Preparation method of high-low-temperature-resistant lithium ion battery

A lithium-ion battery, high and low temperature resistant technology, applied in the direction of secondary battery, battery pack parts, secondary battery repair/maintenance, etc., can solve the problems of high temperature resistance, low temperature resistance and other problems, to avoid side reactions, Improve cycle performance, suppress the effects of decomposition and co-embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for a high-low temperature resistant lithium-ion battery, comprising the steps of:

[0029] Step 1: Assemble the positive electrode sheet, negative electrode sheet and separator together, and then wind them into a core to obtain a battery cell;

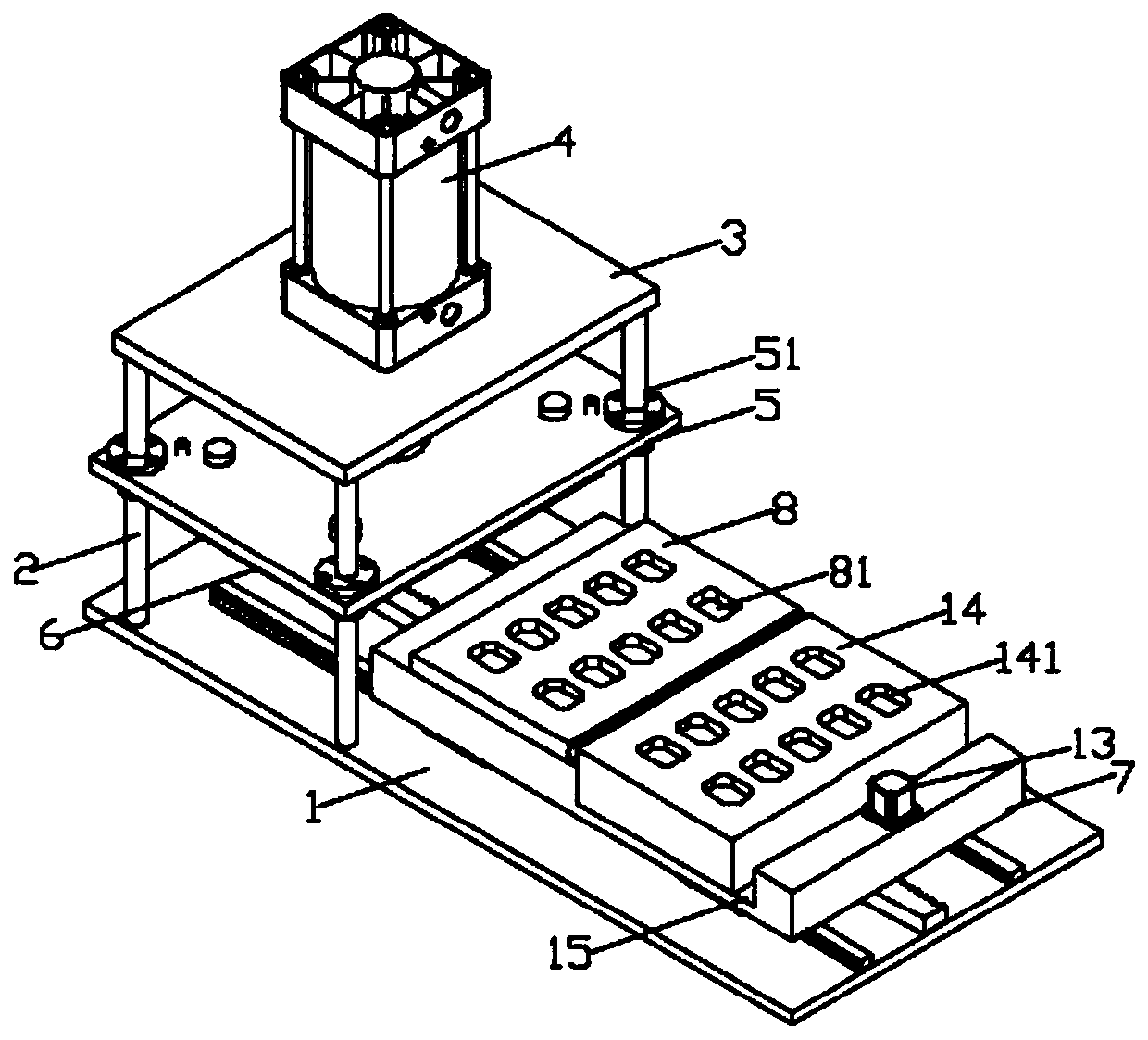

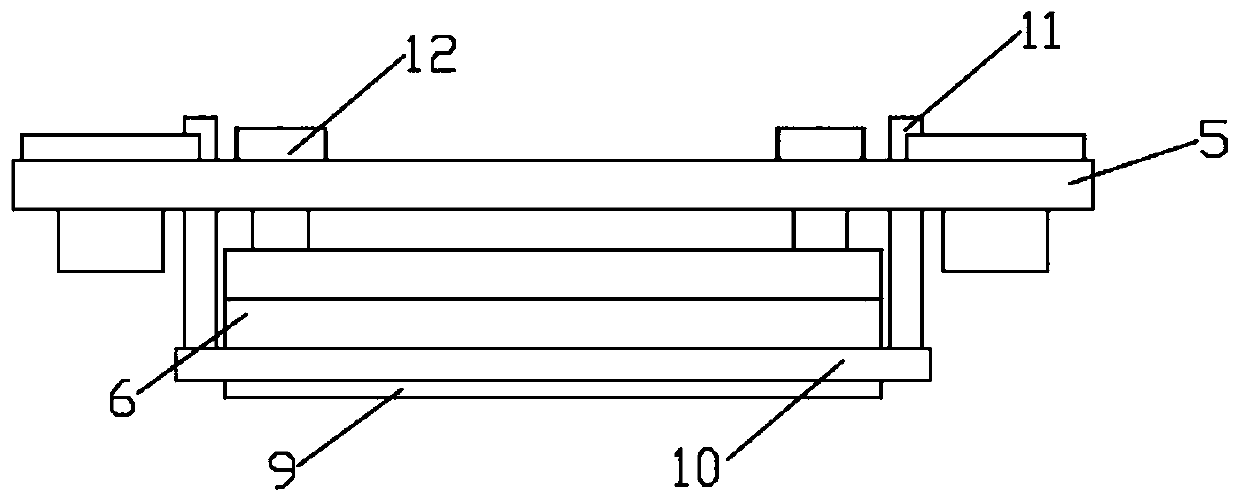

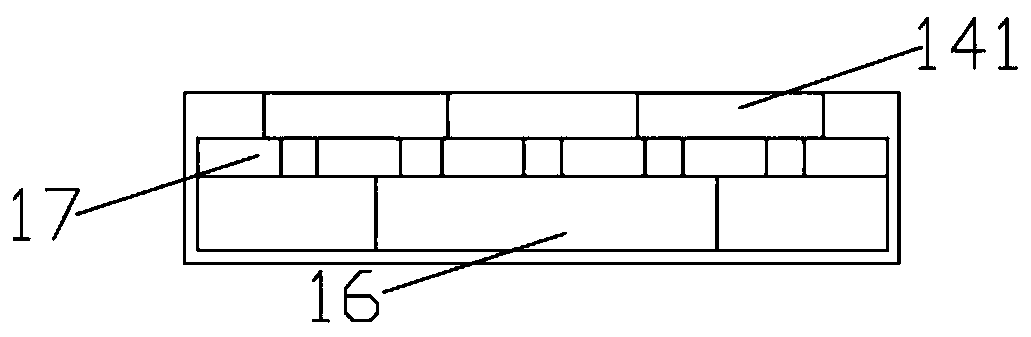

[0030] Step 2: Put the battery cells into the shell, apply a layer of acrylic adhesive on the top of the shell, and put the shell with the acrylic adhesive face up into the lithium battery slot on the lower slot plate of the capping equipment, Then the output shaft of the drive motor drives the gear to rotate, the gear meshes with the rack to drive the moving plate to move, the moving plate moves down the top plate along the slide rail on the installation platform through the slider at the bottom, and after the lower groove plate moves to the bottom of the top plate, the telescopic cylinder piston rod Push the lifting plate downward, the lifting plate drives the heating template down through the connecting ...

Embodiment 2

[0035] The electrolyte is prepared from the following raw materials in parts by weight: 10 parts of lithium salt, 94 parts of solvent and 10 parts of additive; the preparation method of the additive includes the following steps: under the combined action of heating and catalyst, VC, PS Carry out cycloaddition reaction with VEC solvent, the heating temperature is 80°C, and the reaction time is 3h. After the reaction is completed, the catalyst is removed by filtration, and the residual material is purified to obtain the additive. The catalyst is alkaline earth metal hydroxide; the lithium salt is lithium hexafluorophosphate, lithium bisoxalate borate, lithium difluorooxalate borate, lithium bisfluorosulfonimide; the solvent is ethylene carbonate, diethyl carbonate, carbonic acid Acrylate. The diaphragm is polyethylene film, polypropylene film, aramid fiber film, the thickness of the diaphragm is 20 μm, and the porosity is 50%. The positive electrode sheet includes a positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com