Shear test fixture

A shear test and fixture technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of non-pure shear damage, easy to shake, complex shape, etc., to achieve the effect of ensuring slip and increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

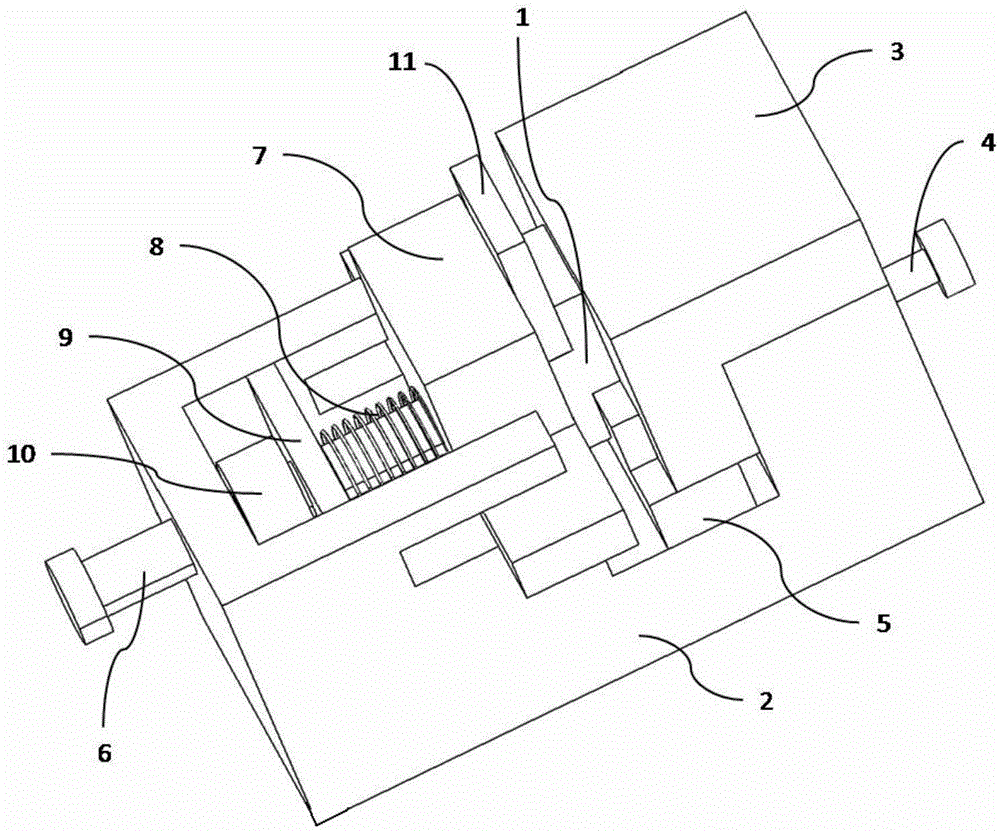

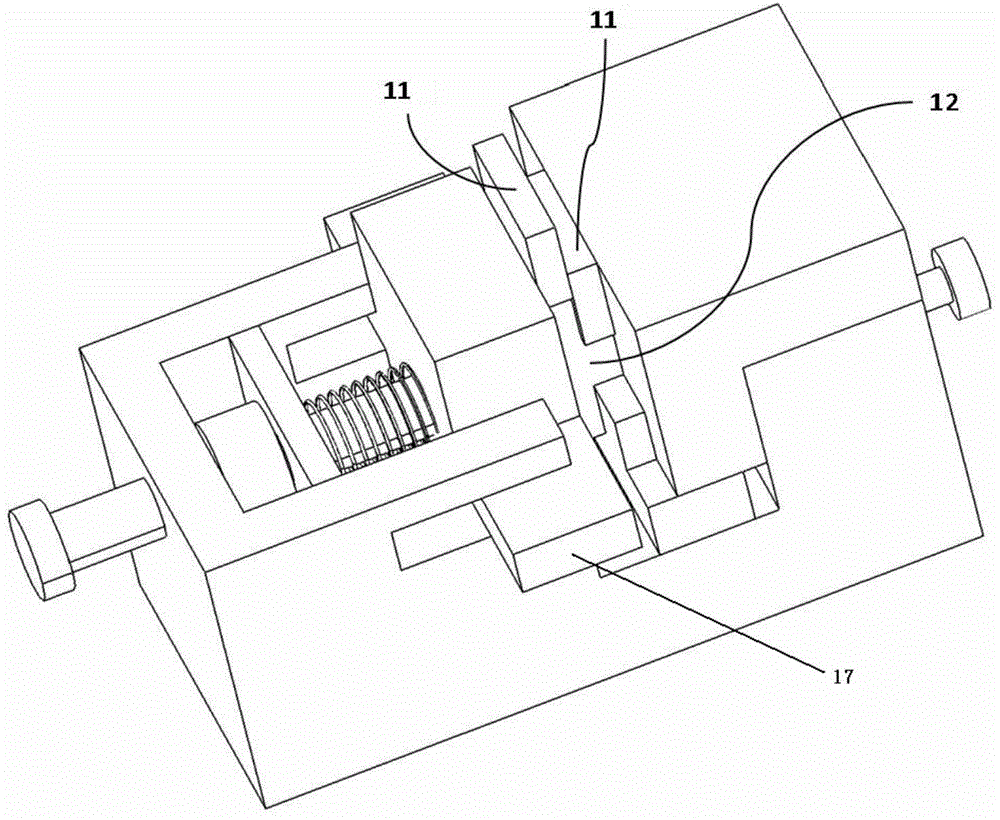

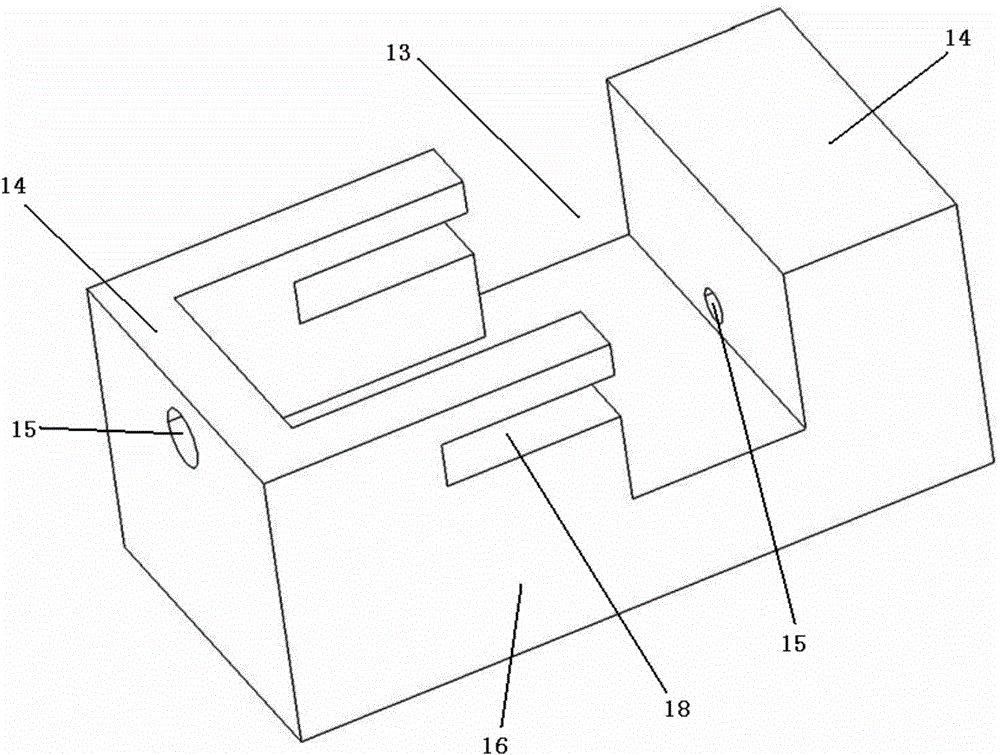

[0019] See attached Figure 1~5 As shown, this kind of shear test fixture is characterized in that: the fixture includes a base platform 2, and a concave cavity 13 is processed in the middle part of the base platform 2, and the bottom of the cavity 13 is placed two for The lower slider 5 and the positioning slider 7 for clamping the sample are respectively pushed by the first positioning rod 4 and the second positioning rod 6, and the first positioning rod 4 and the second positioning rod 6 Respectively pass through the holes 15 on the two end faces 14 of the cavity 13, the holes 15 are threaded holes, the first positioning rod 4 and the second positioning rod 6 are threaded rods, and the two are rotated by threaded connection, the upper part of the lower slider 5 A fixed block 3 fixedly connected to the base platform 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com