Bi-directional traction vertical rotation construction device for cable-stayed bridge steel arch tower

A cable-stayed bridge steel and two-way traction technology, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of large construction load, increased risk, and high risk, so as to reduce weight, increase safety, and avoid loosening anchor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

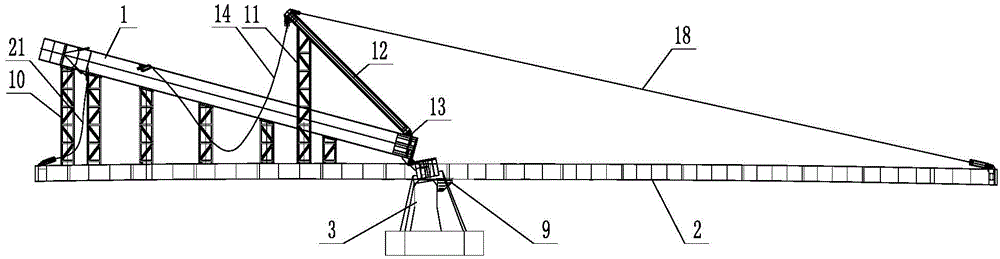

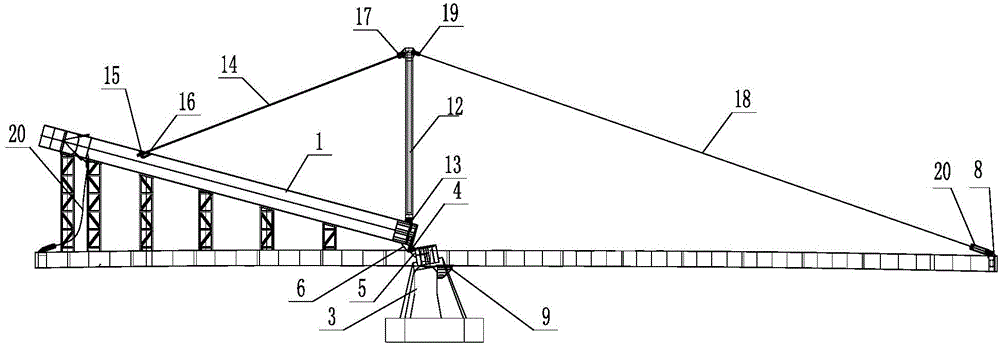

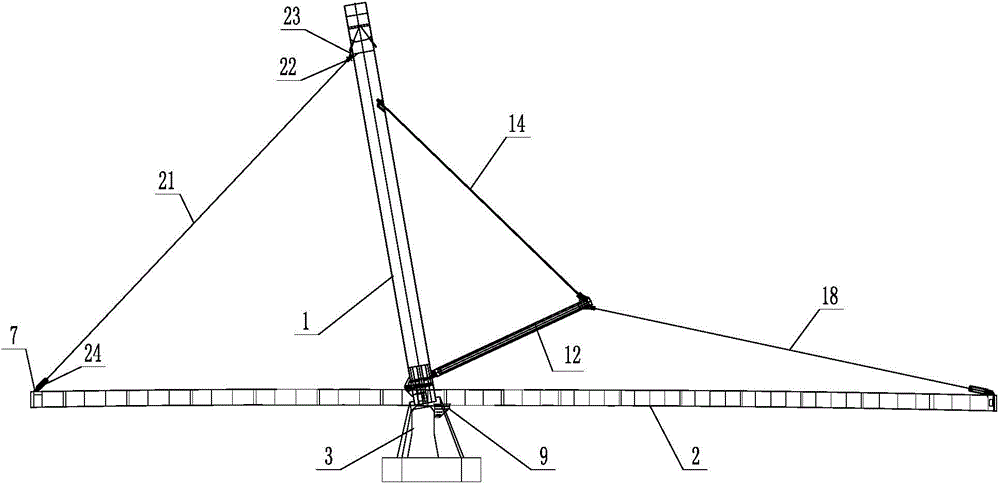

[0030] Such as Figure 1-7 As shown, a cable-stayed bridge steel arch tower two-way traction vertical rotation construction device includes a vertical rotation hinge 4, an anti-slip support 9, a steel arch tower assembly tire frame 10, a vertical rotation frame assembly tire frame 11, and a vertical rotation frame 12 , Vertical swivel frame hinge seat 13, front cable 14, rear cable 18, balance cable 21, stabilizing cable 25;

[0031] The vertical hinge 4 is composed of the lower hinge seat 5 and the upper hinge seat 6 of the vertical hinge. The lower hinge seat 5 of the vertical hinge is fixed (such as welded) to the pre-buried section of the arch foot of the steel arch tower on the main structure 3 of the pier body Upper; the lower hinge seat 5 of the vertical hinge is hinged with the upper hinge seat 6 of the vertical hinge; the upper hinge seat 6 of the vertical hinge is fixed (such as welded) on the arch foot segment of the steel arch tower 1 (the steel arch tower 1 has tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com