A two-stage solar heat absorber

A technology for solar heat absorbers and heat absorbing areas, which is applied in the field of solar energy applications, can solve the problems of poor practicability of heat absorbers, insufficient consideration of Gaussian distribution characteristics of concentrated solar energy flow density, etc., and achieve good heat resistance and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

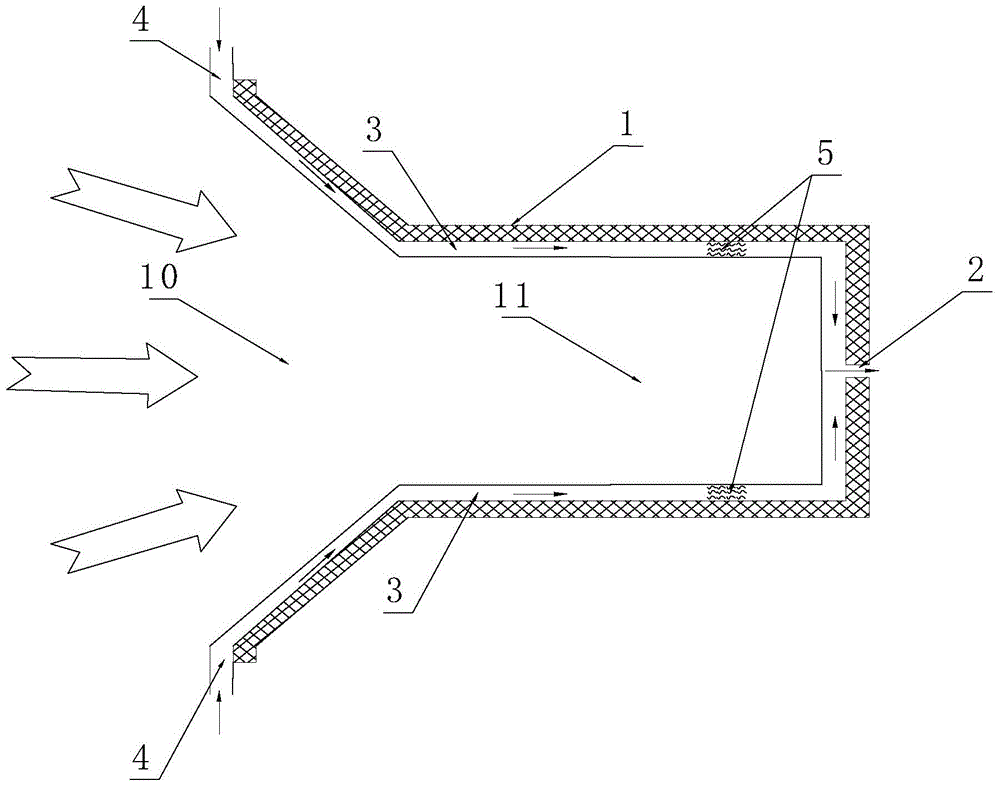

[0047] refer to figure 1 , the present invention provides a two-stage heat-absorbing solar heat absorber, comprising a cavity 1, the cavity is divided into a low-temperature heat-absorbing zone 10 and a high-temperature heat-absorbing zone 11, the high-temperature heat-absorbing zone 11 is a cylindrical shape with one end open, and the cavity The bottom end of the body 1 is provided with a working medium outlet 2; the low-temperature heat absorption area 10 is a truncated conical structure; the inner wall of the cavity 1 is provided with an interlayer channel 3 for accommodating the passage of the air working medium, and the interlayer channel 3 is located at the edge of the truncated conical structure. There is an air working medium inlet 4, and the interlayer channel 3 is located in a section of the high-temperature heat-absorbing area. A foam material 5 is arranged in a section of the channel to strengthen the heat exchange between the working medium and the high-temperature...

Embodiment 2

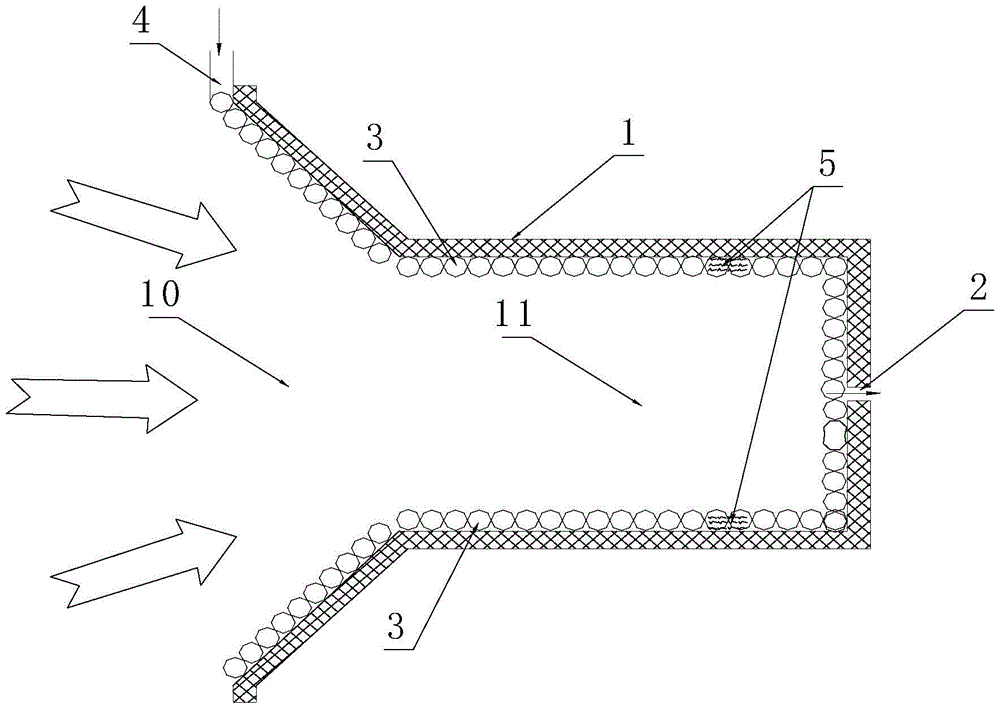

[0050] refer to figure 2 , the present invention provides a two-stage heat-absorbing solar heat absorber, comprising a cavity 1, the cavity is divided into a low-temperature heat-absorbing zone 10 and a high-temperature heat-absorbing zone 11, the high-temperature heat-absorbing zone 11 is a cylindrical shape with one end open, and the cavity The bottom end of the body 1 is provided with a working fluid outlet 2; the low-temperature heat absorption area 10 is a truncated conical structure; the inner wall of the cavity 1 is provided with an interlayer channel 3 for accommodating the passage of the air working medium, and the interlayer channel 3 is located at the edge of the truncated conical structure. There is an air working medium inlet 4, and the interlayer channel 3 is located in a section of the high-temperature heat-absorbing area. A foam material 5 is arranged in a section of the channel to strengthen the heat exchange between the working medium and the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com