A method for measuring bulk density and void ratio of coarse aggregate

A technology of bulk density and measurement method, which is applied in the field of measurement of bulk density and interstitial ratio of coarse aggregate, can solve the problems of difficult identification and unification, and achieve the effects of easy unification of standards, stable data, and improved accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

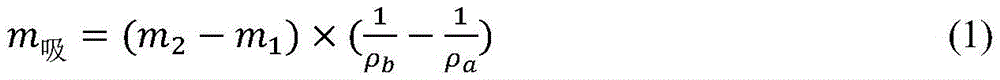

Method used

Image

Examples

Embodiment 1

[0091] The assay method of the present invention has obtained good experimental verification. The bulk density of the coarse aggregate and the skeletal void ratio of the coarse aggregate in the compacted state are measured by the method in the current specification and the method of the present invention respectively.

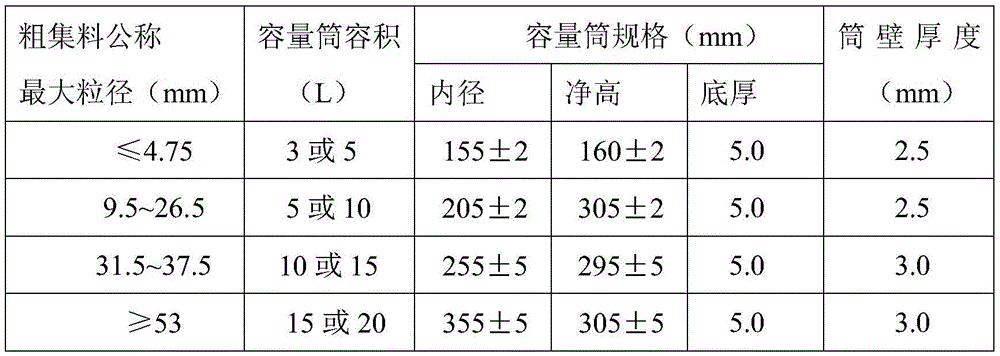

[0092] The instruments and materials needed in this embodiment include: (1) balance (sensitivity is not greater than 0.1% of weighing); (2) 5L capacity cylinder; (3) flat-headed shovel; (4) oven (capable of temperature control 105 ℃ ± 5°C); (5) Vibrating table (frequency 3000 times / min±200 times / min, amplitude under load is 0.35mm, amplitude under no load is 0.5mm); (6) Tamping rod (diameter 16mm, length 600mm steel rod with a round head at one end); (7) 1000mL beaker; (8) basalt as coarse aggregate.

[0093] The gross bulk density and apparent density of the coarse aggregate were measured according to the method in the T0308 test procedure 05 of "JTGE42-2005 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com