Position controlling method of EOV (Electrically Operated Valve)

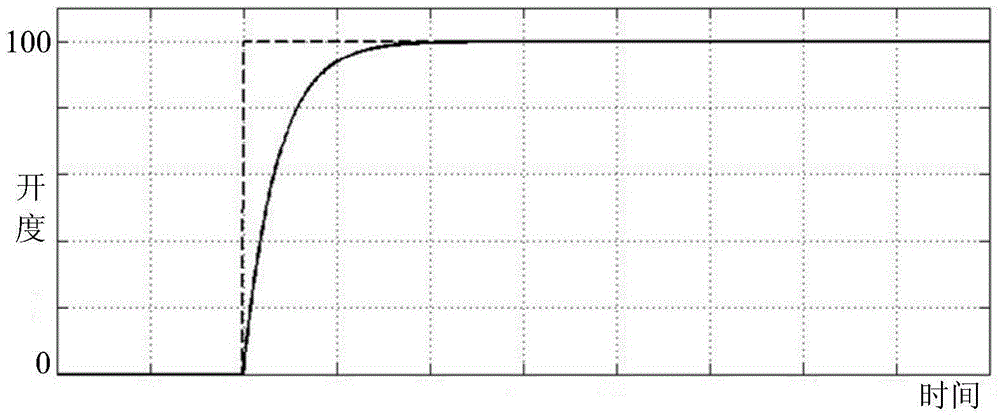

An electric valve and control method technology, applied in valve device, valve operation/release device, valve details, etc., can solve problems such as low reusability and complex valve opening, eliminate phenomena, improve valve response time, Eliminates the effect of valve overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

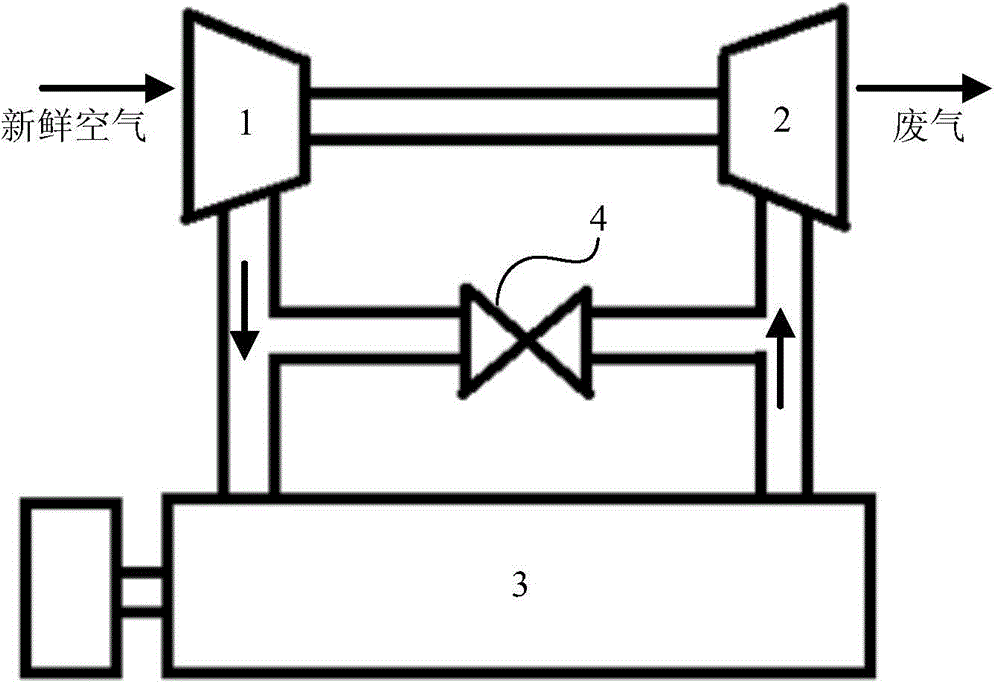

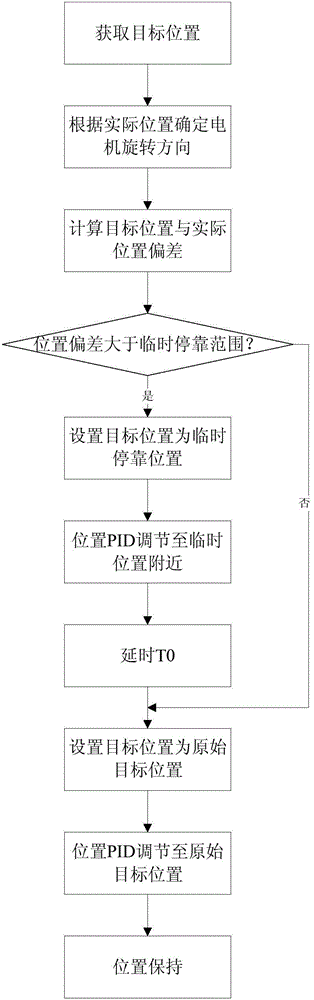

[0019] The position control method of the electric valve provided by the present invention is as follows: during the operation of the electric valve, the controller obtains the actual position signal, determines the rotation direction of the motor according to the actual position, and calculates the deviation between the current position and the actual position. When the position deviation is greater than the temporary stop range, the target position is set as the temporary stop position, and the proportional term, integral term and differential term of the motor PID regulation duty cycle are calculated. When the motor runs near the temporary target position, delay for a period of time. Then set the target position as the original target position, recalculate the position deviation, and then calculate the proportional term, integral term and differential term of the dut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com