Hydrostatic rotary table kinematic error modeling and computing method

A technology of motion error and static pressure turntable, which is applied in calculation, special data processing applications, instruments, etc., can solve the problem of insufficient processing error of turntable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention implements a static pressure turntable motion error modeling and calculation method that considers machining contour errors. The implementation of the present invention will be specifically described below in conjunction with the accompanying drawings.

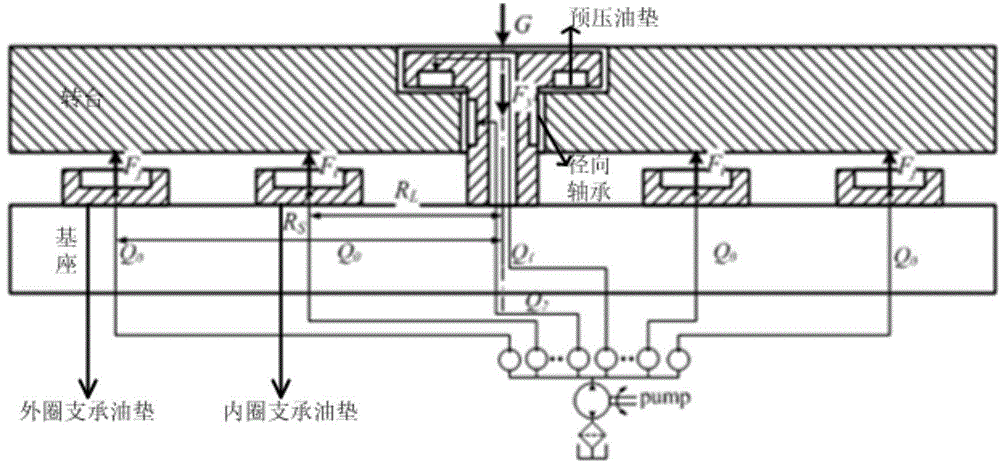

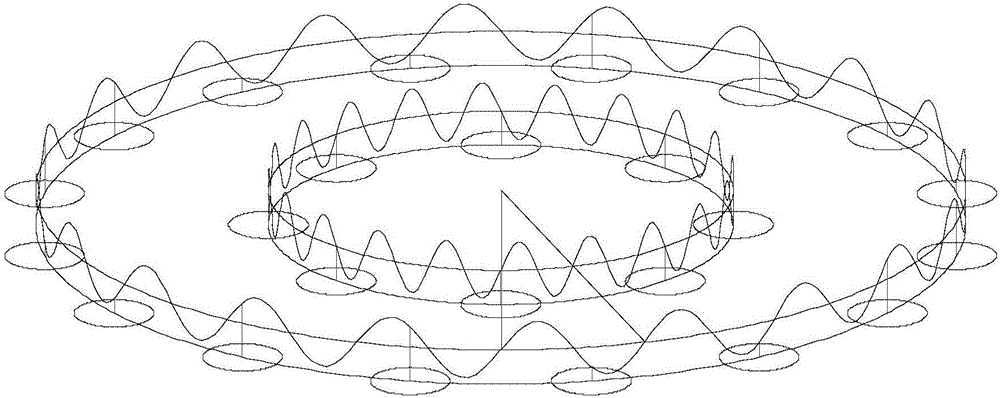

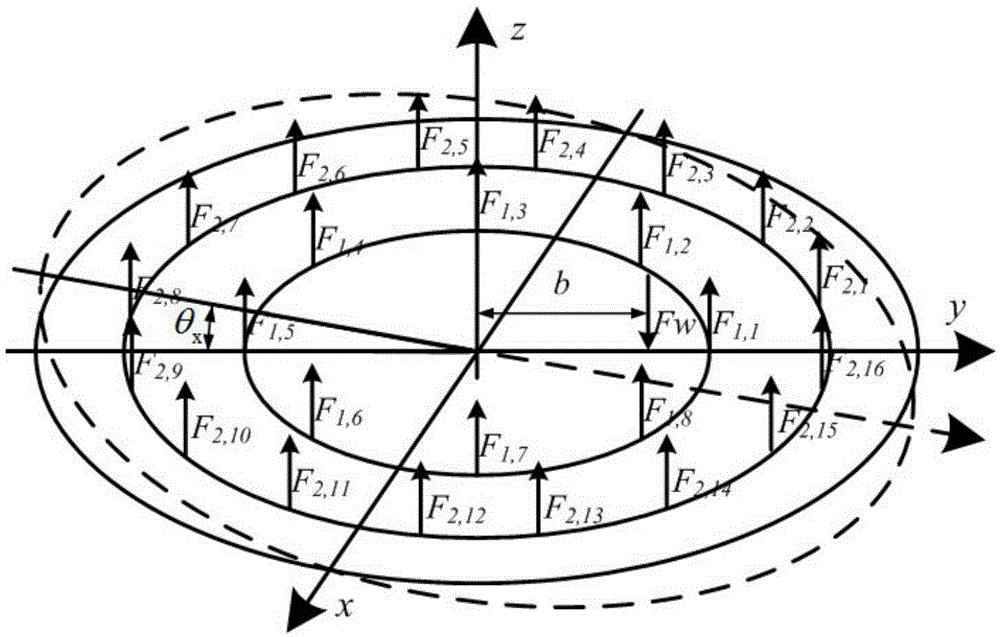

[0022] figure 1 It is a schematic diagram of the structure of the static pressure turntable. The turntable is composed of a turntable, a base, a supporting oil pad, a pre-pressing oil pad, and a radial bearing. The supporting oil pad is a double-circle circular oil pad, and the pre-pressing oil pad is an annular pre-pressing oil pad. Pad, a radial bearing is installed in the center of the turntable. The oil pads of the turntable are supplied by quantitative pumps. Due to processing, the guide rail surface of the turntable will be uneven, and the sine function is used to describe the fluctuation of the guide rail surface of the turntable equivalently. The self-weight of the turntable is G, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com