Groove type solar heat collecting tube for high temperature

A trough solar energy and heat collecting tube technology is applied in the direction of solar heat collectors, solar heat collectors, and solar thermal energy using working fluid, which can solve the problems of increasing operating costs, increasing heat loss, and increasing operating heat loss, etc. Achieve the effect of reducing system operation heat loss, radiation heat transfer loss, and improving effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

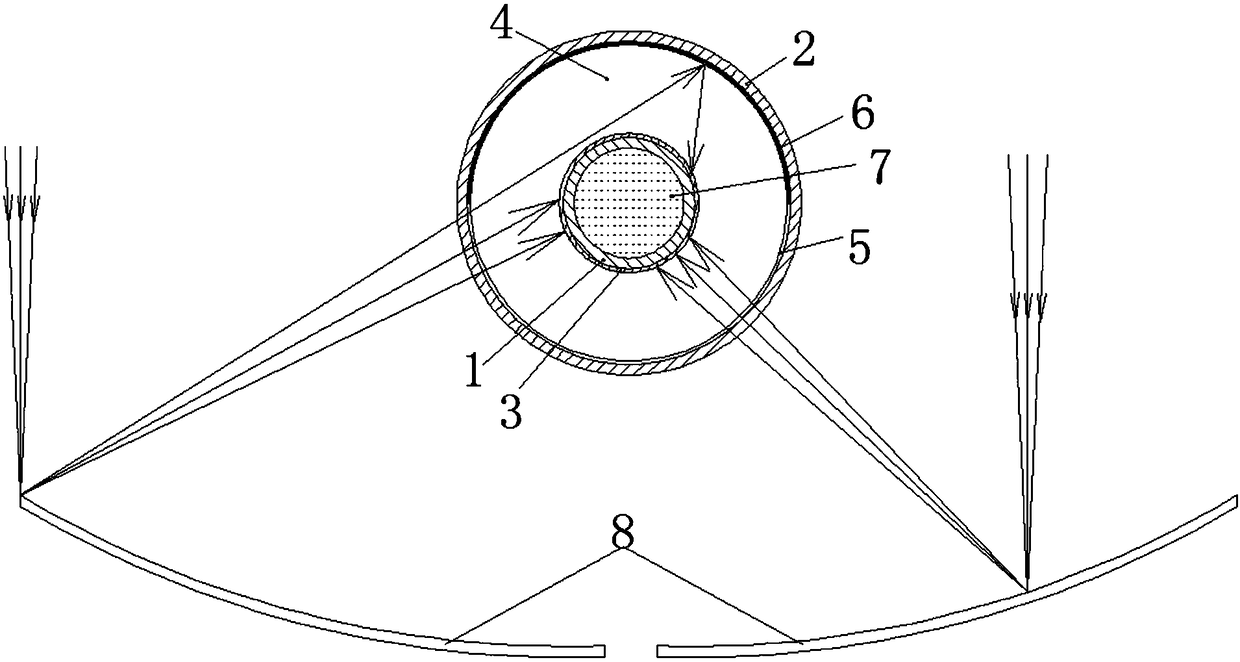

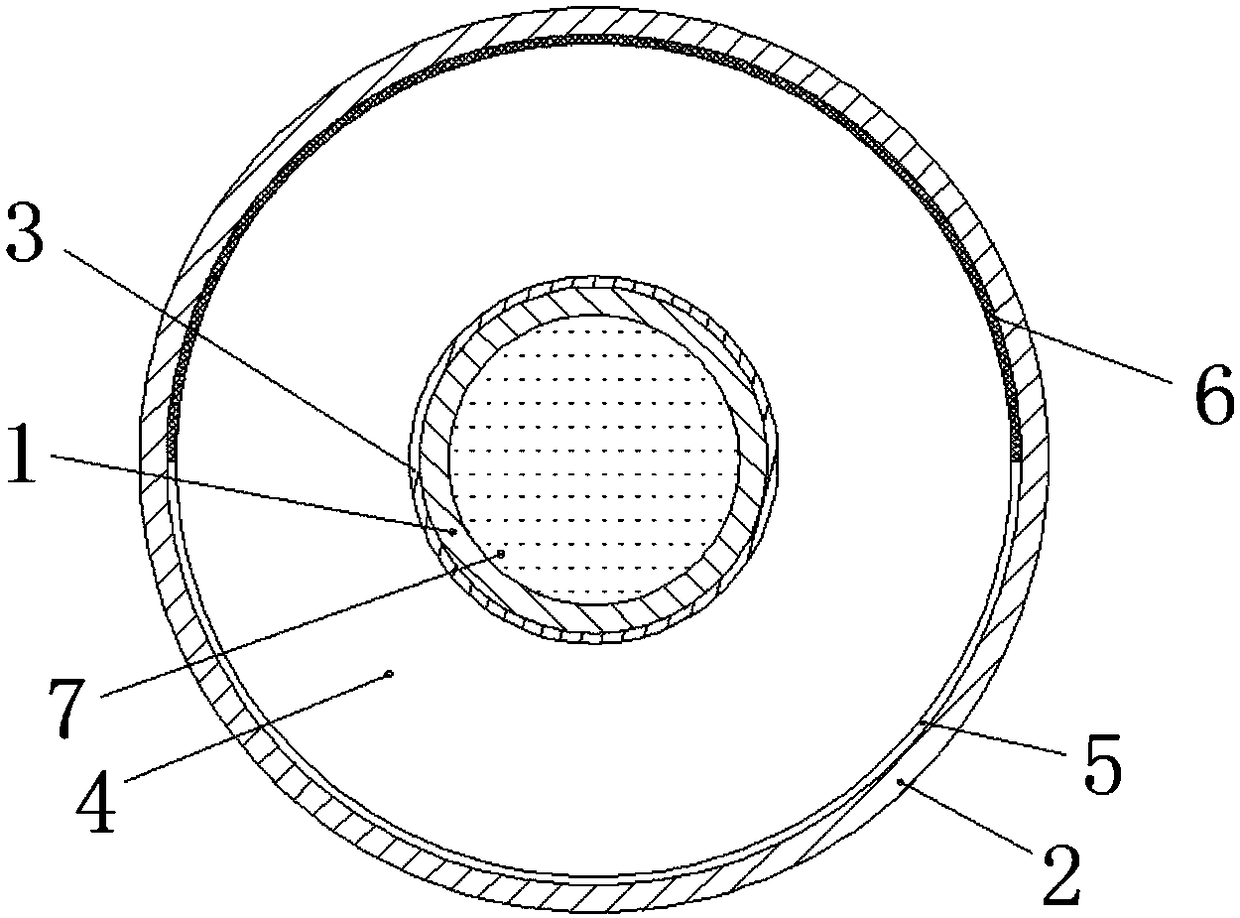

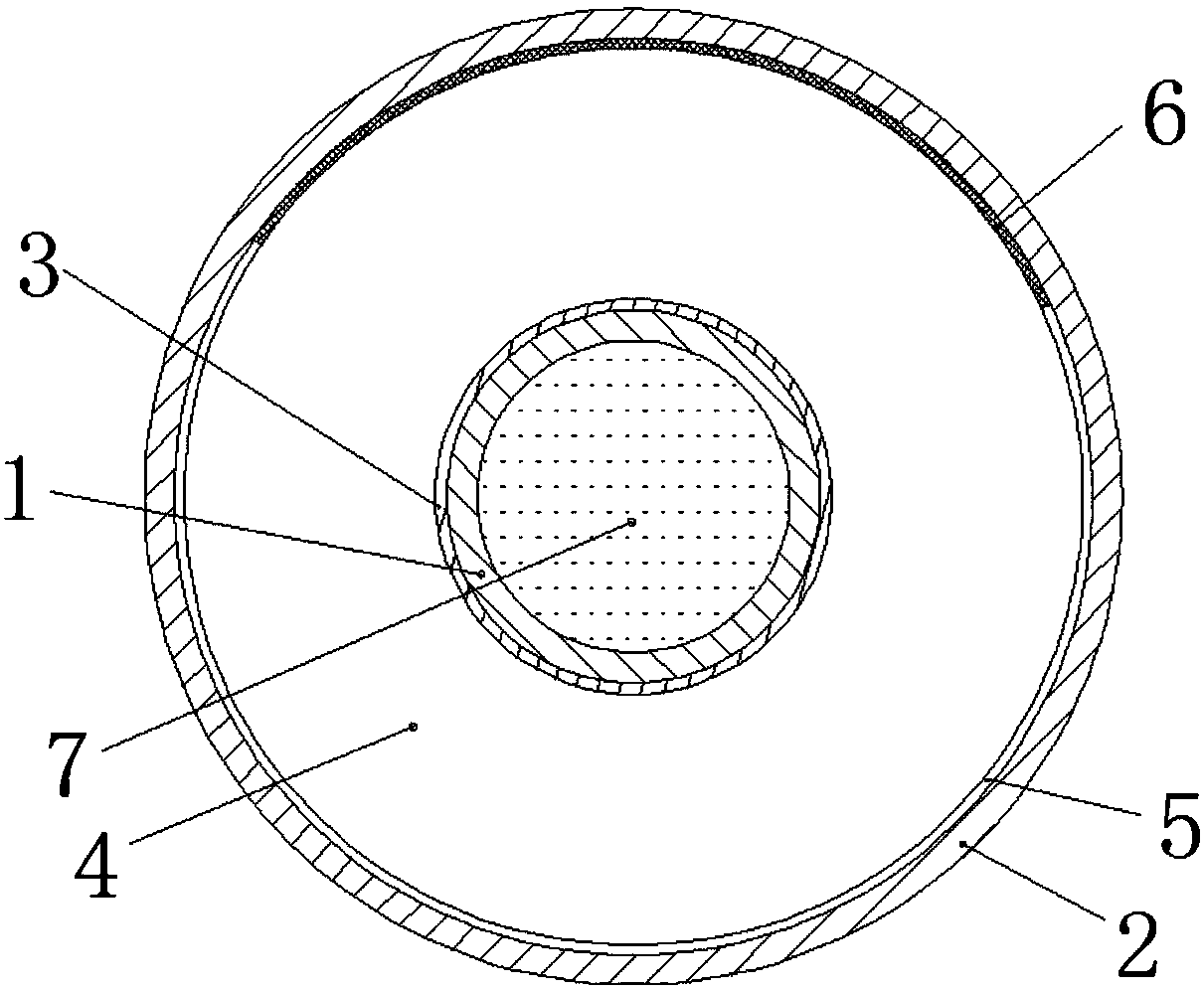

[0024] Embodiment 1 of the present invention is used for the trough type solar collector tube of high temperature as figure 1 and figure 2 As shown, it includes a glass outer tube 2 and a metal inner tube 1, the metal inner tube 1 has a high temperature resistant selective absorption coating 3, the glass outer tube 2 is coaxially sleeved outside the metal inner tube 1, and the glass outer tube 2 and the metal An annular vacuum closed space 4 is formed between the inner tubes 1 . The heat transfer working medium 7 in the metal inner tube 1 is high temperature molten salt. The selective absorbing coating 3 is made by magnetron sputtering equipment, and consists of four layers: an anti-reflective coating layer, a low-absorbing layer, a high-absorbing layer, and an infrared high-reflecting layer from outside to inside. The selective absorbing coating 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com