Sheet workpiece phased array ultrasonic guided wave imaging detection system and detection method thereof

An ultrasonic guided wave and imaging detection technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, and can solve the problem of inability to observe scanning images at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

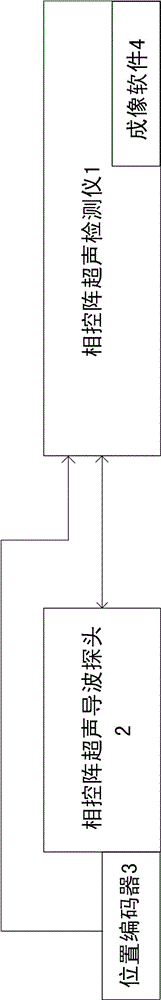

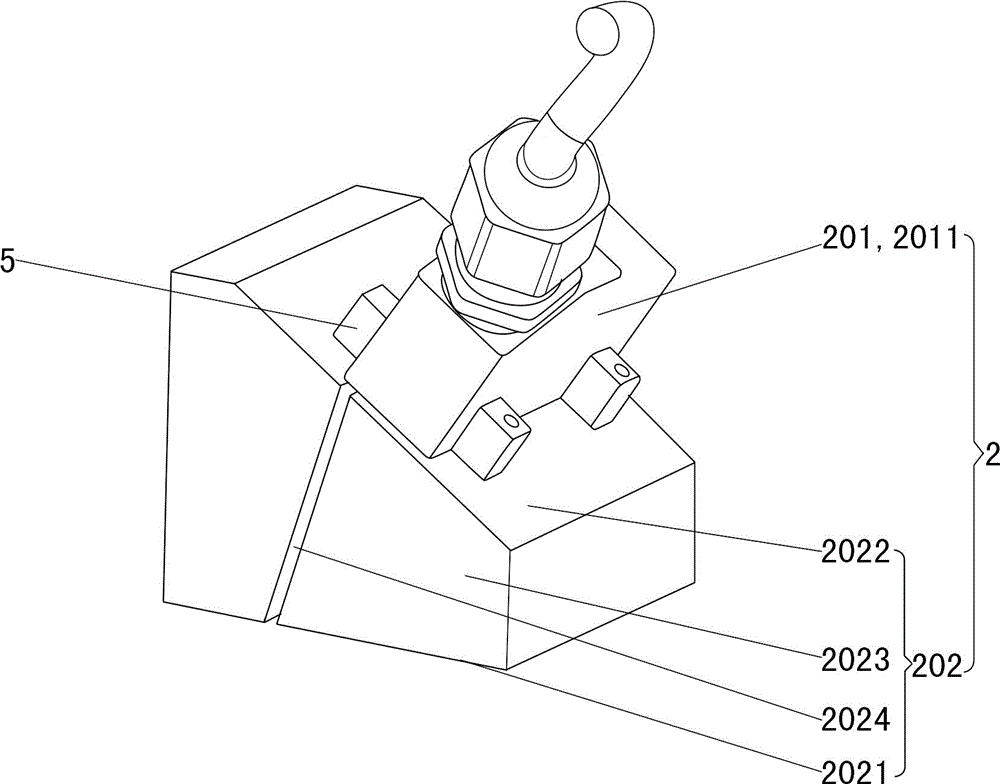

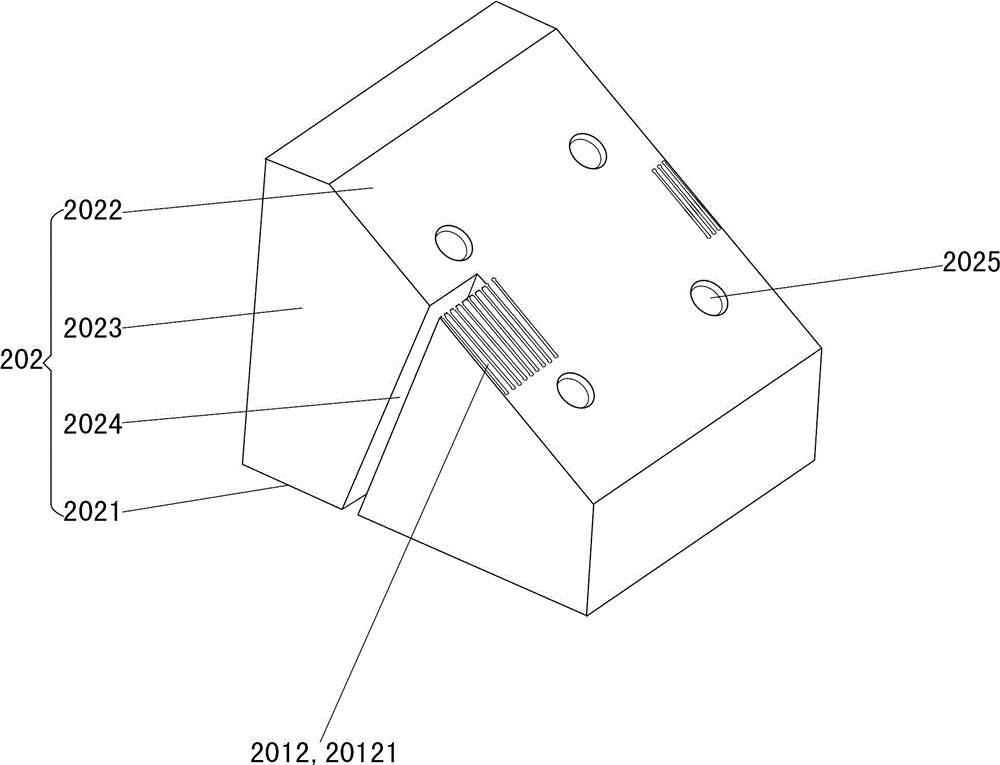

[0035] Such as Figure 1 to Figure 5 As shown, this thin plate workpiece phased array ultrasonic guided wave imaging detection system includes a phased array ultrasonic detector 1, a phased array ultrasonic guided wave probe 2, a position encoder 3 and imaging software 4; the position encoder 3 is installed in On the phased array ultrasonic guided wave probe 2, the phased array ultrasonic guided wave probe 2 and the position encoder 3 are electrically connected to the phased array ultrasonic detector 1; the imaging software 4 is installed in the phased array ultrasonic detector 1; The controlled array ultrasonic guided wave probe 2 includes a phased array ultrasonic probe 201 and an ultrasonic guided wave wedge 202; the ultrasonic guided wave wedge 202 has a bottom surface 2021, an inclined surface 2022 opposite to the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com