Power system for hump gear reducers

A technology of hump reducer and power system, which is applied in the direction of power network operating system integration, emergency power supply arrangement, information technology support system, etc., can solve the problem of hump reducer not working, reduce the scope of fault judgment and avoid out of control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

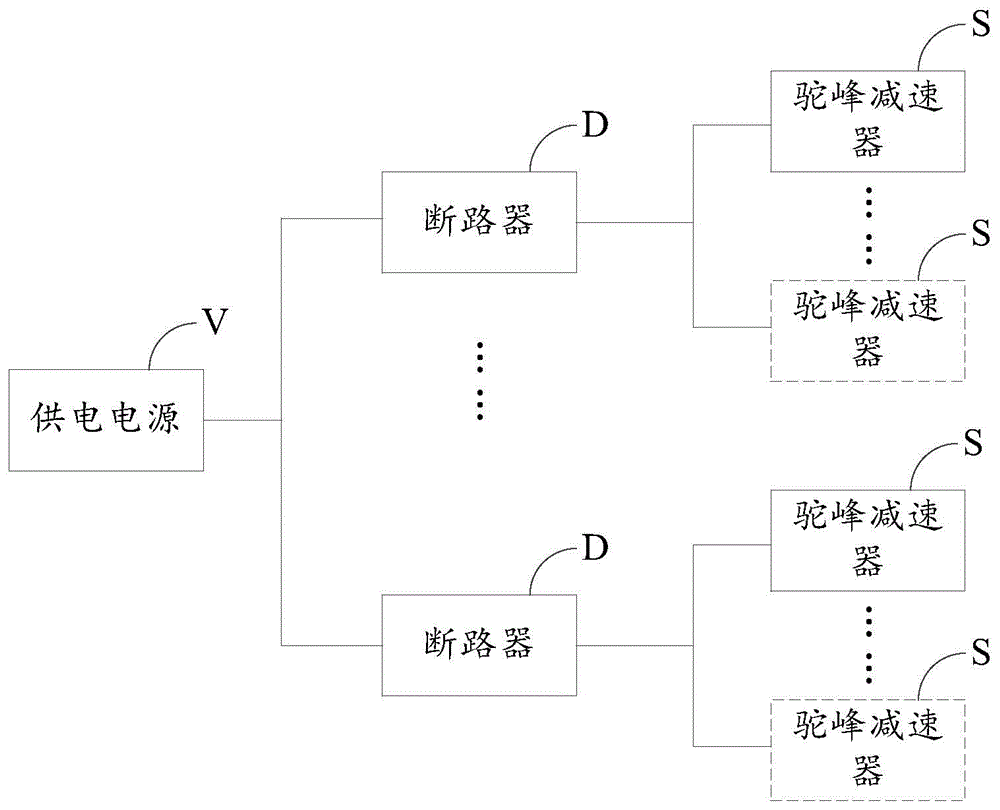

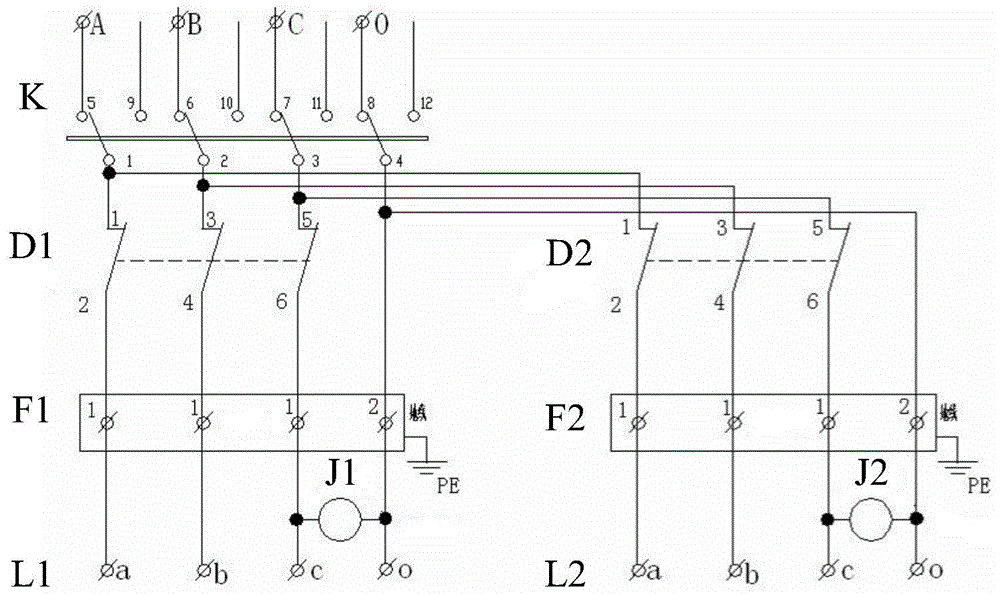

[0025] In order to solve the technical problem in the prior art that all hump reducers in the system cannot work when the AC power fails, the embodiment of the present invention provides a power supply system for hump reducers. After being divided into multiple sub-power supplies, use the multi-channel sub-power supply to supply power to multiple hump reducers. When the sub-power supply fails or fails, only the circuit where the sub-power supply is located is out of control, effectively avoiding the loss of control of the entire hump reducer. At the same time, the scope of fault judgment is also reduced, and hierarchical control can be realized, the peak value can be effectively staggered, and power transmission can be realized step by step.

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com