S1. Mix 1000g EPDM, 0.5g ZnO, 0.1g stearic acid, 500g Al 2 O 3 , 1000g of paraffin oil, 500g of LiTFSI, 1g of thiuram compound and 6g of aldehyde amine accelerator are mixed into the agent to obtain the first mixture;

[0063] S2, put the first mixture into the Banbury mixing equipment, carry out Banbury mixing under the condition of 80 ℃, obtain the mixed rubber;

[0064] S3. Add the mixed rubber to a pair of roll mills, adjust the temperature of the opposite rolls to 80°C, and calender the mixed rubber into a film to obtain a mixed rubber film; the mixed rubber film is kept at 150° C. The finished product is obtained after 5 minutes.

Embodiment 2

[0066] This embodiment provides a preparation method of a solid polymer electrolyte membrane:

[0067] S1. Mix 1000g EPDM, 0.5g ZnO, 0.1g stearic acid, 500g Al 2 O 3 , 1000g paraffin oil, 500g LiTFSI, 2g thiuram compound and 6g aldehyde amine accelerator are mixed into the agent to obtain the first mixture;

[0068] S2, put the first mixture into the Banbury mixing equipment, carry out Banbury mixing under the condition of 80 ℃, obtain the mixed rubber;

[0069] S3. Add the mixed rubber to a pair of roll mills, adjust the temperature of the opposite rolls to 80°C, and calender the mixed rubber into a film to obtain a mixed rubber film; the mixed rubber film is kept at 150° C. The finished product is obtained after 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com