Solar water-working-medium cavity-type heat absorber

A solar energy and heat sink technology, applied in the field of concentrating solar thermal power generation devices, can solve the problems of uneven heat flow density and large heat loss, and achieve the effects of solving heat loss, increasing heat absorption, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail: this embodiment is carried out under the premise of technical solution of the present invention, has provided detailed implementation mode and process, but protection scope of the present invention is not limited to following implementation example.

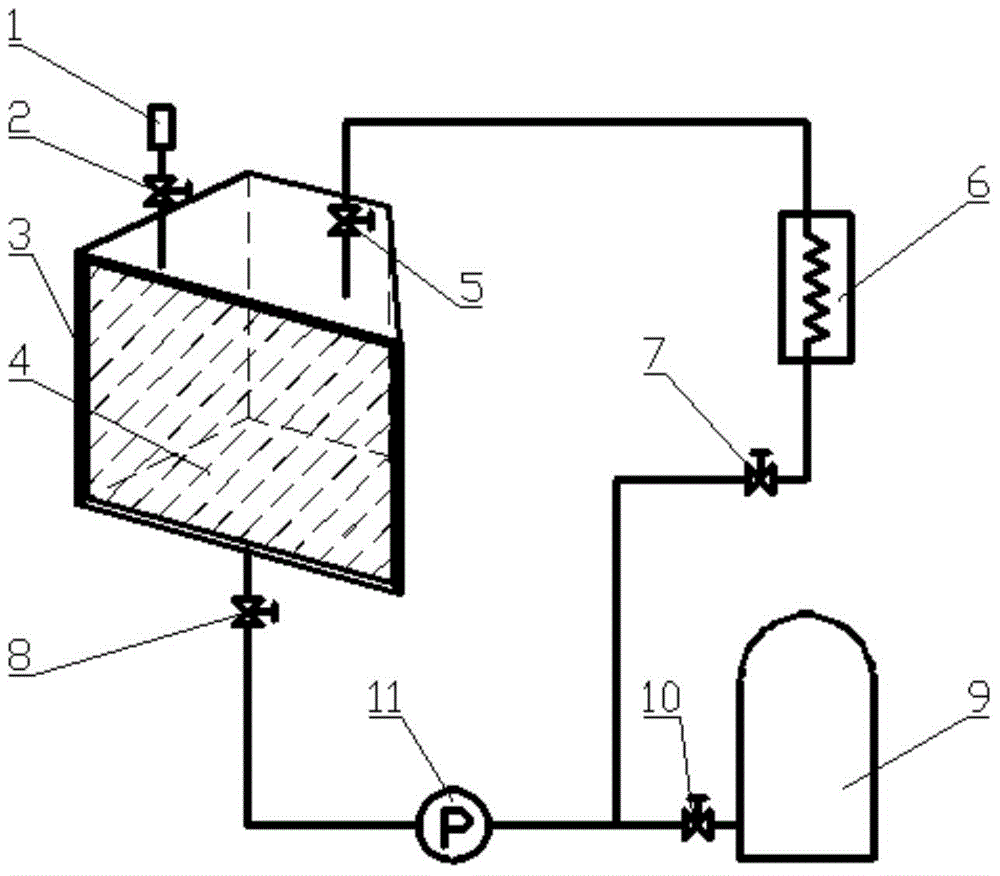

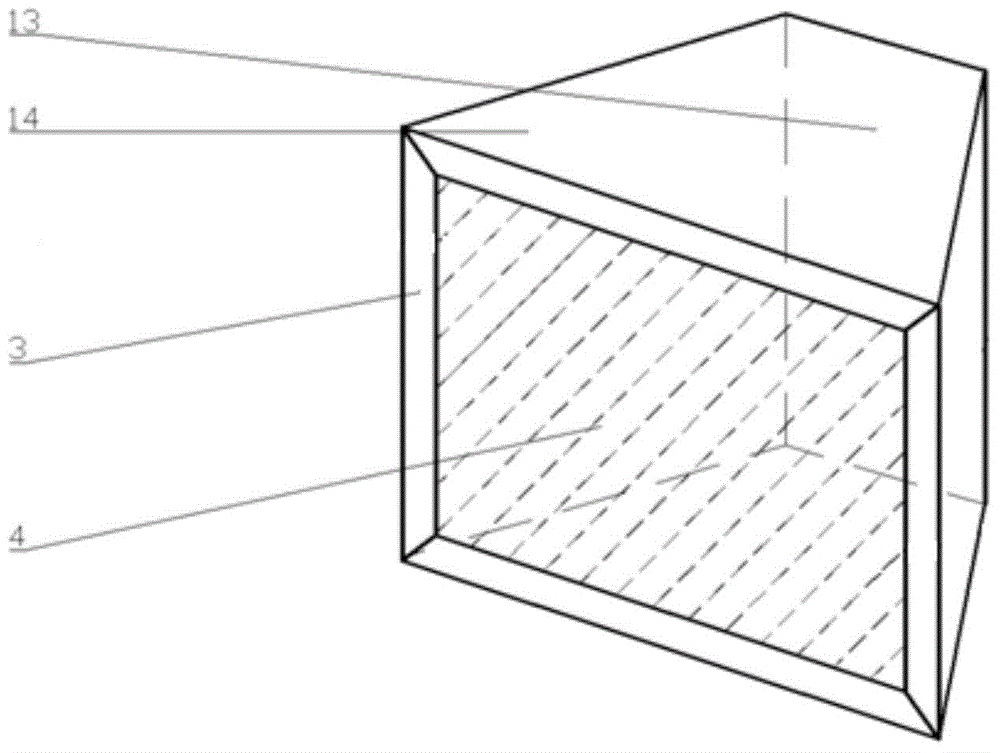

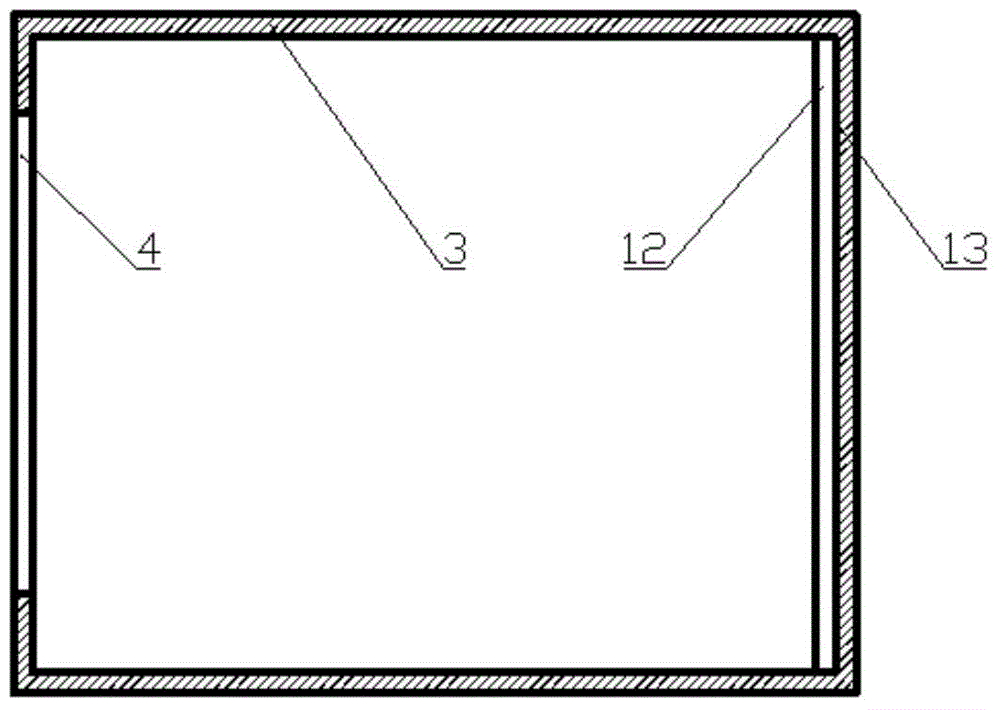

[0024] see figure 1 and figure 2 , an improved solar hydraulic mass cavity heat absorber of the present invention, comprising an air supply unit, a heat exchange unit and a cavity 3;

[0025] The gas supply unit includes CO with a certain pressure 2 Gas tank 9, CO 2 A first valve 10 is provided at the exhaust port of the gas storage tank 9, and the CO 2 A gas pump 11 is also provided on the pipeline connecting the gas storage tank 9 and the cavity 3 , and a second valve 8 is provided at the air inlet of the cavity 3 . On the top of the cavity 3, there is an air discharge valve 2 and a CO 2 Gas outlet valve 5. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com