Device and assembling method for eliminating additional load of torque sensor

A torque sensor and additional load technology, which is applied in the direction of measuring devices, instruments, torque measurement, etc., can solve the problems of increasing the difficulty of processing and assembling the transmission system, the sensor torque value exceeds the limit, and the system cannot work normally, so as to improve the measurement The effect of precision and reliability in use, elimination of influence, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The core idea adopted by the device for eliminating the additional load of the torque sensor in the present invention is: connect the output shafts at both ends of the torque sensor with a conversion shaft first, and then connect the conversion shaft with the power source and the driven device, the two ends of the torque sensor Converts axis coaxiality settings.

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

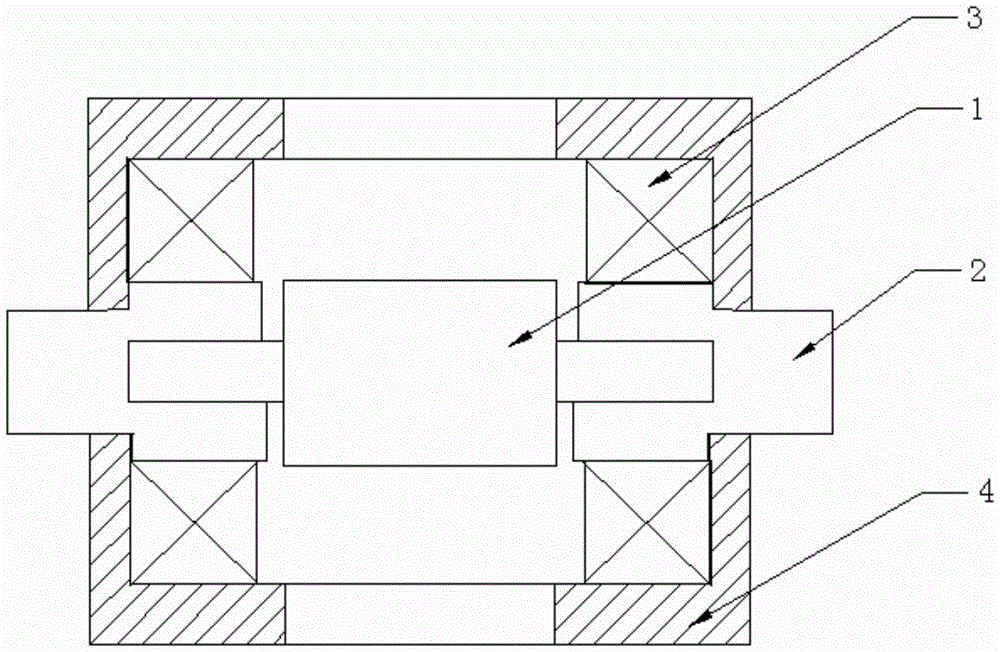

[0021] A device for eliminating additional loads on torque transducers such as figure 1 As shown, including torque sensor 1, conversion shaft 2, bearing 3 and housing 4,

[0022] The output shafts at both ends of the torque sensor 1 are respectively connected with a coaxial conversion shaft 2, and the conversion shaft 2 protects the torque sensor 1 from additional loads and transmits torque at the same time;

[0023] The conversion shaft 2 is in interference fit with the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com