Pressure stabilizing valve of adjustable pressure type turbocharger

A technology of turbocharger and pressure stabilizing valve, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., and can solve problems such as the adjustment of the maximum intake pressure value of engines that cannot be boosted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

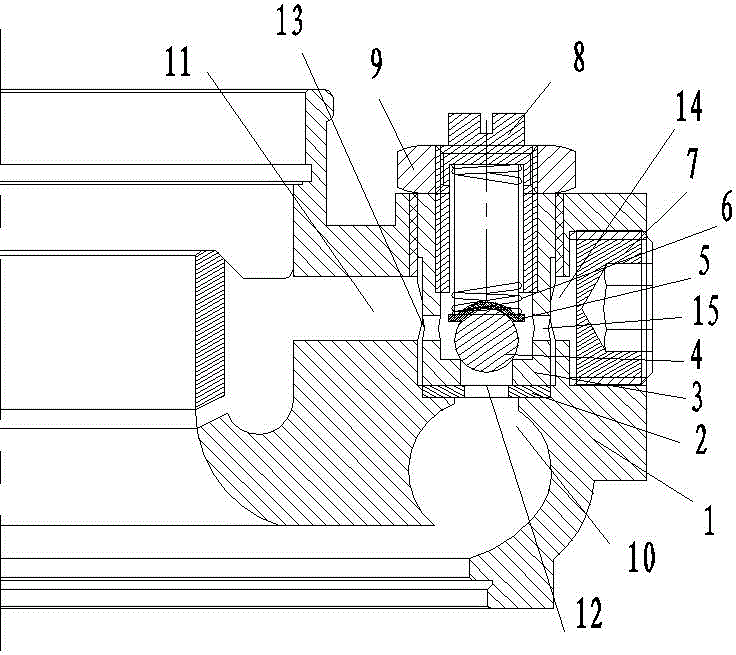

[0021] refer to figure 1 , a pressure-adjustable turbocharger regulator valve, which is installed on the casing of the compressor volute 1 of the turbocharger. The first pressure relief passage 10 communicates with the second pressure relief passage 11 connected to the air inlet of the compressor. The first pressure relief channel 10 and the second pressure relief channel 11 are integrated into a cylindrical depression at the edge of the compressor volute 1; the pressure stabilizing valve includes a pressure stabilizing valve housing 3, and the stabilizing The pressure valve housing 3 is a hollow cylinder with threads on the inner and outer surfaces, and is screwed into the cylindrical recess by the threads on the inner surface of the cylindrical recess at the edge of the compressor volute 1 . The center of the bottom end of the pressure stabilizing valve housing 3 is provided with a circular opening 12, and there is a sealing ring 2 between the bottom end of the pressure sta...

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is that the central axis of the pressure stabilizing valve housing 3 and the central axis of the compressor volute 1 in embodiment 2 are placed on the edge of the compressor volute perpendicular to each other.

[0025] Beneficial effects of the present invention:

[0026] A: The spring cushion 5 protects the steel ball 4 from the friction wear of the pneumatic spring 6 to maintain the sealing accuracy of the steel ball 4; the pressure stabilizing valve housing 3 can protect the compressor volute 1 from the pressure regulating valve plug 8 Frictional damage from frequent turning during adjustment.

[0027] B: The downward pressure on the floating valve 4 depends on the pressure of the pneumatic spring 6, and the pressure of the pneumatic spring 6 depends on the distance that the pressure regulating valve plug 8 is screwed into the pressure stabilizing valve housing 3, so it can be adjusted according to the specific wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com