A preparation method of a chrome-free tanned leather retanning agent based on hydrogen bond self-assembly

A self-assembly, chrome-free tanning technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, animal husbandry, etc. With the retanning function, the retanning filling performance cannot be significantly improved, etc., to achieve good retanning filling performance, good retanning filling effect, and enhanced hydrogen bond assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

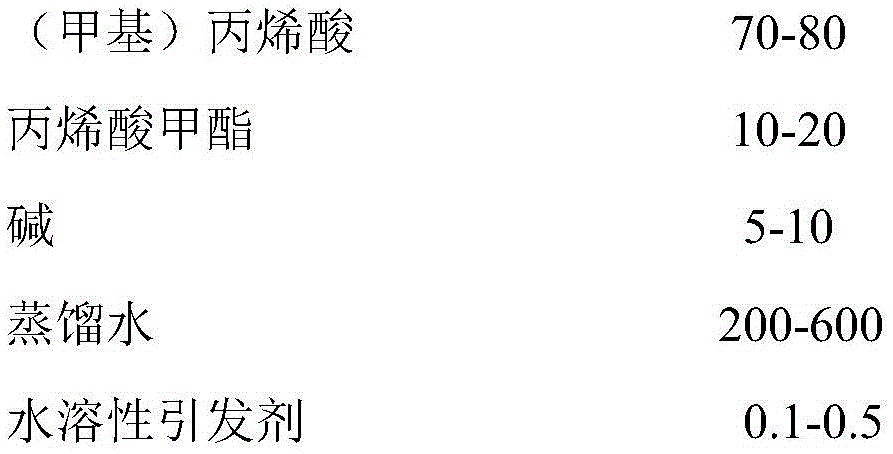

[0042] 1. Synthesis of (meth)acrylic resin

[0043] Add 140 g of distilled water, 16.3 g of acrylic acid monomer and 2.3 g of methyl acrylate into a four-necked flask with a stirrer and a reflux condenser. Start the stirrer, stir and mix for 30 minutes; add 0.02g ammonium persulfate, continue stirring for 10 minutes, then raise the temperature to 80°C; System pH to 6.0. That is, a (meth)acrylic resin with a solid content of 10 wt % was obtained.

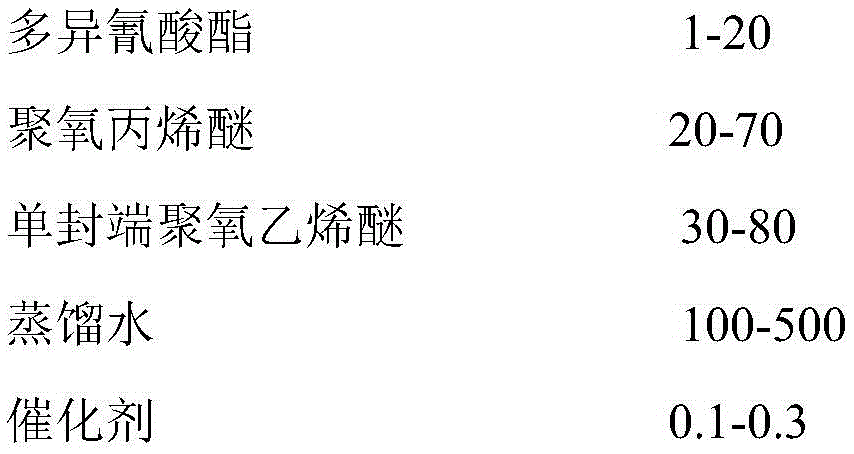

[0044] 2. Synthesis of Triblock Nonionic Amphiphilic Polyurethane Resin

[0045] Under the conditions of 120° C. and a vacuum of 0.09 MPa, the polyoxypropylene ether and the mono-blocked polyoxyethylene ether were distilled under reduced pressure for 120 minutes to remove moisture. Add 5.6g of polyoxypropylene ether with a molecular weight of 1000 to a four-necked bottle with a stirrer and a thermometer, heat to 80°C while stirring, add 0.0lg of dibutyltin dilaurate, stir and mix for 10min, then add 2.8g dropwise The toluene diis...

Embodiment 2

[0049] 1. Synthesis of (meth)acrylic resin

[0050] Add 140 g of distilled water, 16.3 g of methacrylic acid monomer and 2.3 g of methyl acrylate into a four-necked flask equipped with a stirrer and a reflux condenser. Start the stirrer, stir and mix for 30 minutes; add 0.02g ammonium persulfate, continue stirring for 10 minutes, then raise the temperature to 80°C; System pH to 6.0. That is, a (meth)acrylic resin with a solid content of 10 wt % was obtained.

[0051] 2. Synthesis of Triblock Nonionic Amphiphilic Polyurethane Resin

[0052] Under the conditions of 120° C. and a vacuum of 0.09 MPa, the polyoxypropylene ether and the mono-blocked polyoxyethylene ether were distilled under reduced pressure for 120 minutes to remove moisture. Add 5.6g of polyoxypropylene ether with a molecular weight of 1000 to a four-necked bottle with a stirrer and a thermometer, heat to 80°C while stirring, add 0.0lg of dibutyltin dilaurate, stir and mix for 10min, then add 2.8g dropwise The...

Embodiment 3

[0056] 1. Synthesis of (meth)acrylic resin

[0057] Add 140 g of distilled water, 16.3 g of acrylic acid monomer and 2.3 g of methyl acrylate into a four-necked flask with a stirrer and a reflux condenser. Start the stirrer, stir and mix for 30 minutes; add 0.02g ammonium persulfate, continue stirring for 10 minutes, then raise the temperature to 80°C; System pH to 6.0. That is, a (meth)acrylic resin with a solid content of 10 wt % was obtained.

[0058] 2. Synthesis of Triblock Nonionic Amphiphilic Polyurethane Resin

[0059] Under the conditions of 120° C. and a vacuum of 0.09 MPa, the polyoxypropylene ether and the mono-blocked polyoxyethylene ether were distilled under reduced pressure for 120 minutes to remove moisture. Add 5.6g of polyoxypropylene ether with a molecular weight of 2000 to a four-necked bottle with a stirrer and a thermometer, heat to 80°C while stirring, add 0.0lg of dibutyltin dilaurate, stir and mix for 10min, then add 2.8g dropwise The isophorone d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com