Automated relay finished product test system

A test system and relay technology, applied in the direction of circuit breaker testing, etc., can solve the problems of high labor cost, increased enterprise risk, and susceptibility to occupational diseases, etc., and achieve the effect of simple structure, reduced labor cost, and increased cost and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

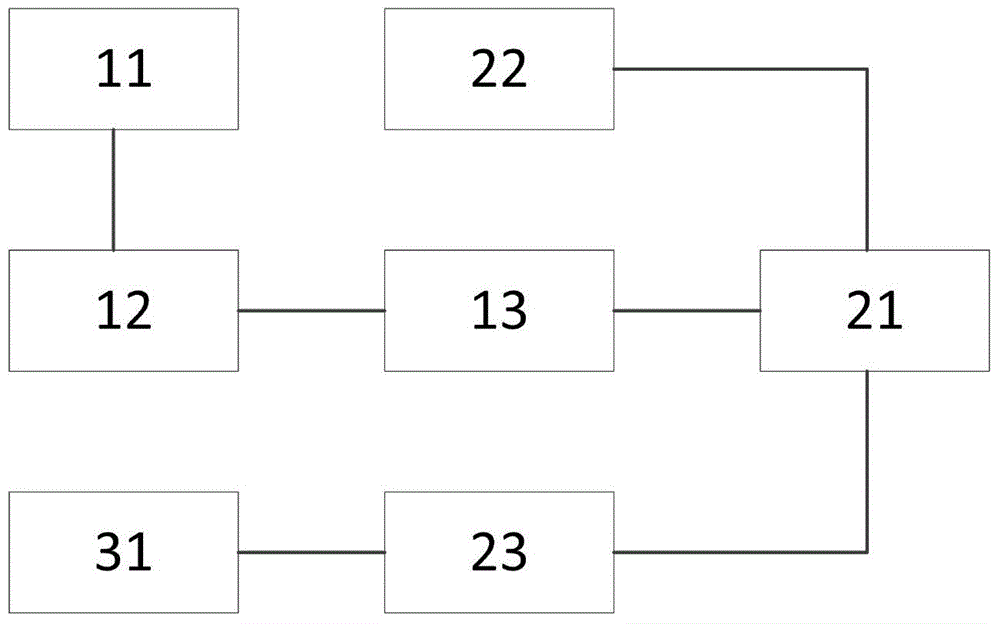

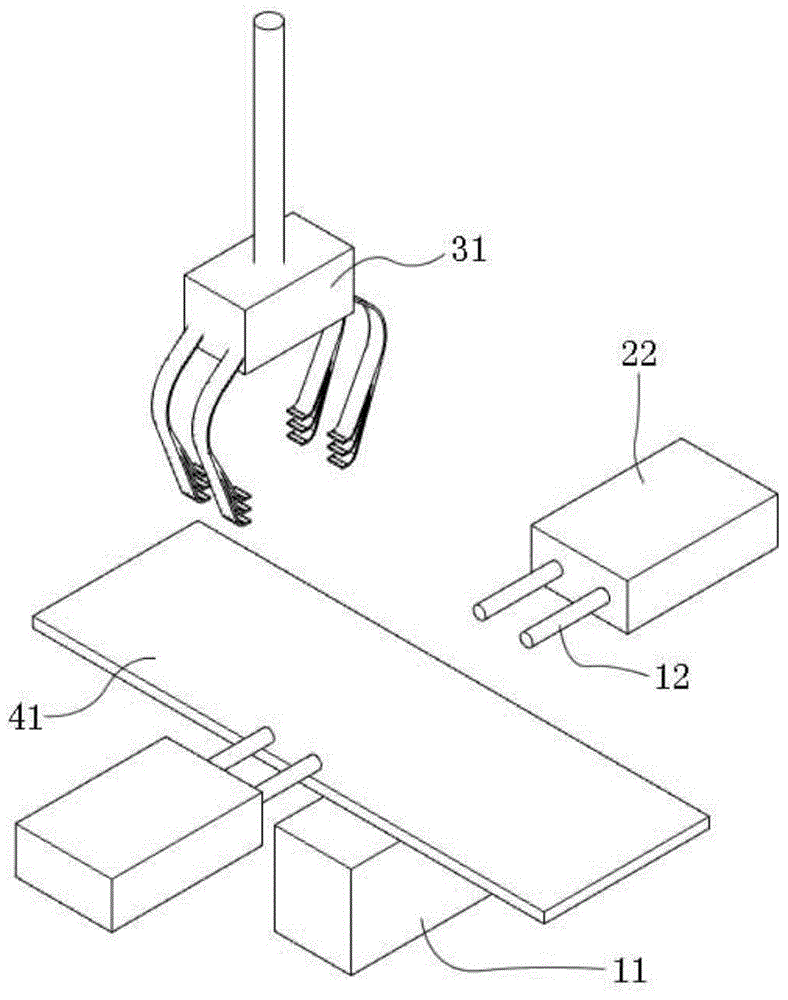

[0017] Such as figure 1 , figure 2 A kind of automated relay finished product testing system shown, comprises test feeler bar 12, pusher 22, mechanical claw 31, conveyer belt 41; And pushing device 22 is arranged on the side top of conveyor belt 41; Described mechanical claw 31 is arranged on the top of conveyor belt 41; Test contact bar 12 circuit is connected with test circuit 13, and mechanical claw 31 is connected with action circuit 23, and pushing device 22, test The circuit 13 and the action circuit 23 are connected to the control system 21 in parallel.

[0018] The test probe 12 is also connected to the voltage output of the transformer 11, and the output voltage of the transformer 11 is variable.

[0019] The number of the test probes 12 is four, and each group of two is oppositely arranged on both sides of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com