Manufacturing method of fully-reflective safety helmet

A manufacturing method and a technology of total reflection, applied in the field of reflection, can solve the problems that the quality does not meet the requirements, the reflective strip is easy to fall off, and the warning effect is not large, and achieves the effects of high manufacturing efficiency, no reflective dead angle, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

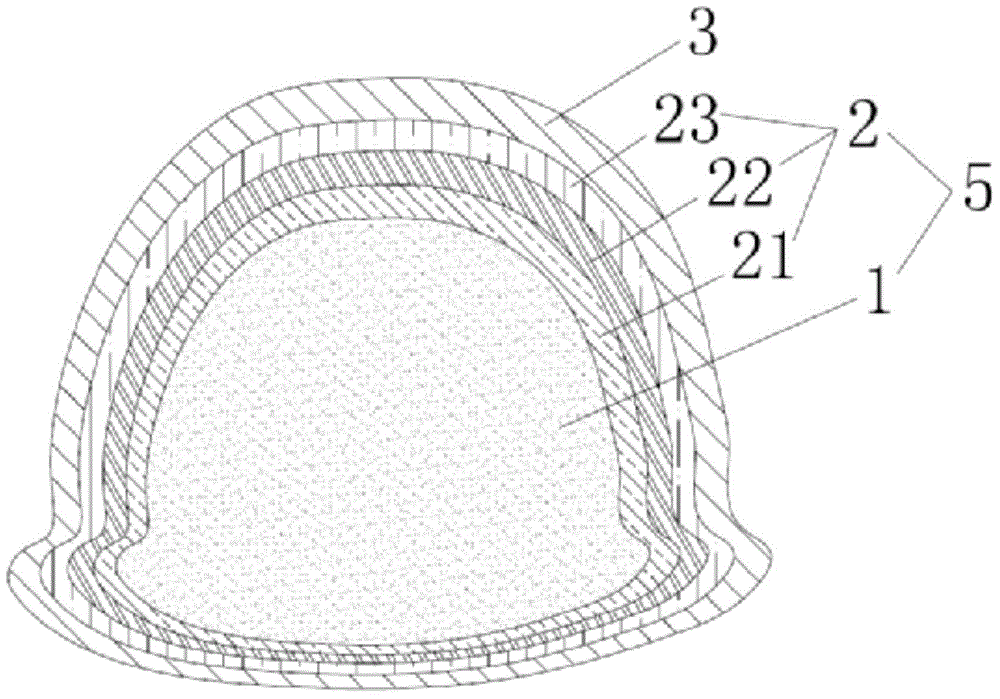

[0025] Embodiment 1: According to figure 1 Shown, a kind of manufacture method of full-reflection safety helmet comprises the following steps:

[0026] a) Prepare the safety helmet 1 after film molding and the fully reflective PET film 2 after blister molding;

[0027] Wherein the full-reflective PET film 2 is made of a transparent low-density PET film 21 as a base material, prepares a reflective layer 23 coated with a white hot-melt layer 22, and heats the reflective layer 23 by using a roller-type hot stamping machine or a flat press. made on a substrate;

[0028] b) Fix the prepared full-reflective PET film 2 to the helmet 1 through a blister machine to form a full-reflective helmet 5; the pressure range during the blistering process is 1kgf-3kgf, and the time range is 10s-20s , the temperature range is 180°C-200°C;

[0029] c) Prepare the PET color film 3 formed by blistering, and fix the PET color film 3 to the full-reflective safety helmet 5 through a blister machine ...

Embodiment 2

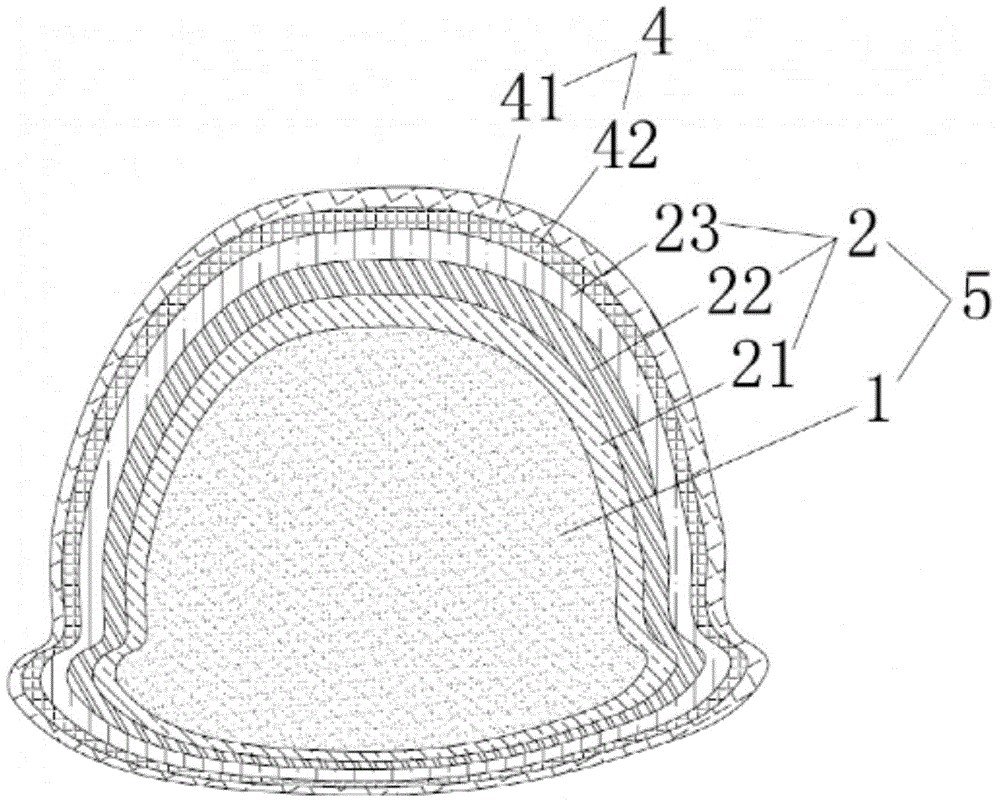

[0035] Embodiment 2: According to figure 2 Shown, a kind of manufacture method of full-reflection safety helmet comprises the following steps:

[0036] a) Prepare the safety helmet 1 after film molding and the fully reflective PET film 2 after blister molding;

[0037] Wherein the full-reflective PET film 2 is made of a transparent low-density PET film 21 as a base material, prepares a reflective layer 23 coated with a white hot-melt layer 22, and heats the reflective layer 23 by using a roller-type hot stamping machine or a flat press. made on a substrate;

[0038] b) Fix the prepared full-reflective PET film 2 to the helmet 1 through a blister machine to form a full-reflective helmet 5; the pressure range during the blistering process is 1kgf-3kgf, and the time range is 10s-20s , the temperature range is 180°C-200°C;

[0039] c) Prepare the low-density PET film 4 with the pattern printed on it, and fix the low-density PET film 4 with the pattern printed on it to the full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com