Locomotive transplanter

A transplanting machine, mobile technology, applied in the direction of transplanting machinery, planting methods, plant protection covers, etc., can solve the problems of time-consuming and laborious, affecting the growth of seedlings, affecting the efficiency of transplanting work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

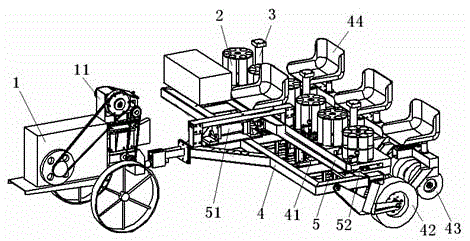

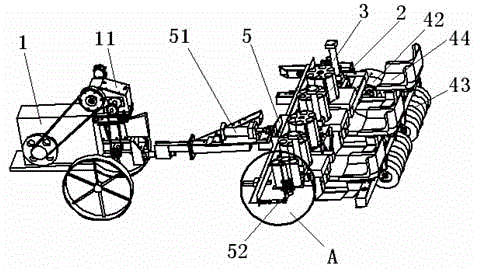

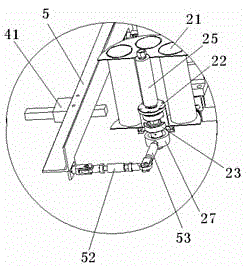

[0029] Embodiment 1: as Figure 1-8 Shown, a kind of motorized transplanting machine, comprises power tractor 1, the suspension frame 4 of the band walking wheel 42 that is connected with power traction machine 1 by hook movably, is installed in the throwing seedling mechanism 2 on the suspension frame 4 and sits. Chair 44, seedling planting mechanism 3 below the seedling throwing mechanism 2, soil pressing mechanism 43 below the seat 44, film pressing mechanism 6 next to the seedling planting mechanism 3; the seedling throwing mechanism 2 is connected to the power driver I through the connection assembly The seedling planting mechanism 3 is connected with the power driver II through the lifting assembly, and the connection assembly includes a sliding rod 5 placed on the slider 41 in the suspension frame 4 and connected with the power driver I, and a crank connection connected with the sliding rod 5. Rod 52, the rocking handle 53 that links to each other with crank connecting ...

Embodiment 2

[0030] Embodiment 2: as Figure 1-8 Shown, a kind of motorized transplanting machine, comprises power tractor 1, the suspension frame 4 of the band walking wheel 42 that is connected with power traction machine 1 by hook movably, is installed in the throwing seedling mechanism 2 on the suspension frame 4 and sits. Chair 44, seedling planting mechanism 3 below the seedling throwing mechanism 2, soil pressing mechanism 43 below the seat 44, film pressing mechanism 6 next to the seedling planting mechanism 3; the seedling throwing mechanism 2 is connected to the power driver I through the connection assembly The seedling planting mechanism 3 is connected with the power driver II through the lifting assembly, and the connection assembly includes a sliding rod 5 placed on the slider 41 in the suspension frame 4 and connected with the power driver I, and a crank connection connected with the sliding rod 5. Rod 52, the rocking handle 53 that links to each other with crank connecting ...

Embodiment 3

[0032] Embodiment 3: as Figure 1-8Shown, a kind of motorized transplanting machine, comprises power tractor 1, the suspension frame 4 of the band walking wheel 42 that is connected with power traction machine 1 by hook movably, is installed in the throwing seedling mechanism 2 on the suspension frame 4 and sits. Chair 44, seedling planting mechanism 3 below the seedling throwing mechanism 2, soil pressing mechanism 43 below the seat 44, film pressing mechanism 6 next to the seedling planting mechanism 3; the seedling throwing mechanism 2 is connected to the power driver I through the connection assembly The seedling planting mechanism 3 is connected with the power driver II through the lifting assembly, and the connection assembly includes a sliding rod 5 placed on the slider 41 in the suspension frame 4 and connected with the power driver I, and a crank connection connected with the sliding rod 5. Rod 52, the rocking handle 53 that links to each other with crank connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com