Patents

Literature

31results about How to "Reliable manufacturing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave multi-chip packaging structure using silicon through hole and manufacture method thereof

ActiveCN102723306AReduce lossIncrease packing densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSystem in package

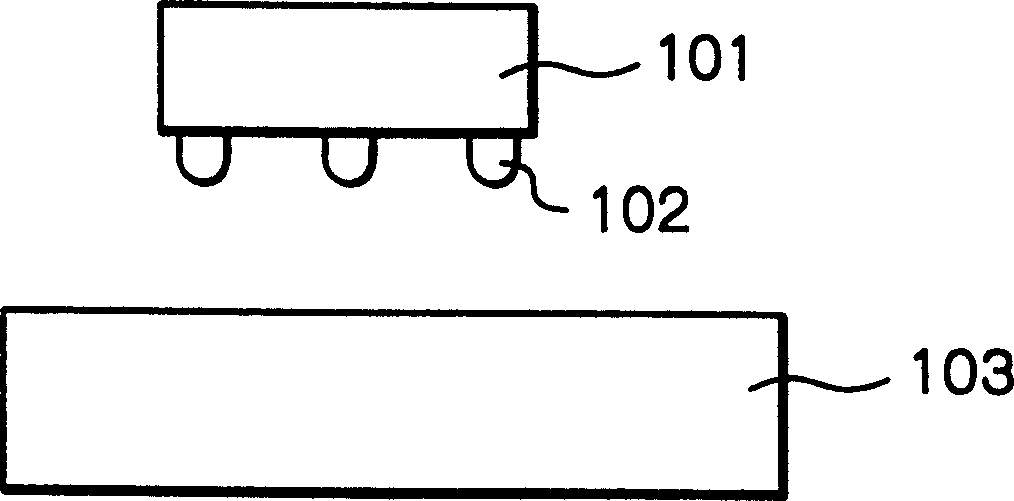

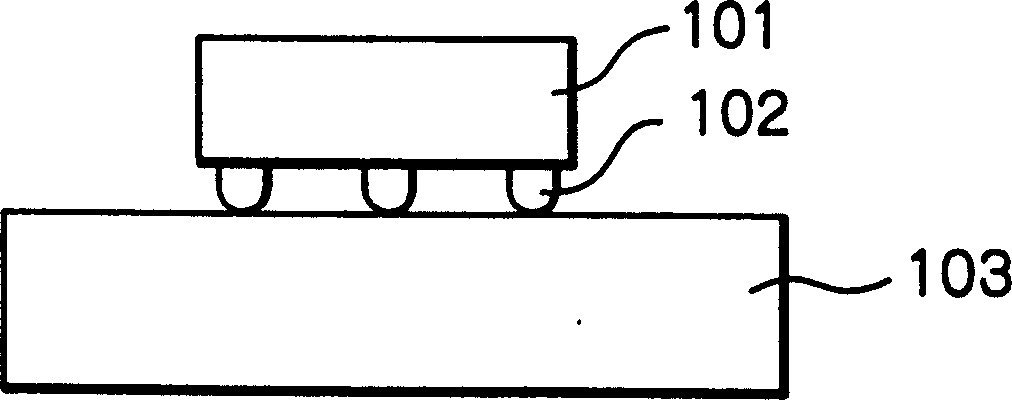

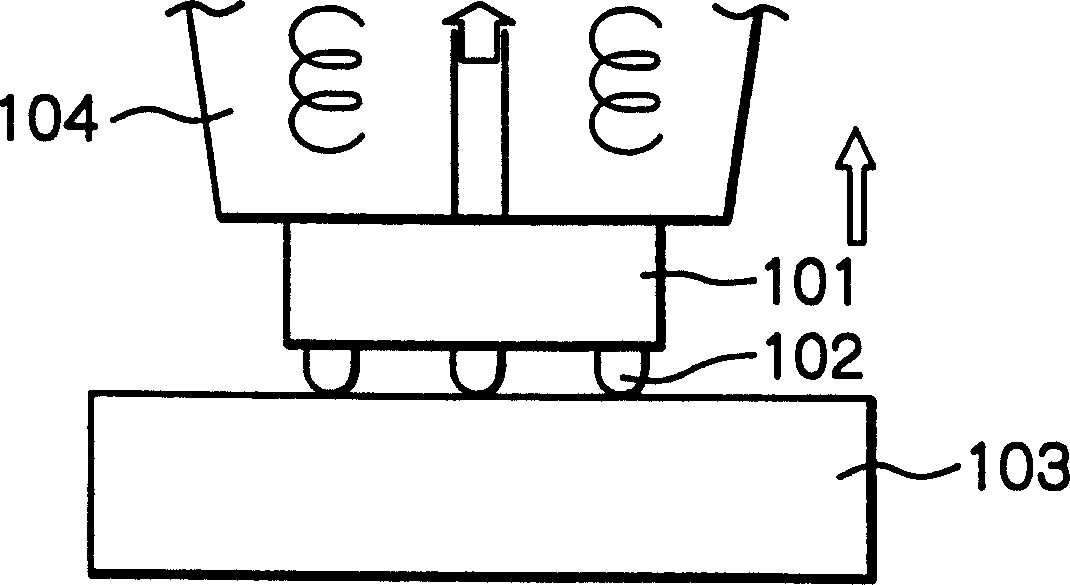

The invention provides a microwave multi-chip packaging structure using a silicon through hole and a manufacture method thereof. The method uses a temperature safety valve (TSV) to achieve two-sided integrated system-stage packaging structure, when a monolithic microwave integrated circuit (MMIC) chip needs integrating, a user does not need embed a substrate before wiring, and performance, reliability and rate of finished products of the packaging structure are improved. Simultaneously, processes such as injection, corrosion, release and high temperature annealing in a manufacture process can be used before integration of the MMIC, and components needing special processes can be assembled and integrated in advance on the other side of the substrate. Therefore, the substrate comprising active and passive devices, micro-electromechanical systems (MEMS), photoelectric devices and the like can be conveniently manufactured in a large scale before integration of the MMIC, and the manufacture method is simple in process, reduces cost, and is advanced and reliable at present.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

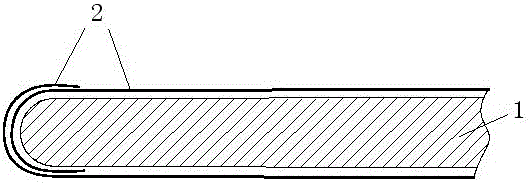

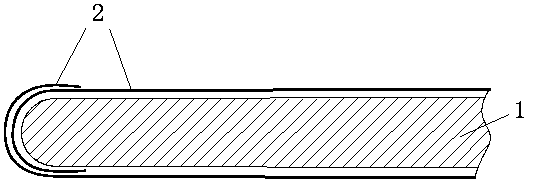

High strength ultrafine fiber simulation composite lether and its manufacturing method

The present ivnention relates to a high-strength ultrafine fibre imitation leather. It is made up by using sea-island ultrafine fibre base cloth through processes of impregnating with polyurethane, extracting treatment and after-finishing. The described base cloth is a double-layer or more than double-layer composite base cloth formed from sea-island composite fibre woven fabric and non-woven fabric which are combined together by means of needling process or cohesive process, then said invention makes the composite base cloth undergo the processes of impregnating with polyurethane, hardening, extracting 'sea' component in the solvent capable of removing 'sea' component from sea-island fibre to obtain semifinished product, widening forming, mellowing, dyeing, grinding or sticking film so as to obtain the invented product.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Bulked ammonium nitrate explosive with low explosion speed and its prepaing process

InactiveCN1386727ANo pollution in the processLow costNon-explosive/non-thermic compositionsDiluentAmmonium nitrate

A puffed ammonium nitrate explosive with low exploding speed is prepared from ammonium nitrate, surfactant, composite oil, wood powder, and diluent through dissolving ammonium nitrate and surfactant in water, vacuum drying at 110-140 deg.C and -0.085--0.098 MPa vacuity for 5-20 min, mixing with others and cooling. Its advantages are high safety and performance, uniform explosion transmission and low cost.

Owner:NANJING UNIV OF SCI & TECH

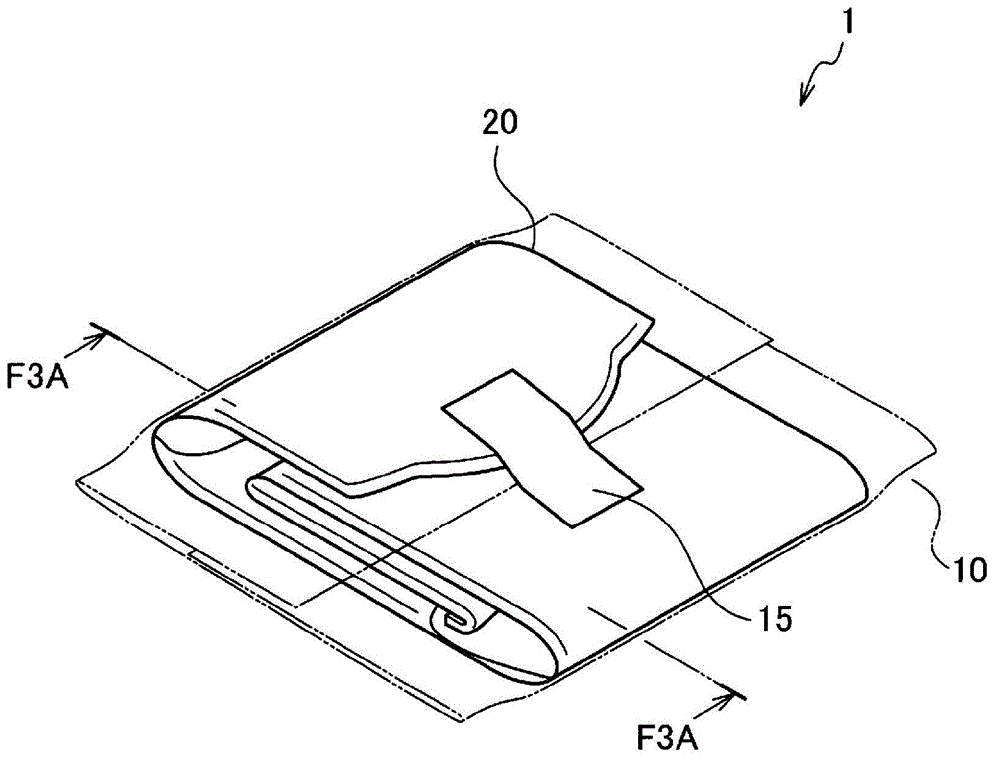

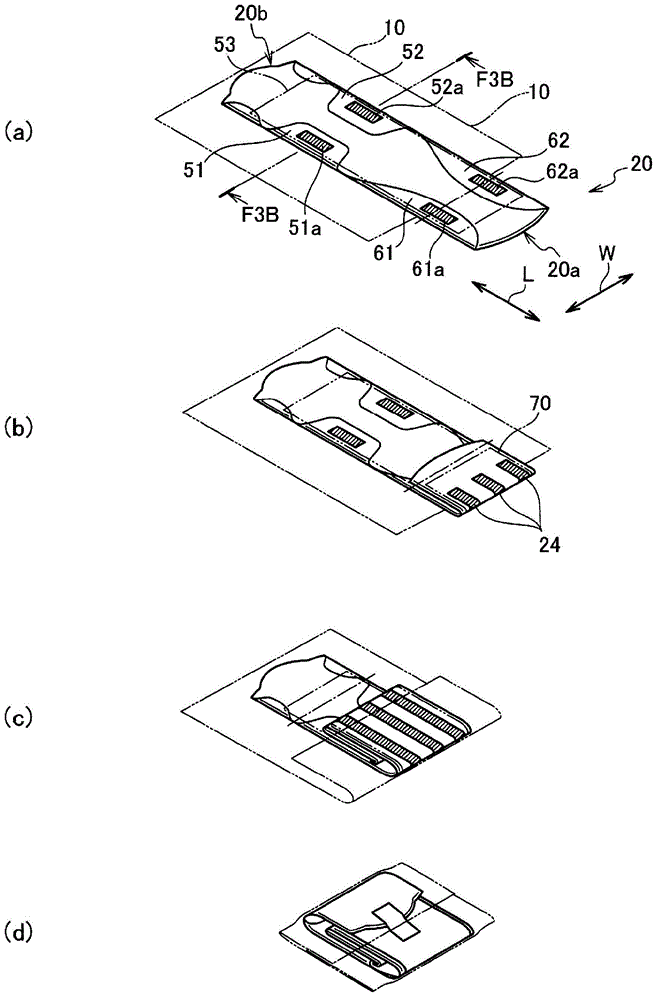

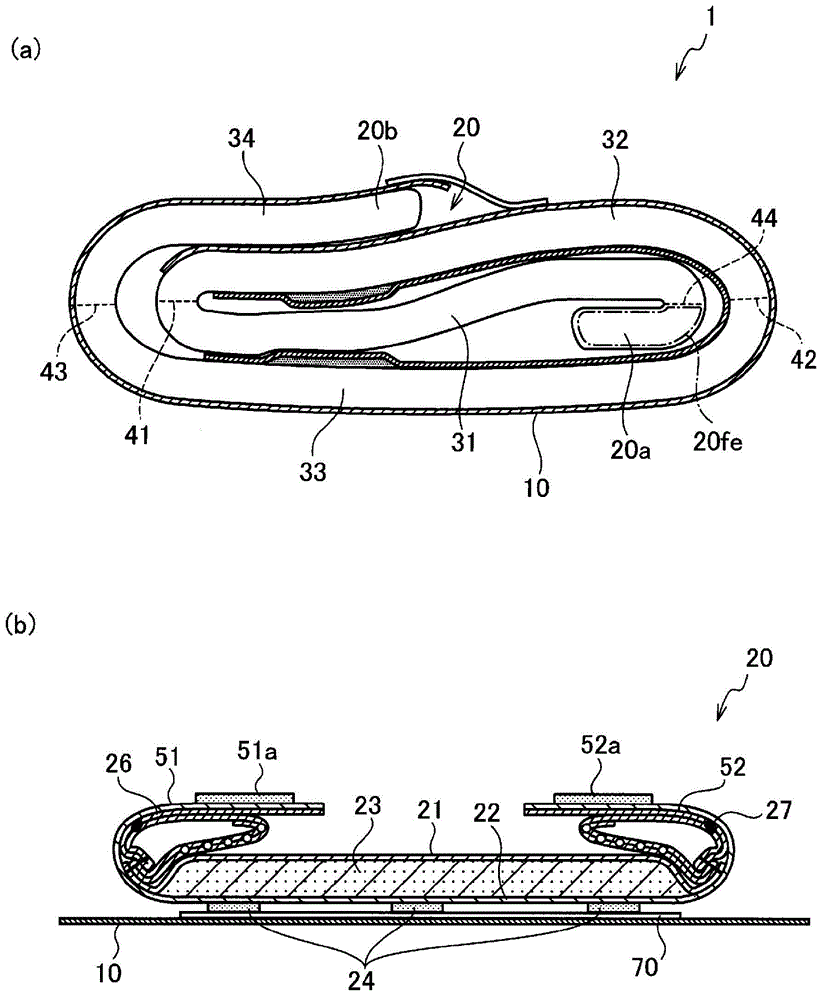

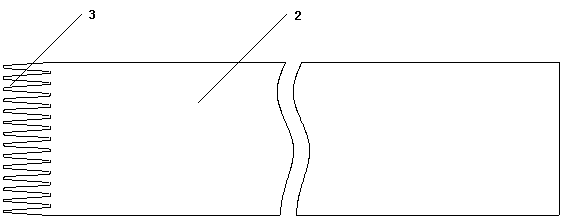

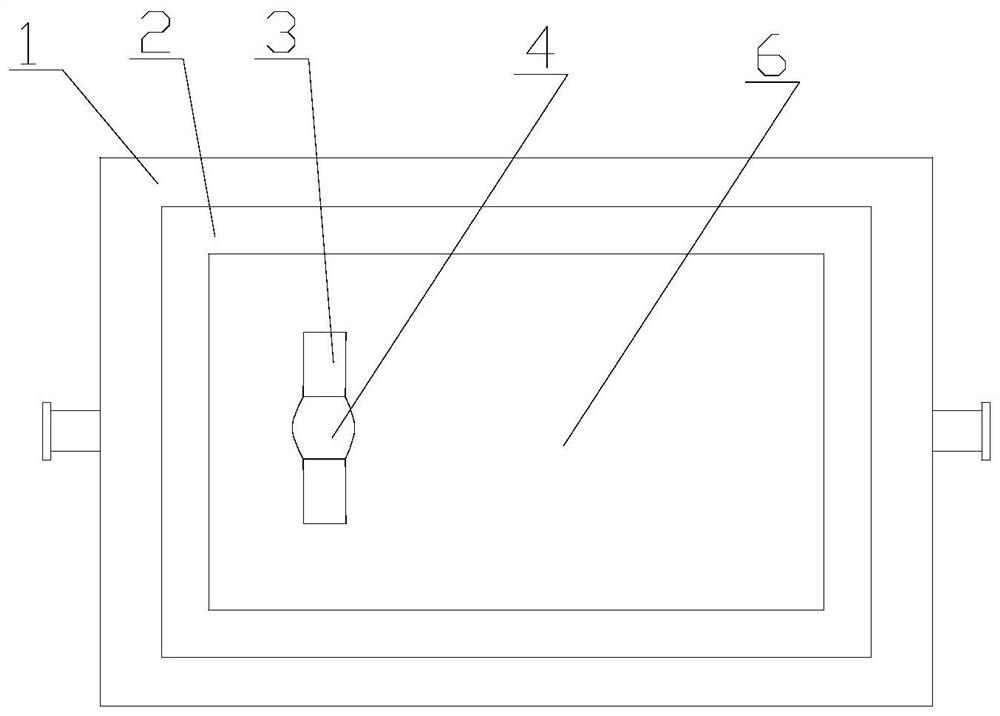

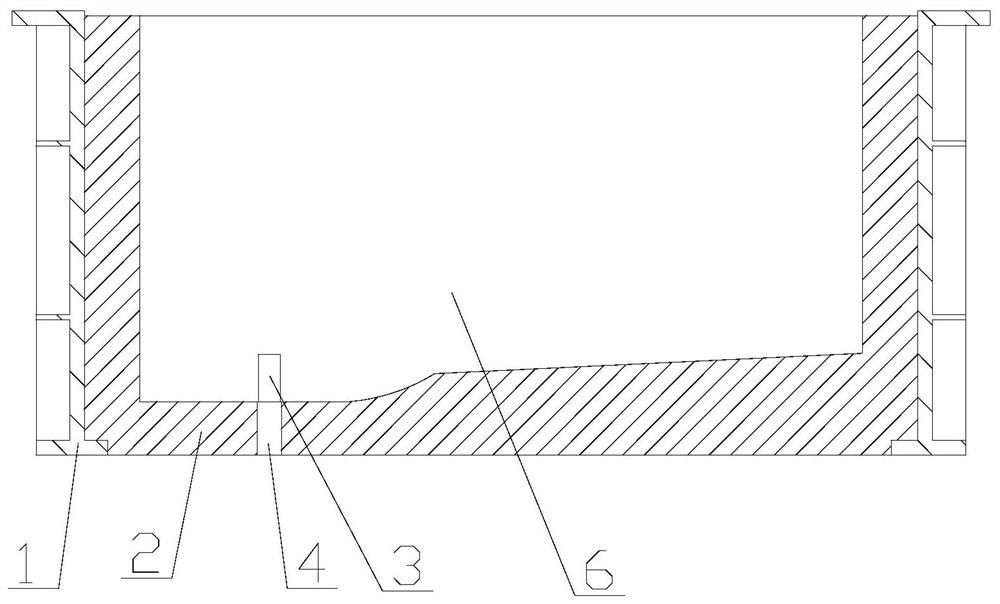

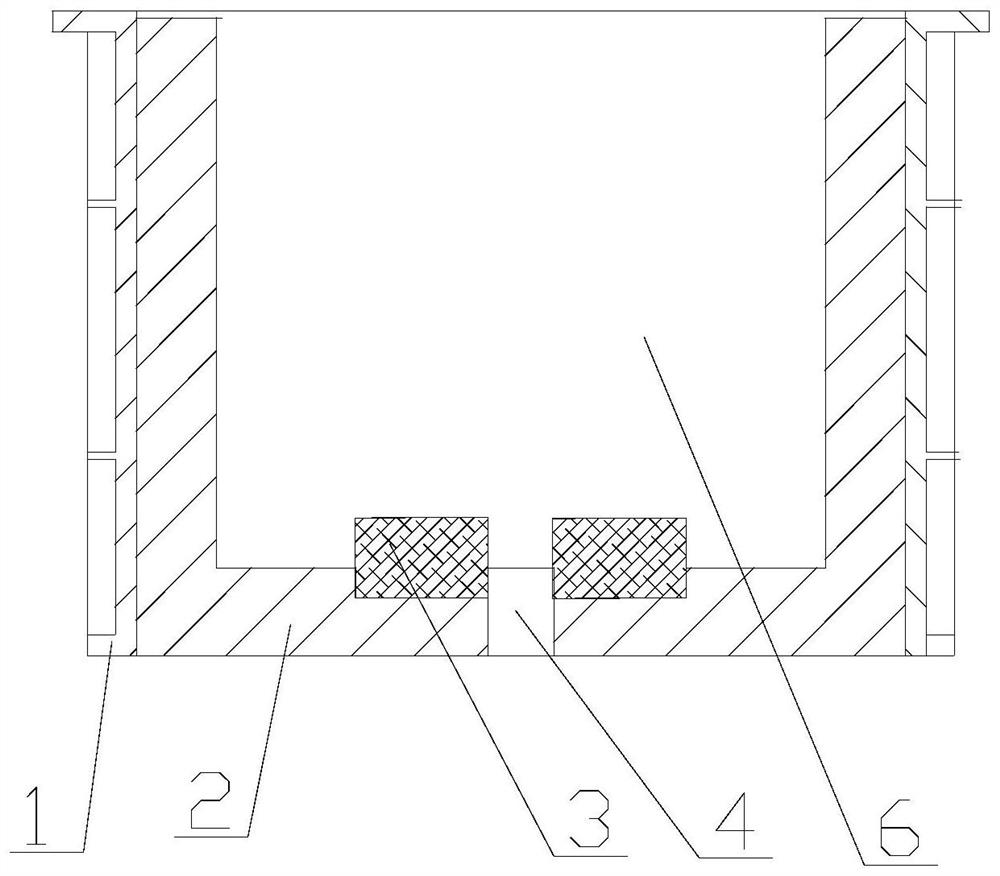

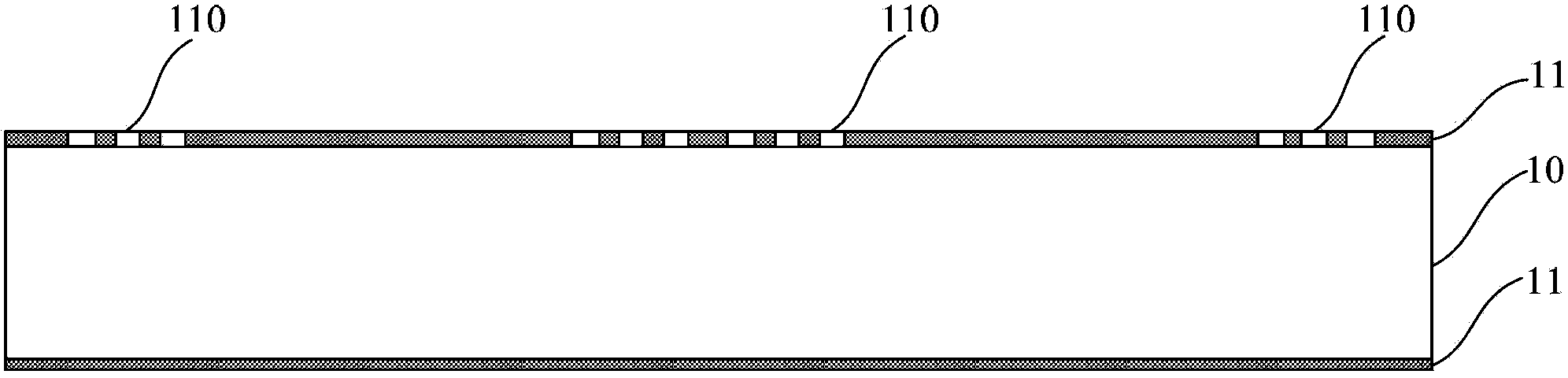

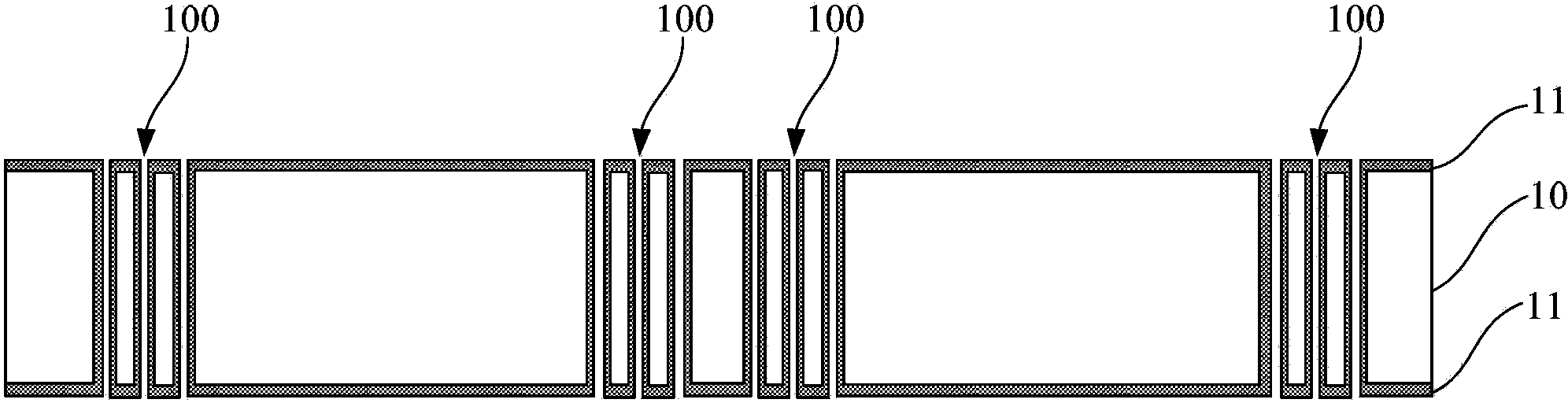

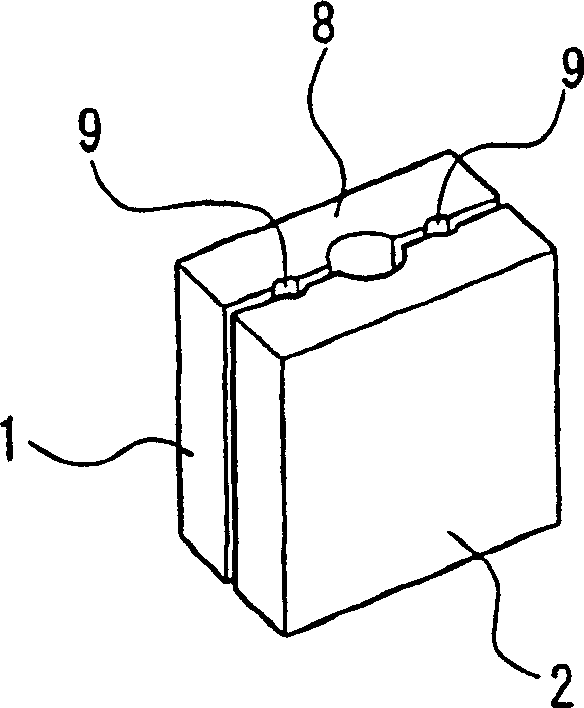

Packaging structure of absorbent article, and method for manufacturing the same

InactiveCN102753126AReliable Packaging ConstructionReliable manufacturing methodSanitary towelsBaby linensMechanical engineeringSanitary napkin

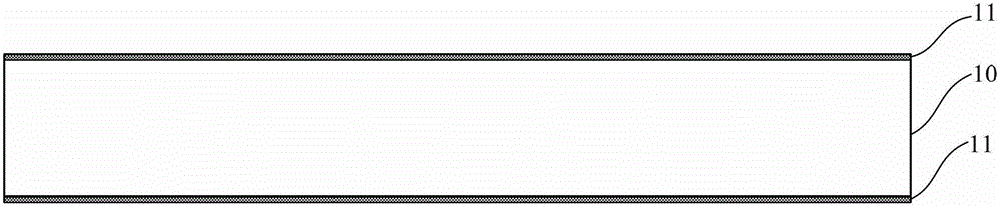

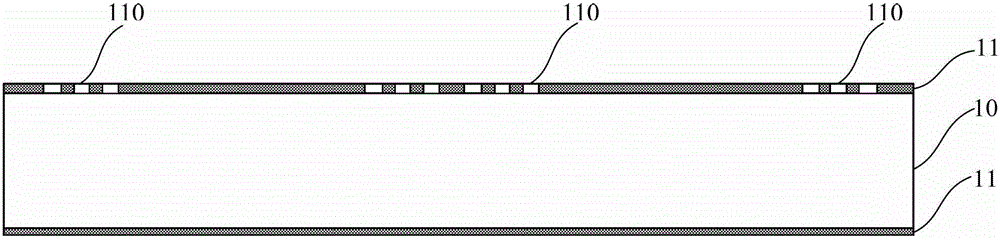

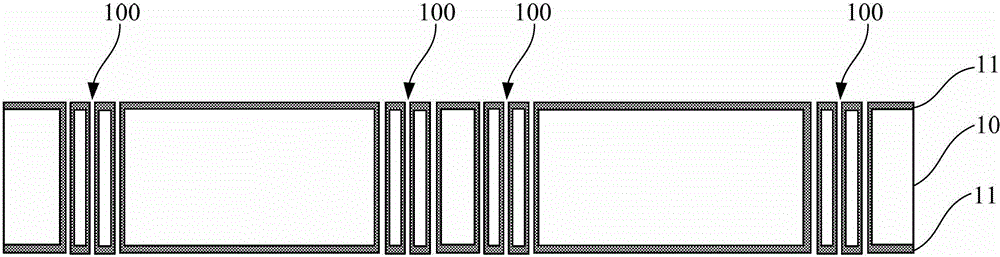

A packaging material (10) is provided only on the non-skin side surface of a third portion (32) and a fourth portion (33), and the length of the packaging material (10) in the longitudinal direction of a sanitary napkin (20) is less than the length of the sanitary napkin (20). A second portion (31) has a folding end section (20fe) which appears when a first folding section (44) is folded. The first folding section (44) is provided at a first portion (20a) side, opposes a first folding bent portion (41), of the sanitary napkin (20). The folding end section (20fe) is folded and bent onto the non-skin side surface of the second portion (31).

Owner:UNI CHARM CORP

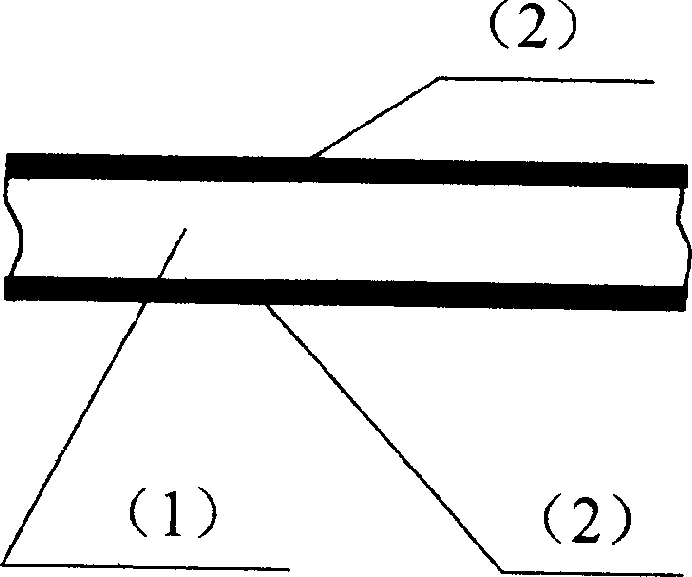

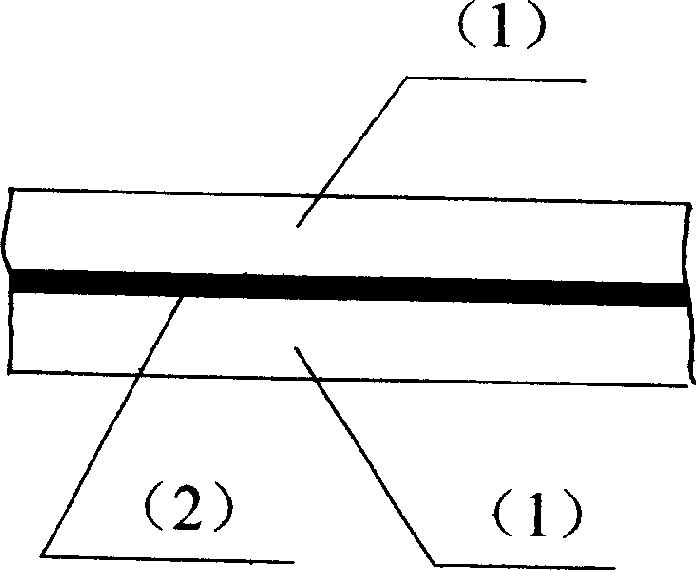

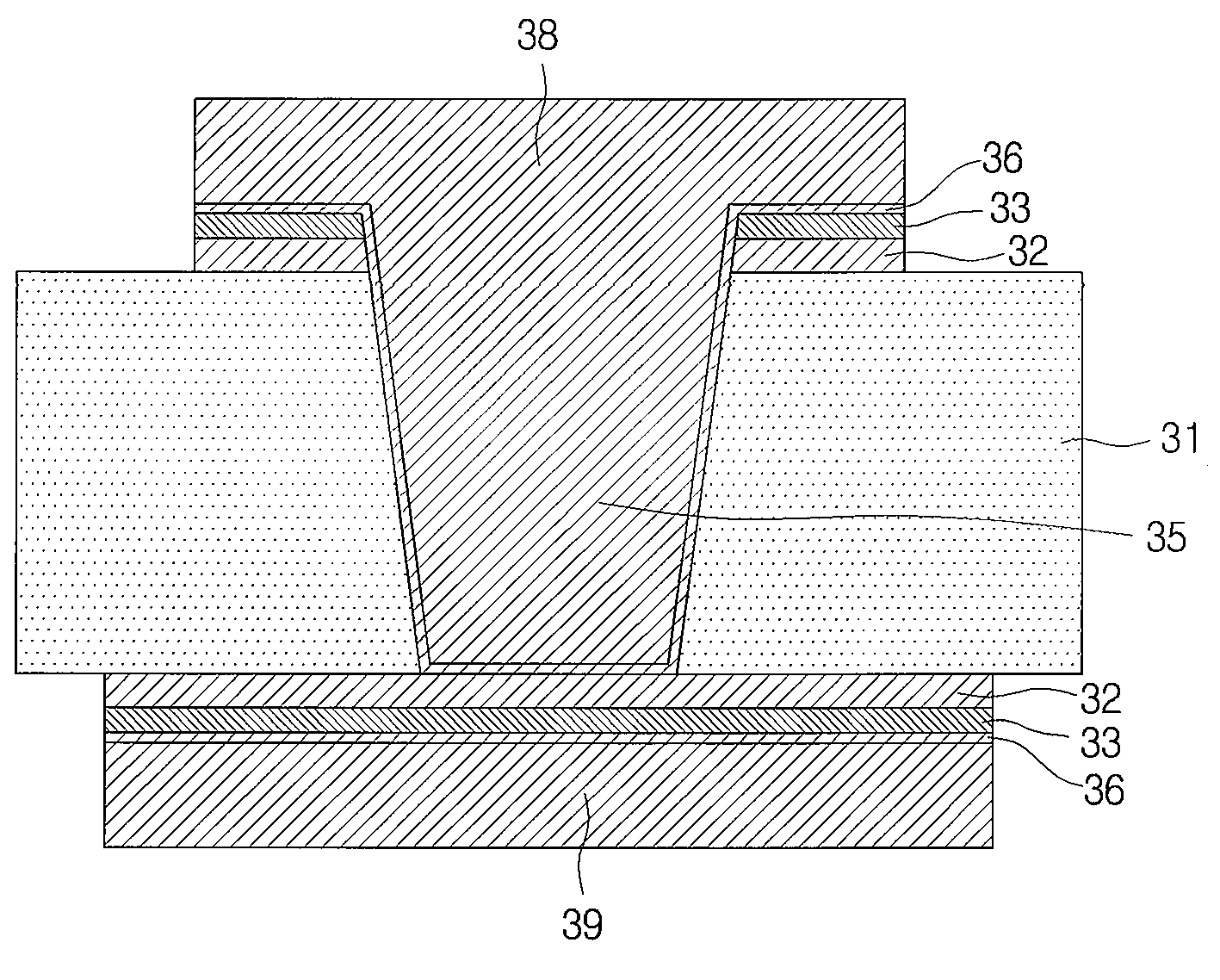

Manufacturing method of printed circuit board

InactiveUS20090321387A1High densityReliable manufacturing methodDecorative surface effectsPrinted circuit aspectsEngineeringConductive materials

Disclosed is a manufacturing method of a printed circuit board. The method in accordance with an embodiment of the present invention includes: providing a laminated substrate having an insulator as well as a first metal layer and a second metal layer, which are sequentially laminated on one side of the insulator; processing a via hole in the laminated substrate; forming a seed layer on an inner wall of the via hole and on a surface of the second metal layer; plating an inside of the via hole and the surface of the second metal layer with a conductive material that is different from a material of the second metal layer; etching the seed layer and the conductive material, formed on the second metal layer; etching the second metal layer; and forming a first circuit pattern by selectively etching the first metal layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

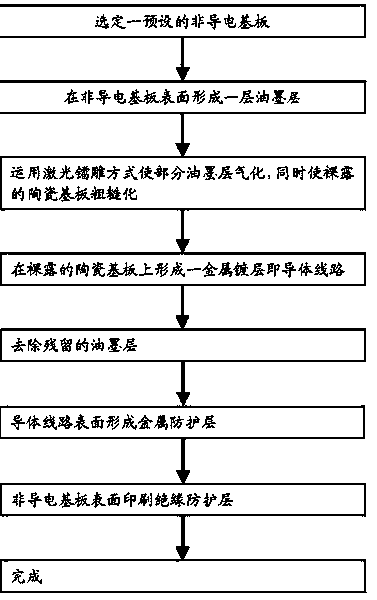

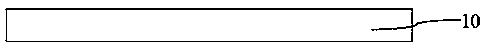

Manufacturing method for forming conductor line on non-conductive substrate

InactiveCN103533764AEasy to prepareReliable manufacturing methodConductive pattern formationMetal coatingElectrical conductor

The invention provides a manufacturing method for forming a conductor line on a non-conductive substrate. The manufacturing method comprises the following steps that: A, a non-conductive substrate is selected; B, a printing ink layer is formed on the surface of the non-conductive substrate; C, laser engraving is performed on the printing ink layer and the surface of the non-conductive substrate through laser, and the laser is utilized to divide the printing ink layer into a plurality of continuous or non-continuous different regional blocks, and then, printing ink layer segments of the non-continuous regional blocks are removed through gasification such that portions of the non-conductive substrate where the non-continuous regional blocks are located are revealed; D, metallization processing is performed on the surfaces of the revealed portions of the non-conductive substrate such that the conductor line which is composed of a metal coating can be formed: D, remaining printing ink layer segments are removed, and the conductor line is formed on the non-conductive substrate.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

Explosion welding explosive with low explosion velocity

InactiveCN101602636AImprove mixing uniformitySimple production processExplosivesNon-electric welding apparatusWaxLow speed

The invention discloses an explosion welding explosive with a low explosion velocity for explosion welding between metal sheet materials and preparation method thereof. The explosion welding explosive consists of 66 to 76 portions of ammonium nitrate, 3 to 5 portions of composite oil phase and 21 to 29 portions of doped powder, wherein the composite oil phase consists of 2.6 to 4.8 portions of solid wax and 0.2 to 0.4 portion of stearic amine salt; and the doped powder consists of 15.95 to 23.2 portions of ferric oxide powder and 5.04 to 8.9 portions of diatomite powder. The preparation method comprises the following steps: adding water with 8 to 12 mass percent of the ammonium nitrate into the ammonium nitrate; heating and dissolving the mixture to obtain aqueous solution of ammonium nitrate; under low-speed stirring, dispersing the composite oil phase and the doped powder respectively into the aqueous solution of the ammonium nitrate; mixing and heating the mixed solution till a temperature of between 105 and 125 DEG C to obtain suspended mixed solution; removing moisture in a vacuum tank with vacuum degree of between 0.07 below zero and 0.09 MPa below zero; and cooling, sieving and filling the explosive to obtain the explosion welding explosive with the low explosion velocity of less than 2,400 m / s. Explosive particles have good dispersion and are convenient to distribute; and the explosive has low explosion velocity and stable explosion performance and can meet the requirement of the explosive for the explosion welding of different metal materials.

Owner:黄文尧

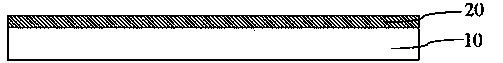

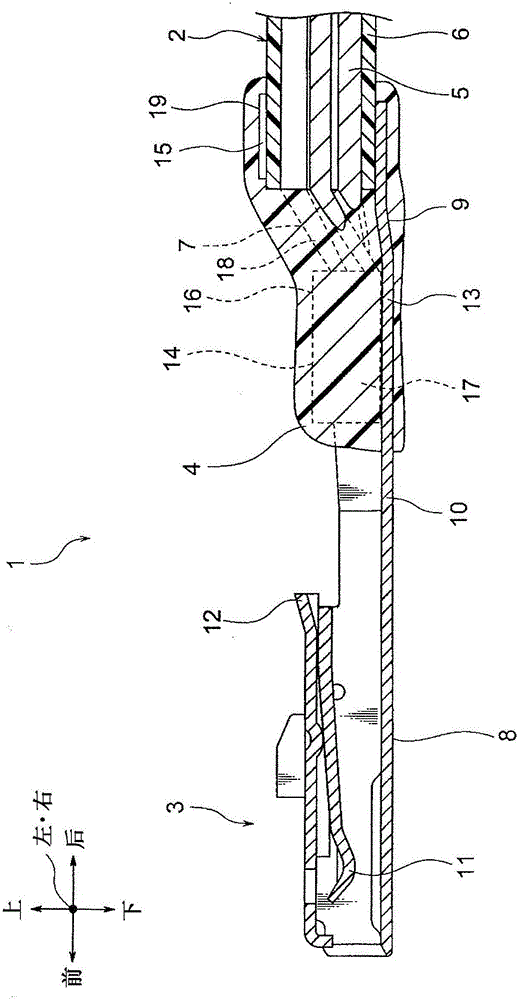

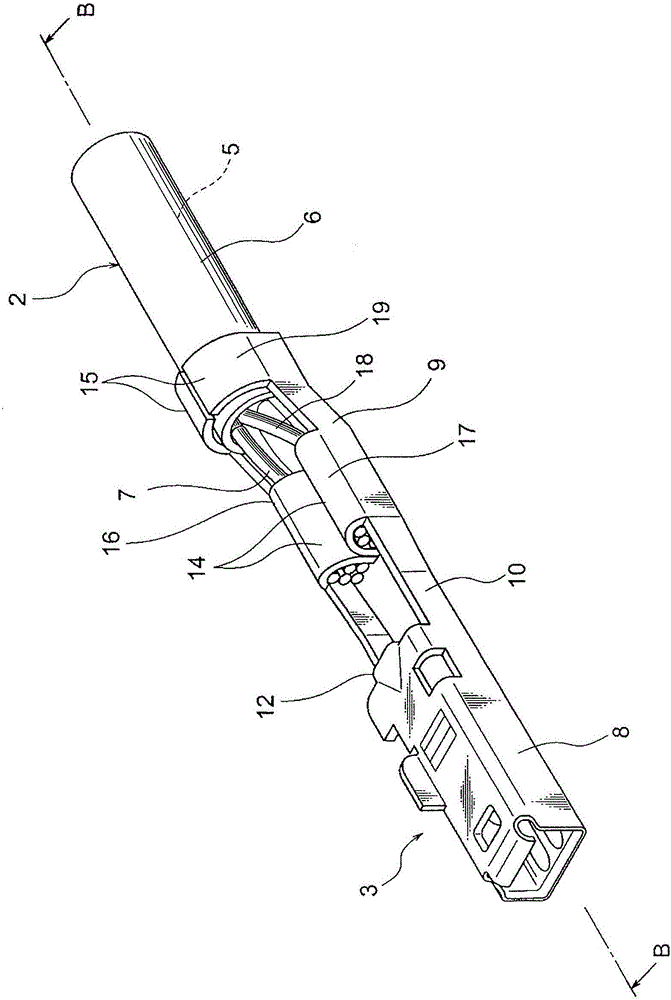

Terminal with wire, manufacturing method of terminal with wire, and wire harness

InactiveCN106169661AEfficiently provideImprove sealingContact member assembly/disassemblyCoupling contact membersElectrical conductorElectric wire

A terminal with a wire having a high sealing property, a manufacturing method thereof, and a wire harness are provided. The terminal with the wire includes an aluminum wire and a crimp terminal. A resin covering member is removed from the aluminum wire to form a conductor exposed portion (a wire forming process). The crimp terminal is connected to the conductor exposed portion to form a wire-terminal connection portion (a wire-terminal connection process). Then, an anticorrosion portion is formed such that a voltage is applied between the crimp terminal and a metal nozzle and an electrified anticorrosion material is supplied from the metal nozzle to the wire-terminal connection portion in a state of being attracted (an anticorrosion material supply process). Further, the anticorrosion portion is formed by irradiating the anticorrosion material with an ultraviolet ray to be UV-cured (an anticorrosion material curing process).

Owner:YAZAKI CORP

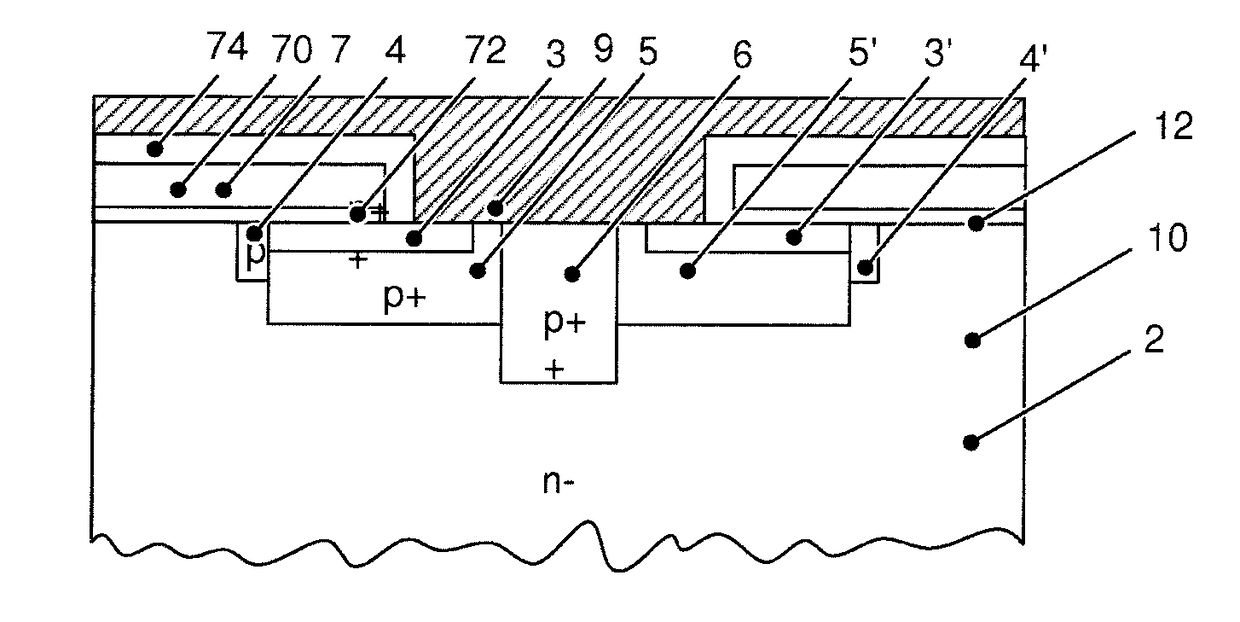

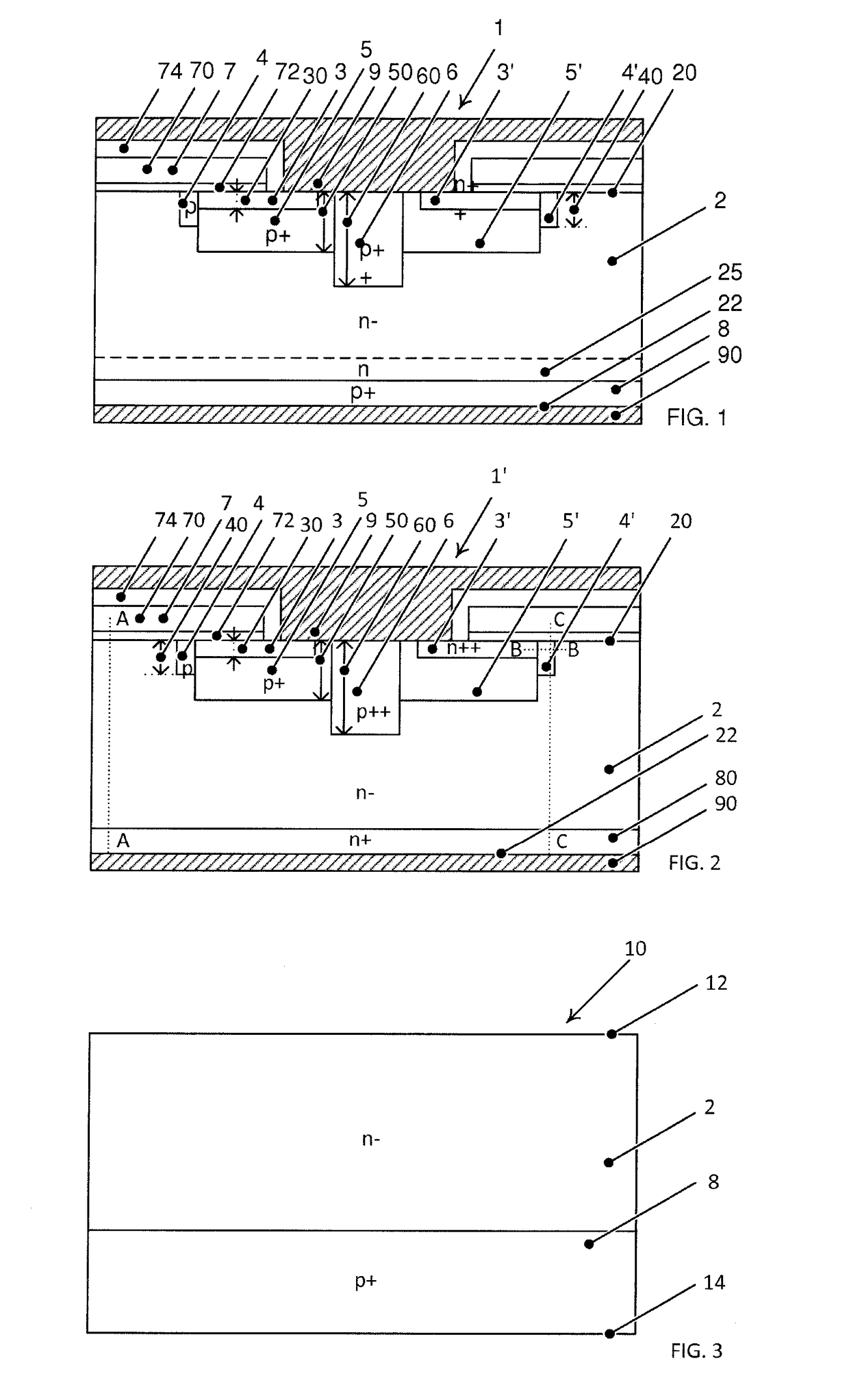

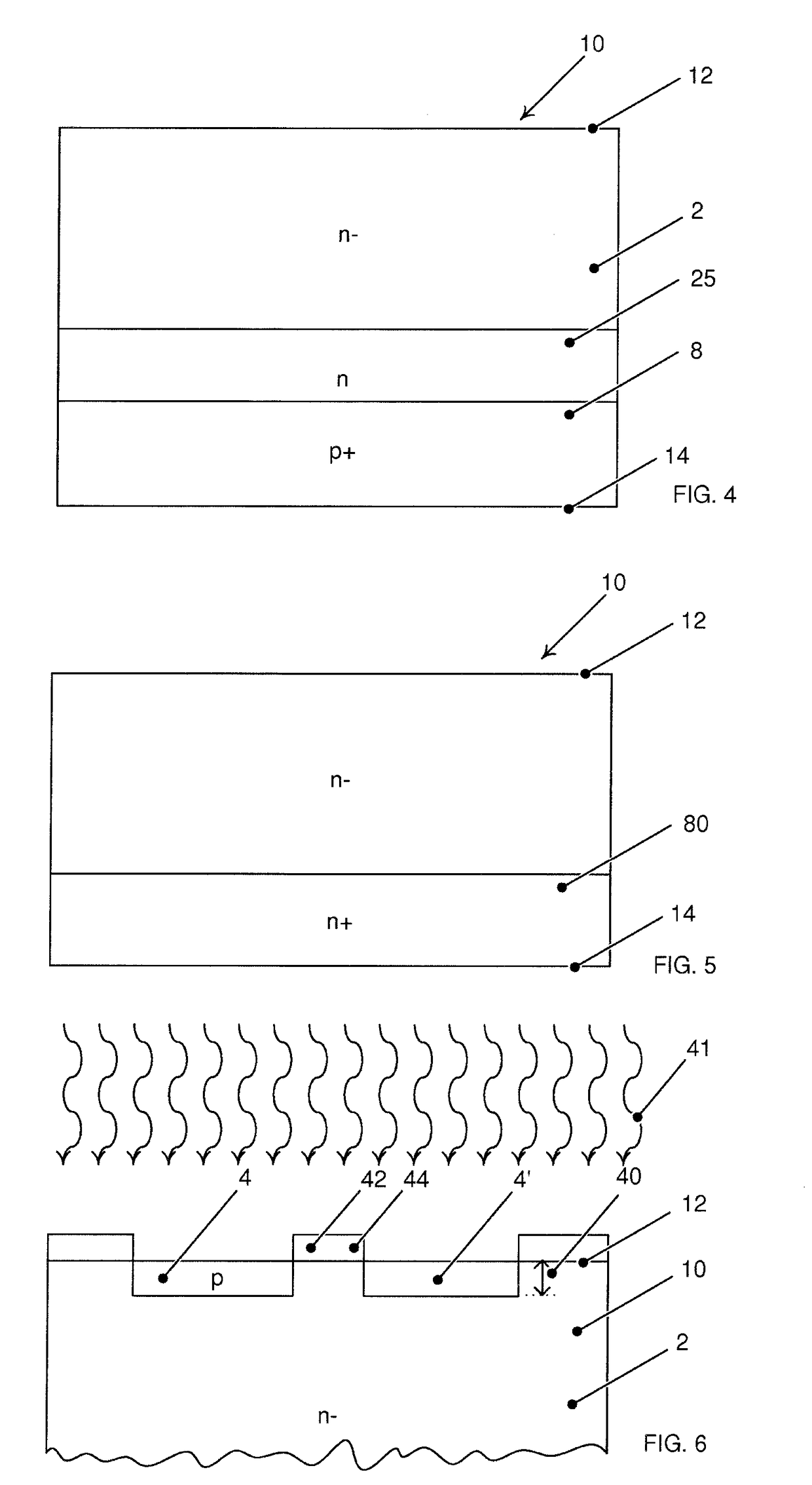

Semiconductor device and method for manufacturing such a semiconductor device

ActiveUS20180286963A1The device operates reliablyReduce doping concentrationTransistorSemiconductor/solid-state device manufacturingDopantPower semiconductor device

A method of manufacturing a semiconductor device is provided with: (a) providing a wide bandgap substrate product, (b) for forming two channel layers applying a first mask and applying a p first dopant, for forming two source regions forming a second mask by applying a further layer on the lateral sides of the first mask and applying an n second dopant, for forming two well layers forming a third mask by removing such part of the second mask between the source regions and applying a p third dopant, wherein a well layer depth is at least as large as a channel layer depth, (c) after step (b) for forming a plug applying a fourth mask, which covers the source regions and the channel layers and applying a p fourth dopant to a greater depth than the well layer depth and with a higher doping concentration than the well layers; wherein the well layers surround the plug in the lateral direction and separate it from the two source regions.

Owner:HITACHI ENERGY SWITZERLAND AG

Dust settling water bag for blasting demolition of buildings

InactiveCN102527689AWith sticky dust covering effectIncrease in sizeFouling preventionDetonatorAlcohol

The invention discloses a dust settling water bag for blasting demolition of buildings, which consists of slurry, a blasting device and a blasting-proof water bag. Raw materials of the slurry include, by weight, 96-98kg of water and 2-4kg of dust adhesive. Raw materials of the dust adhesive include, by weight, 1.0-2.2 kg of cohesive soil, 0.3-0.5kg of binder, 0.3-0.5kg of sodium alcohol ether sulphate and 0.4-0.8 kg of table salt. The production steps of the dust settling water bag for blasting demolition of buildings include of preparing the dust adhesive by mixing the cohesive soil, the binder, the sodium alcohol ether sulphate and the table salt, preparing the slurry by adding water into the dust adhesive and uniformly stirring the same, producing the blasting device by inserting a detonator into 75-100g waterproof stick explosive, pouring 50-80kg of the slurry into the blasting-proof water bag, arranging the blasting device into the center of the blasting-proof water bag, thereby producing the dust settling water bag for blasting demolition of buildings. The dust settling water bag effectively solves the difficult problem that dust generated in blasting demolition of buildings flies anywhere in air, is low in cost and convenient in product and use and has the dust settling efficiency higher than 95%.

Owner:ANHUI UNIV OF SCI & TECH

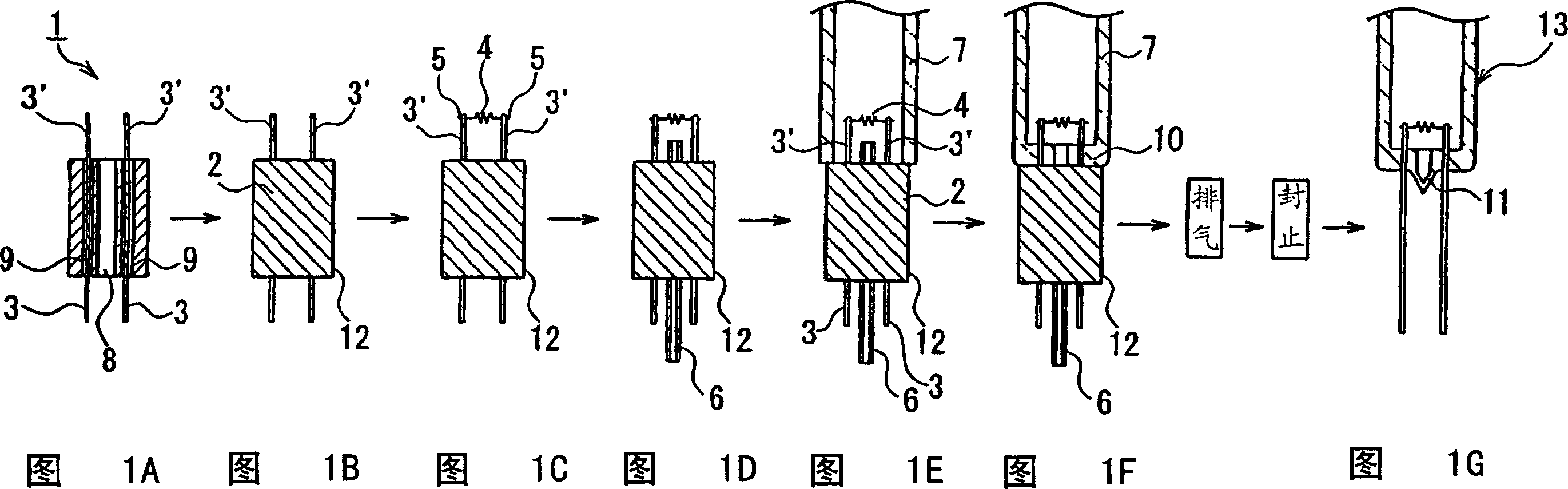

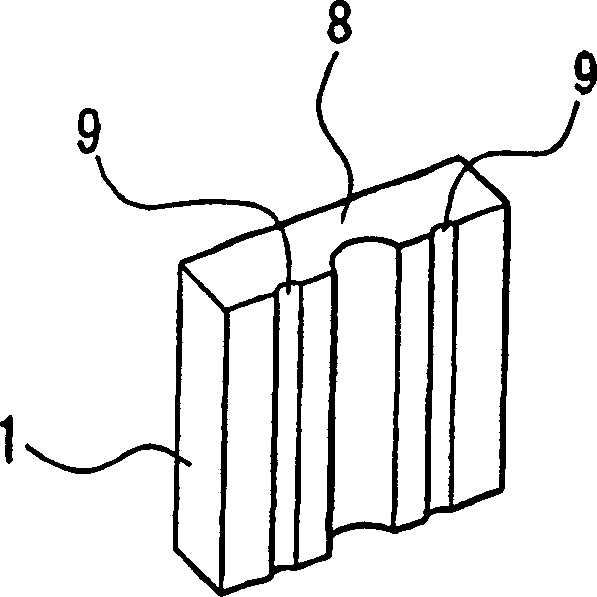

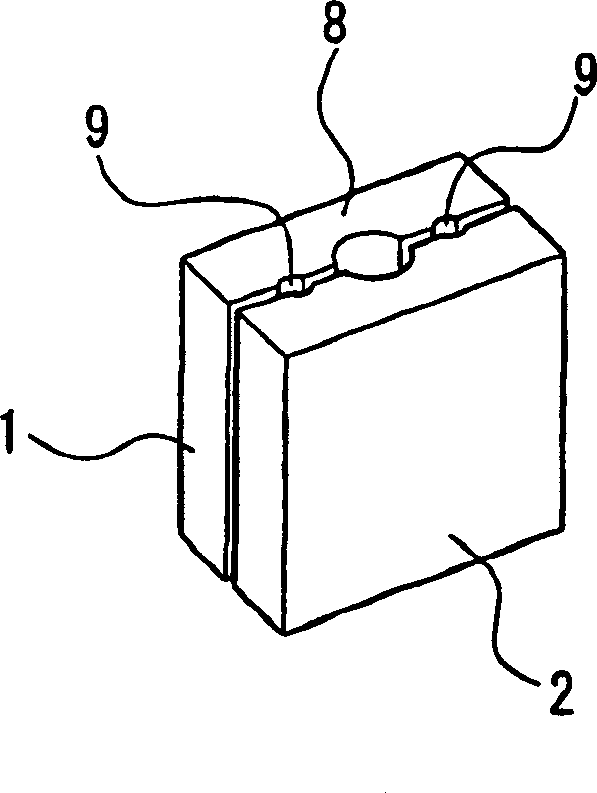

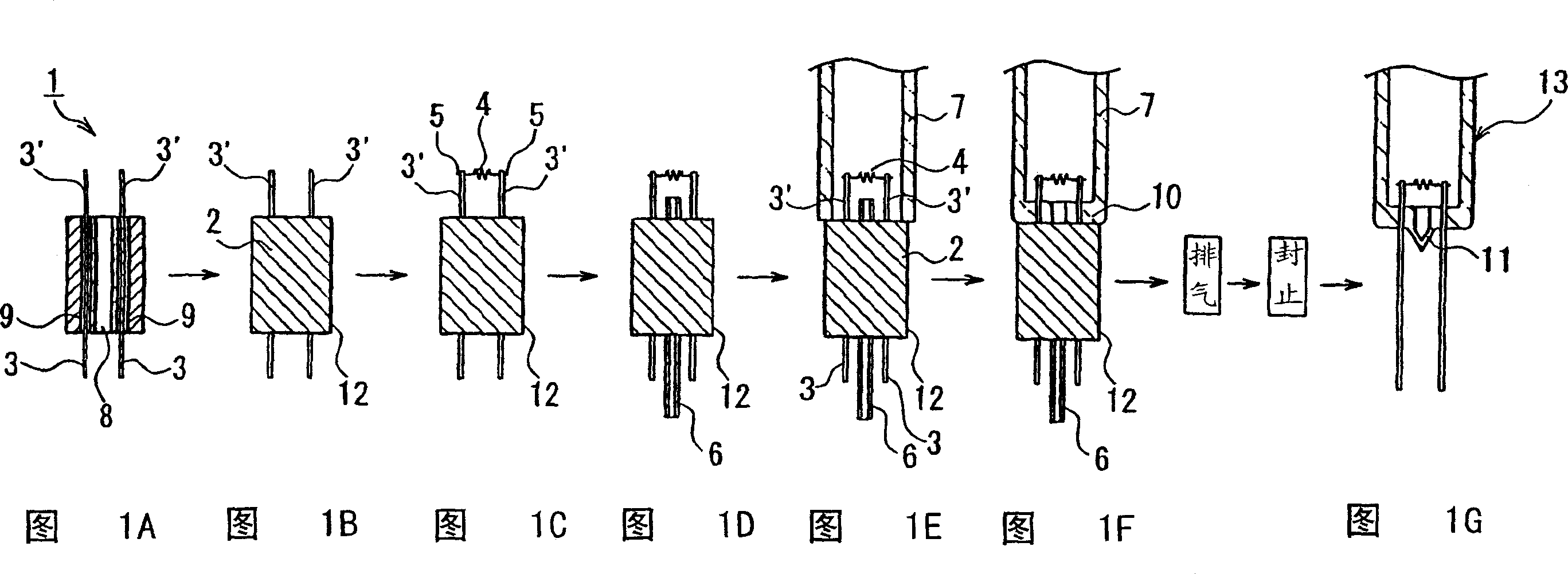

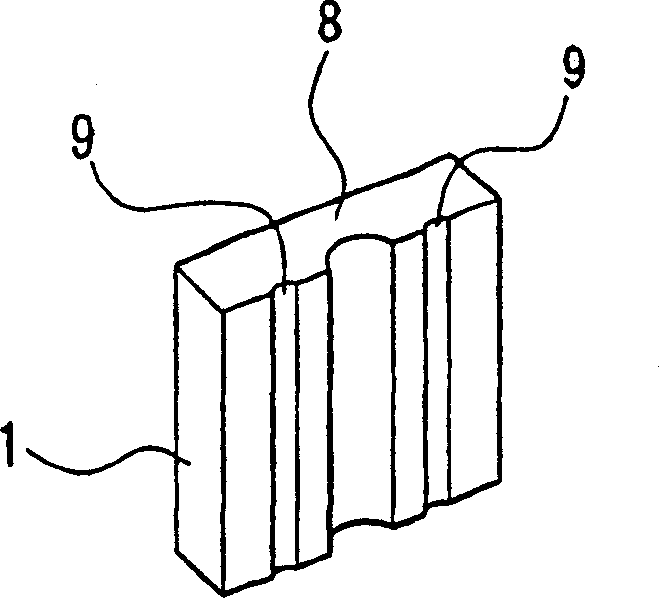

Fluorescent lamp producing method

InactiveCN1473343AEasy to prepareReliable manufacturing methodTube/lamp screens manufactureTube/lamp vessels closingFront end of lineEngineering

A fluorescent lamp is produced by substantially parallelly disposing, holding and fixing a pair of lead wires (3, 3) between a block-like holder and a block-like auxiliary holder (2), attaching an electrode (4) to the tips (3', 3') of the projecting lead wires (3, 3), disposing an exhaust pipe (6) with its opposite ends positioned outside an exhaust pipe receiving groove, inserting the electrode (4) and exhaust pipe (6) into the end of a glass tube (7), heating the glass tube adjacent its end to effect the heat pinch seal of the lead wires, thus integrating the glass tube and exhaust pipe, evacuating the glass tube through the exhaust pipe, removing the block-like holder and block-like auxiliary holder, heat-sealing the tip of the glass tube , and cutting away the exhaust pipe. It is possible to provide a fluorescent lamp producing method that is simple, reliable and stable, with nothing but the electrode existing between the lead wires.

Owner:PANASONIC CORP

Flip-chip semiconductor device with stress absorption layer made of resin and its manufacture method

InactiveCN1221026CReliable manufacturing methodSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

In a flip-chip type semiconductor device, a plurality of pad electrodes are formed on a semiconductor substrate. An insulating stress-absorbing resin layer made of thermosetting resin is adhered to the substrate as a composite layer in conjunction with a first conductive layer and has openings corresponding to the pad electrodes. A plurality of metal bumps are formed on the conductive layer.

Owner:RENESAS ELECTRONICS CORP

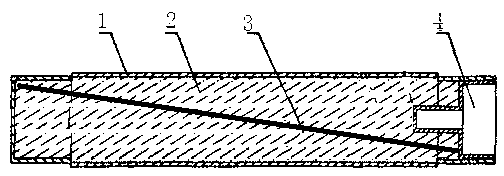

Method for manufacturing composite pipe with solid end sealed

The invention relates to a method for manufacturing a composite pipe with a solid end sealed and belongs to the field of fiber reinforced composite pipe fitting manufacturing. The method comprises the steps that a columnar male mould with the front end machined to be round or oval or in other similar round shapes is prepared, and in addition, the surface of the columnar male mould is coated with a demoulding material; composite prepreg is prepared, and a punching opening is formed in the front end of the prepreg through machining; the composite prepreg is laid on the surface of the columnar male mould in a covering manner, a punching opening part extends out of the front end of the mould in the twisting process, and a prepreg part extending out of the front end of the mould is bent for sealing; a BOPP band is tightly wound to the surface of the composite prepreg part obtained after laying and covering are completed; the composite prepreg obtained after the BOPP band is completely wound, together with the columnar male mould, is placed on a curing device, and a sealed solid end part is cured preliminarily; the pipe obtained after preliminary curing of the sealed solid end part is completed, together with the columnar male mould, is taken out of the curing device and placed in a curing oven for overall curing; and after the temperature is lowered, the columnar male mould is released in a physical-pulling manner, and the BOPP band is removed, so that the composite pipe with the solid end sealed is obtained.

Owner:WEIHAI GUANGWEI COMPOSITES +1

High-density high-explosion-speed water gel explosive seismic charge and preparation method thereof

The invention discloses a high-density high-explosion-speed water gel explosive seismic charge and a preparation method thereof. The high-density water gel explosive in the seismic charge comprises a high energy additive which comprises, by weight, 46-60 parts of paint grade aluminum powder, 31-40 parts of ferrosilicon powder, 4-6 parts of liquid paraffin and 5-8 parts of turpentine. The paint grade aluminum powder and the ferrosilicon powder are added to a mixed solution of the liquid paraffin and turpentine to prepare the high energy additive. The preparation method comprises the following steps: sequentially adding a monomethylamine nitrate solution, ethylenediamine dinitrate, ammonium nitrate and an antifreeze agent under low speed stirring, controlling the temperature at 55-75DEG C, adding a mixture of sodium nitrate and Sesbania cannabina Pers powder, a crosslinking agent and the high energy additive, mixing to prepare the high-density water gel explosive, loading the high-density water gel explosive into a seismic charge housing inserted with a common detonating cord, and sealing to obtain the high-density water gel explosive seismic charge. The high-density water gel explosive seismic charge has the advantages of no containment of toxic substances of TNT and the like, high density, high explosion speed, large unit volume power, safety and environmental protection, certain pressure resistance and antifreeze performance, and simple preparation method.

Owner:淮北矿业控股股份有限公司 +1

Manufacturing method of composite material one-end-sealed solid-head pipe

Owner:WEIHAI GUANGWEI COMPOSITES +1

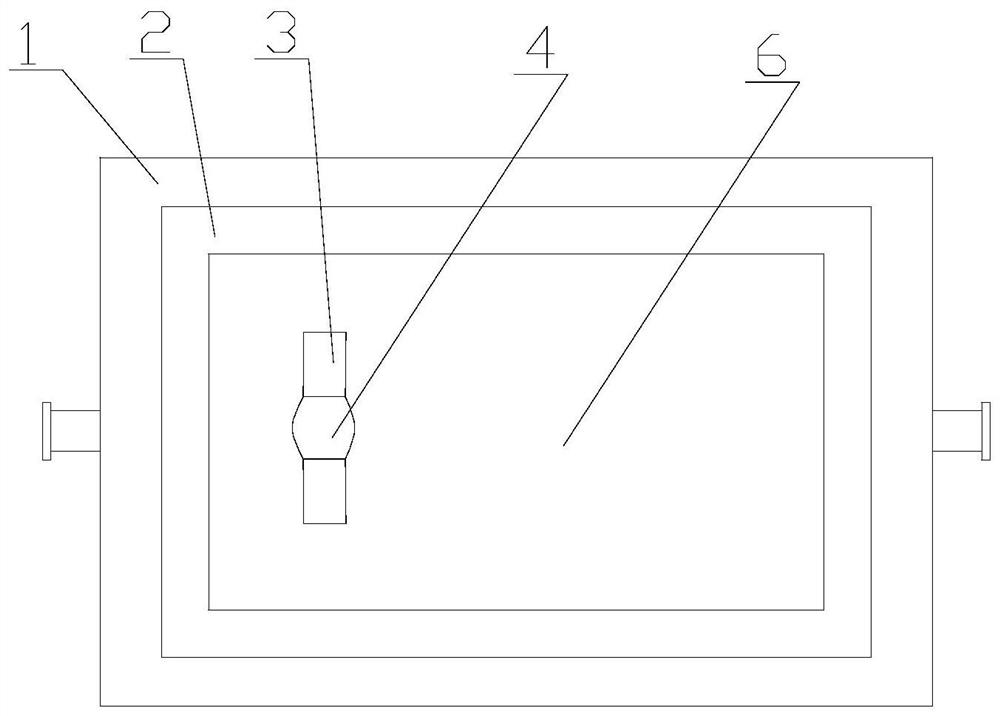

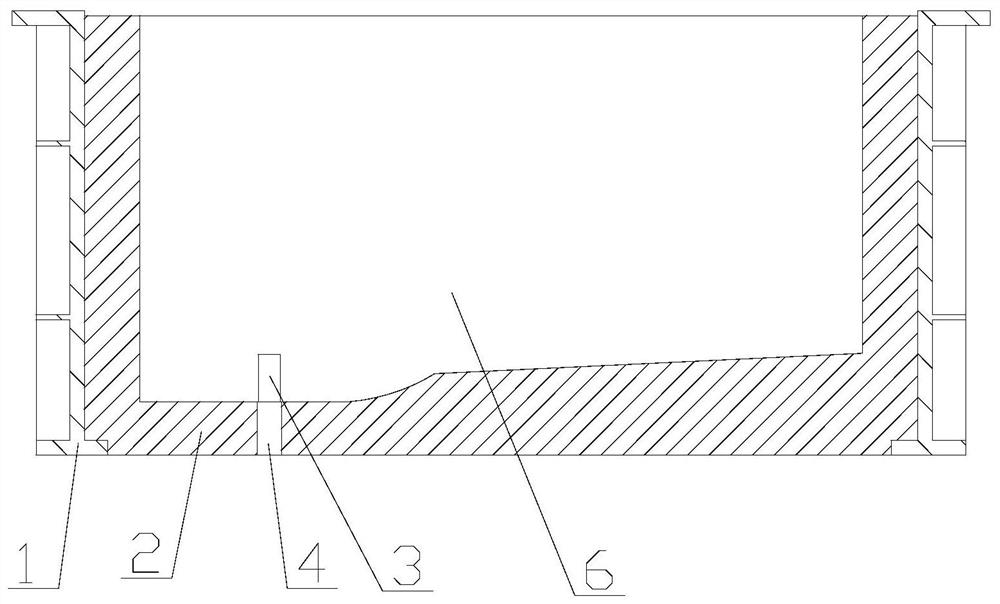

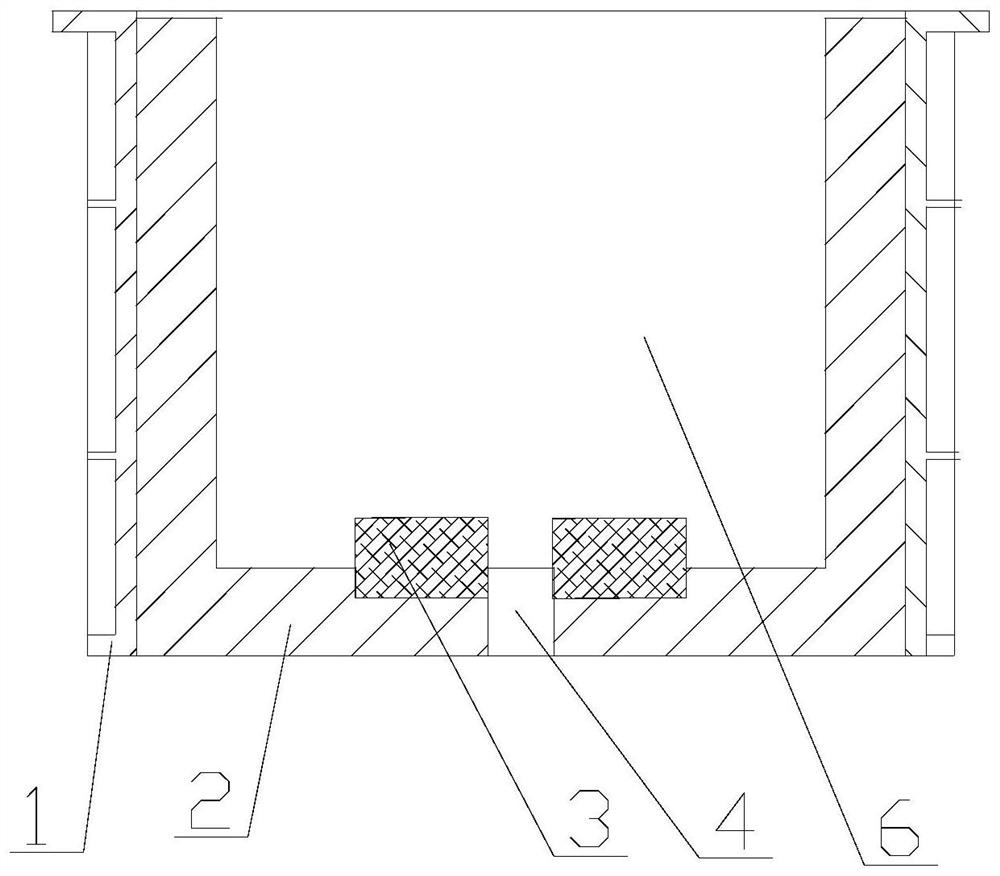

Anti-siphon pouring basin, and manufacturing method and using method thereof

ActiveCN112024826AAvoid quality defectsImprove product qualityFoundry mouldsProcess efficiency improvementSiphonEngineering

The invention relates to a pouring basin, and provides an anti-siphon pouring basin, and manufacturing and use thereof. The problems of slag inclusion, pores and other quality defects of castings dueto easy occurrence of siphon of the pouring basin are solved. The anti-siphon pouring basin comprises a pouring basin sand box, a pouring gate plug, a pouring basin molten metal containing chamber, asprue base and an anti-siphon dam; the pouring basin sand box is arranged on the outermost layer of the anti-siphon pouring basin, and the pouring basin molten metal containing chamber is arranged inthe anti-siphon pouring basin; the sprue base is arranged at the bottom of the pouring basin sand box, and the anti-siphon dam is connected to the sprue base. According to the anti-siphon pouring basin, no siphon phenomenon exists in the pouring process of the pouring basin, and vortexes are avoided; the conditions of slag inclusion and gas entrapment of products are reduced and the defects of slag inclusion and pores are reduced; gas entrapment, dross and molten slag entering a cavity are reduced, thereby benefiting guarantee of the quality of molten iron; and the product quality of the castings is improved. Meanwhile, the manufacturing method is simple, reliable and effective, and the manufacturing cost is low.

Owner:KOCEL EQUIP

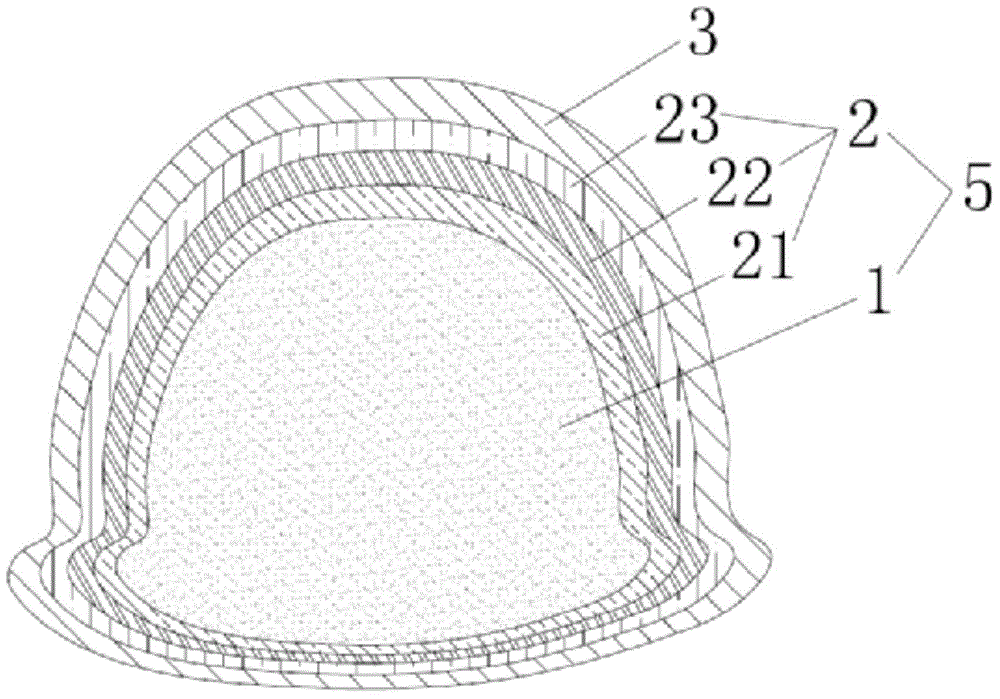

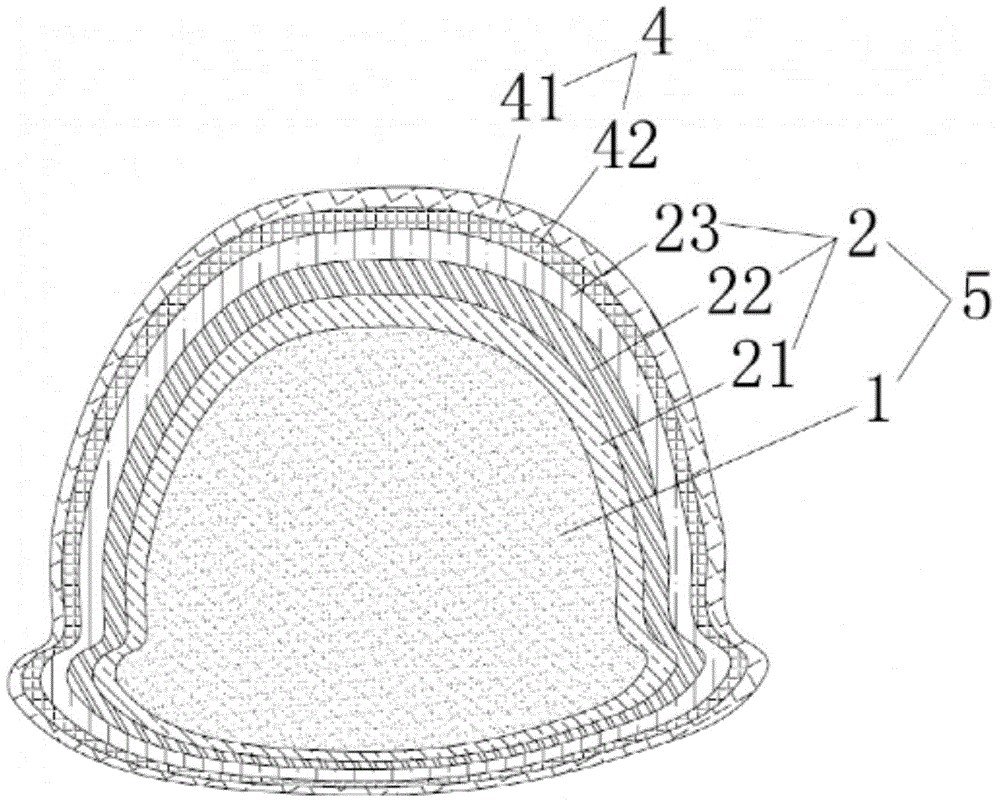

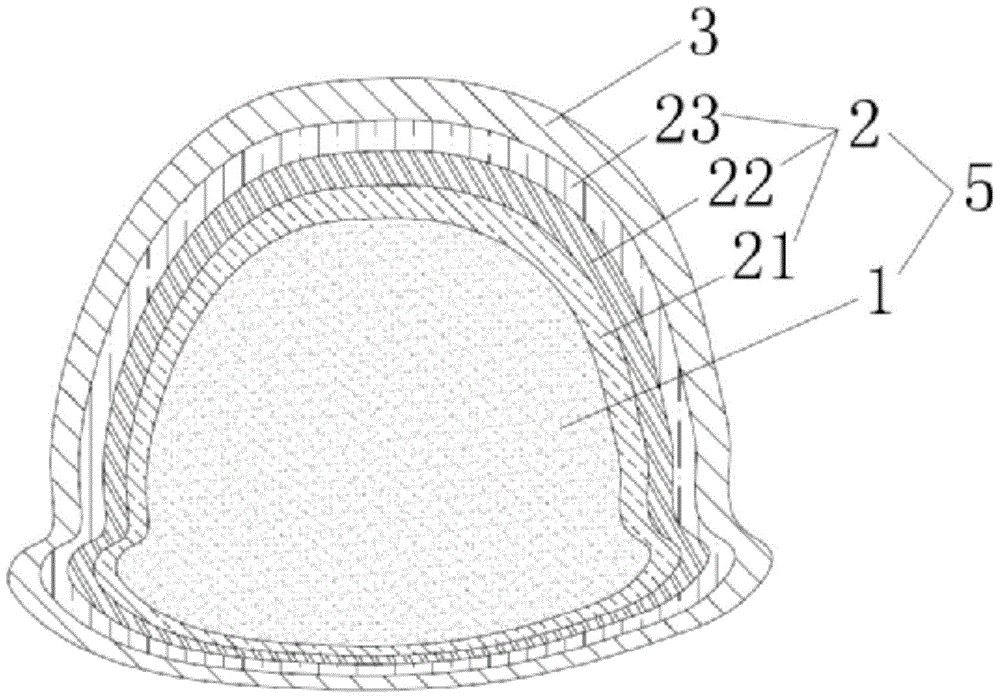

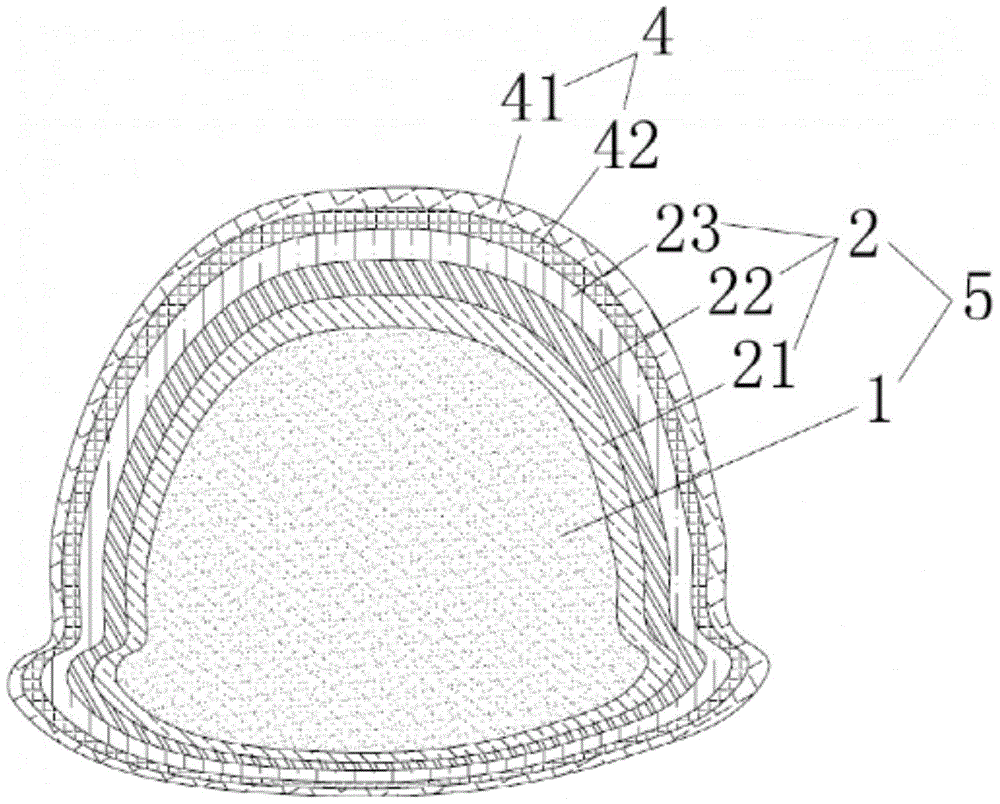

Manufacturing method of fully-reflective safety helmet

InactiveCN104544687AReflective in all directionsServe as a safety warningHatsHeadwear capsLight reflectionEngineering

The invention provides a manufacturing method of a fully-reflective safety helmet and belongs to the technical field of light reflection. The manufacturing method comprises the following steps: preparing a safety helmet molded after pressing a film and a fully-reflective PET film molded by vacuum suction; fixing the prepared fully-reflective PET film on the safety helmet through the vacuum suction of a vacuum suction machine to form the fully-reflective safety helmet, wherein vacuum suction is carried out at the temperature of 180-200DEG C under the pressure of 1kgf-3kgf for 10-20s; preparing a PET colored film molded by vacuum suction or a low-density PET film printed with patterns, and fixing the PET colored film or the low-density PET film printed with the patterns on the fully-reflective safety helmet through the vacuum suction of the vacuum suction machine to make a finished product. The fully-reflective safety helmet has the advantages of all-dimensional reflecting and no reflecting dead corners, has remarkable reflecting effect, performs a safety warning function on passers-by and drivers to an utmost extent, is reliable in the manufacturing method, high in manufacturing efficiency, firm in structure, long in service life and high in market competitiveness and can be used for a long term.

Owner:徐君东 +2

An anti-siphon sprue basin and method of making and using the same

ActiveCN112024826BForm a barrierReduce air entrainment and slag defectsFoundry mouldsFoundry coresWater trapAir entrainment

The invention relates to a sprue basin, provides an anti-siphon sprue basin and its manufacture and use, which overcomes the problems of quality defects such as slag inclusion and pores in castings that are easily attracted by the sprue basin. Mouth basin sand box, gate plug, sprue basin metal liquid holding room, sprue socket and anti-siphon dam; the outermost layer of the anti-siphon sprue basin is the sprue basin sand box, and the sprue basin metal liquid is arranged inside In the accommodating room, the bottom of the sprue pot sand box is provided with a sprue socket, and an anti-siphon dam is connected to the sprue socket. The anti-siphon sprue basin realizes no siphon phenomenon during the pouring process of the sprue basin, prevents the generation of vortices, reduces the slag inclusion and air entrainment of the product, reduces the defect of slag inclusion pores, and reduces the entrainment of air, scum, and molten slag into the cavity. Conducive to the guarantee of molten iron quality and improve the product quality of castings. Meanwhile, the manufacturing method is simple, reliable and effective, and the manufacturing cost is low.

Owner:KOCEL EQUIP

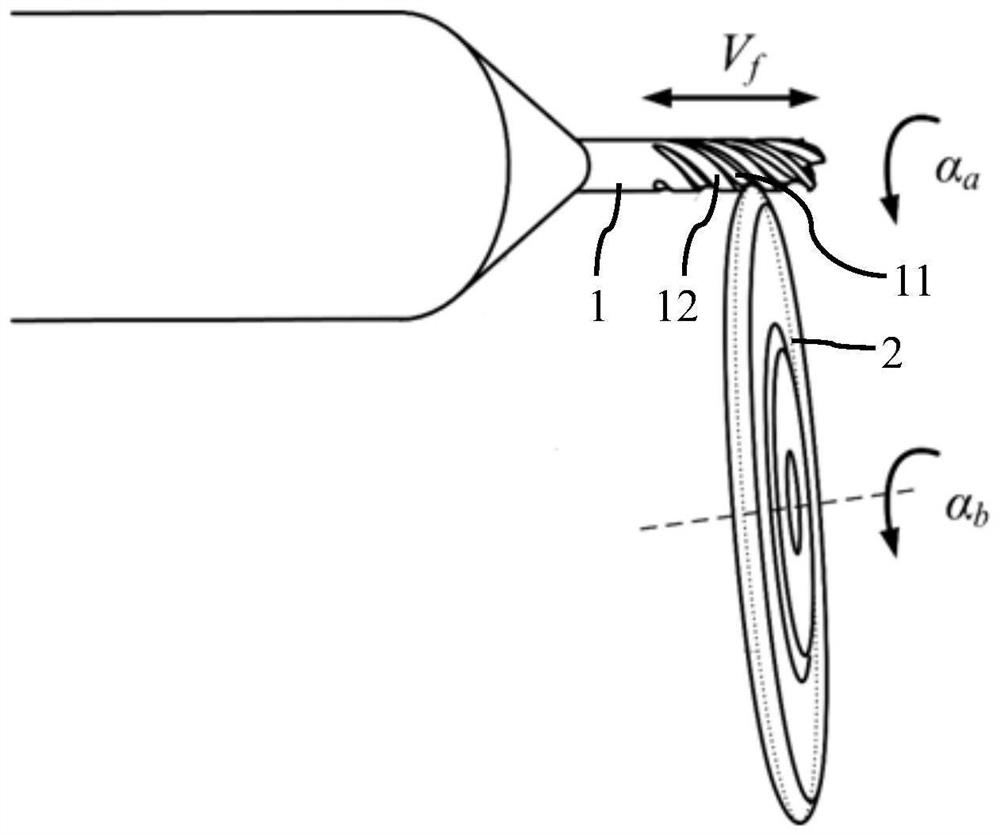

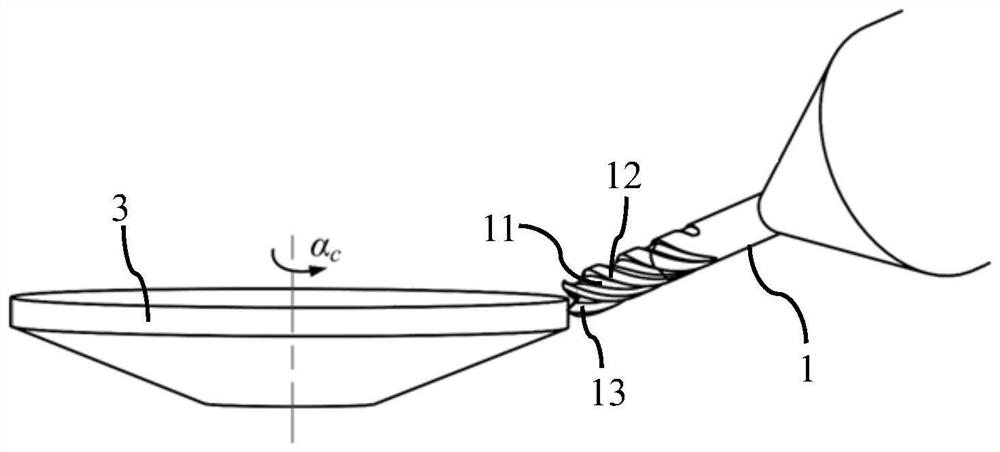

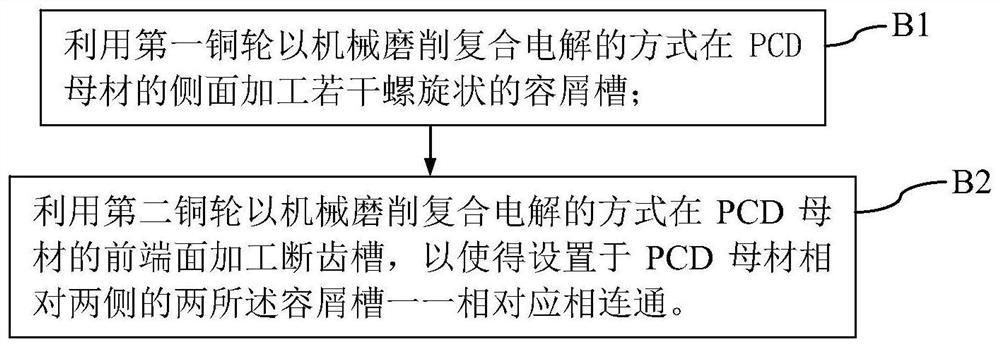

A method for manufacturing a one-piece pcd milling cutter head

The invention relates to the technical field of precision machining, and discloses a method for manufacturing a one-piece PCD milling cutter head, which includes the following steps: using the first copper wheel to process several Helical chip flutes, the cutting edge is defined between two adjacent chip flutes; the second copper wheel is used to process the broken tooth groove on the front end of the PCD base material in a mechanical grinding and electrolytic way, so that the setting The two chip pockets on the opposite sides of the PCD base material are in communication with each other correspondingly. The beneficial effects of the present invention are: high processing efficiency, the surface quality of the forming surface can be effectively improved by adjusting the processing parameters of electric discharge, and the cost is relatively low, the processing method is reliable, and the stability of the one-piece PCD milling cutter head can be guaranteed .

Owner:SHENZHEN UNIV +1

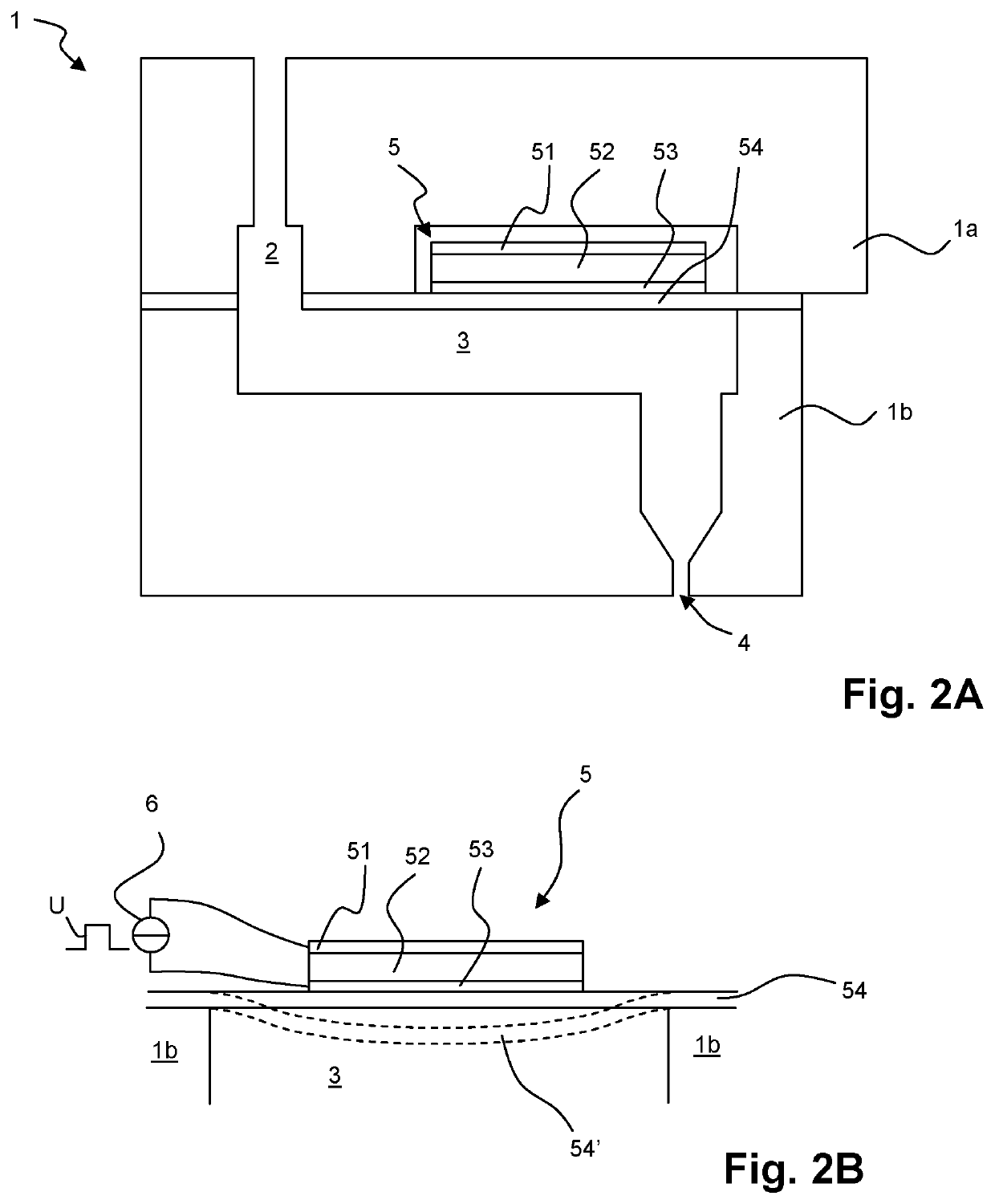

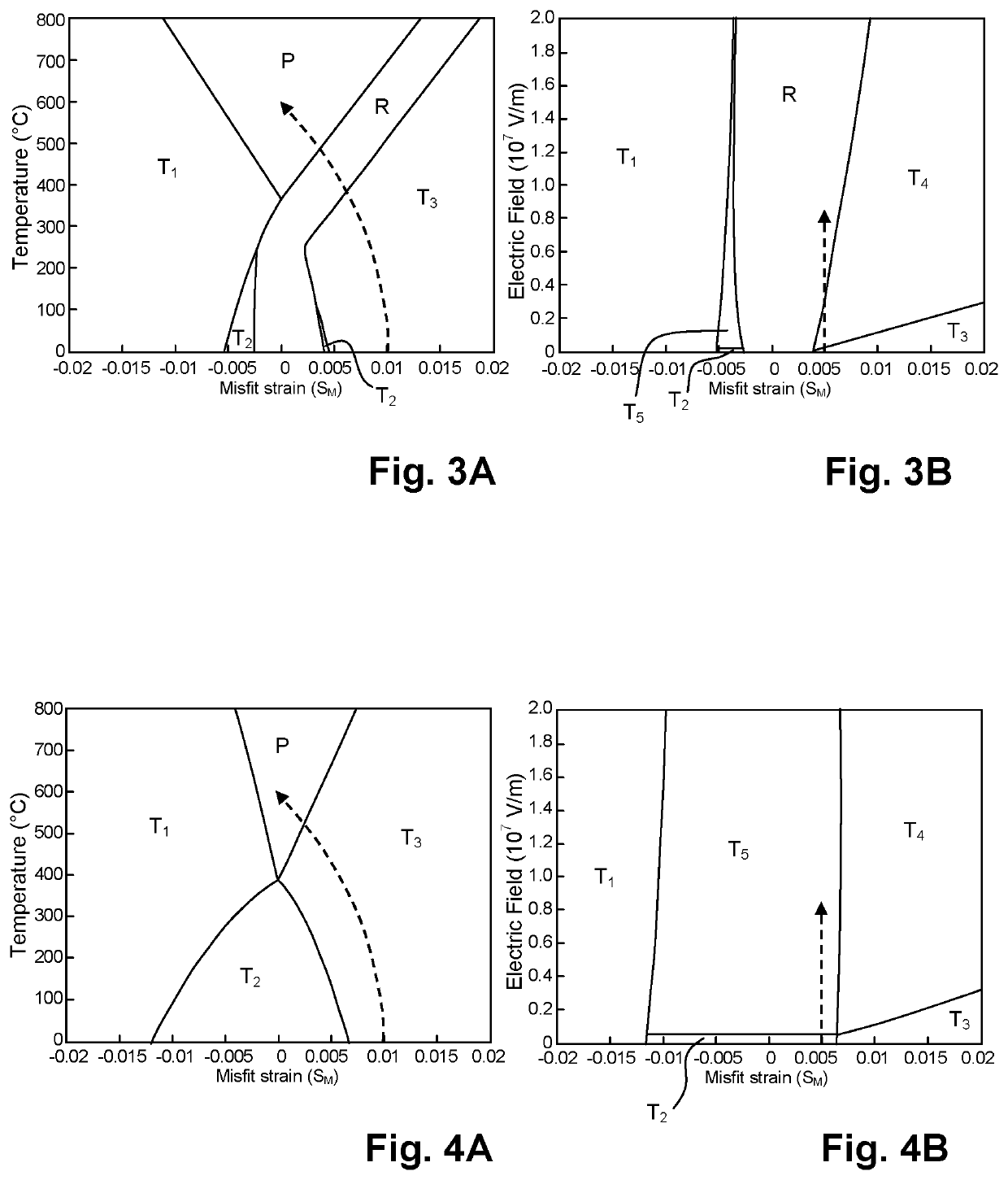

Method of manufacturing an inkjet print head and an inkjet print head with induced crystal phase change actuation

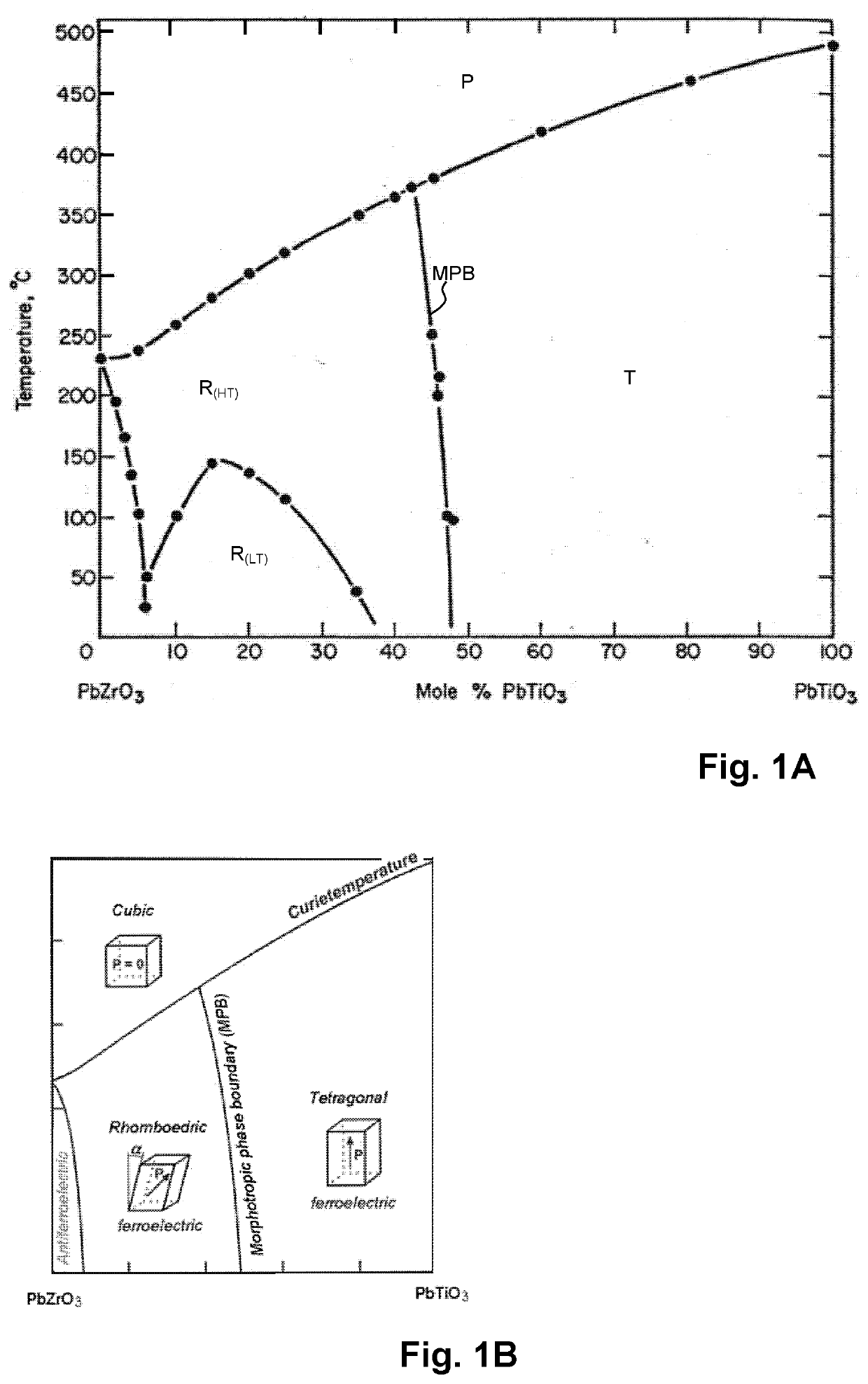

ActiveUS20200111947A1Reliable manufacturing methodReliable and controllablePiezoelectric/electrostrictive device manufacture/assemblyPrintingPiezoelectric actuatorsMechanical engineering

A method for manufacturing an inkjet print head includes determining a misfit strain—electric field crystal phase relation for at least one composition of a piezoelectric material; selecting a misfit strain value and a composition of the piezoelectric material based on the determined misfit strain—electric field crystal phase relation for said at least one composition; and based on the selected misfit strain and the selected composition of the piezoelectric material, forming a base layer and an actuator stack on the base layer, the actuator stack including the piezoelectric material, wherein the base layer and the actuator stack have predetermined properties providing the selected misfit strain value and the selected composition. Thus, an inkjet print head having a piezoelectric actuator that is operated on the basis of a crystal phase change is reliably manufacturable.

Owner:CANON PRODN PRINTING HLDG BV

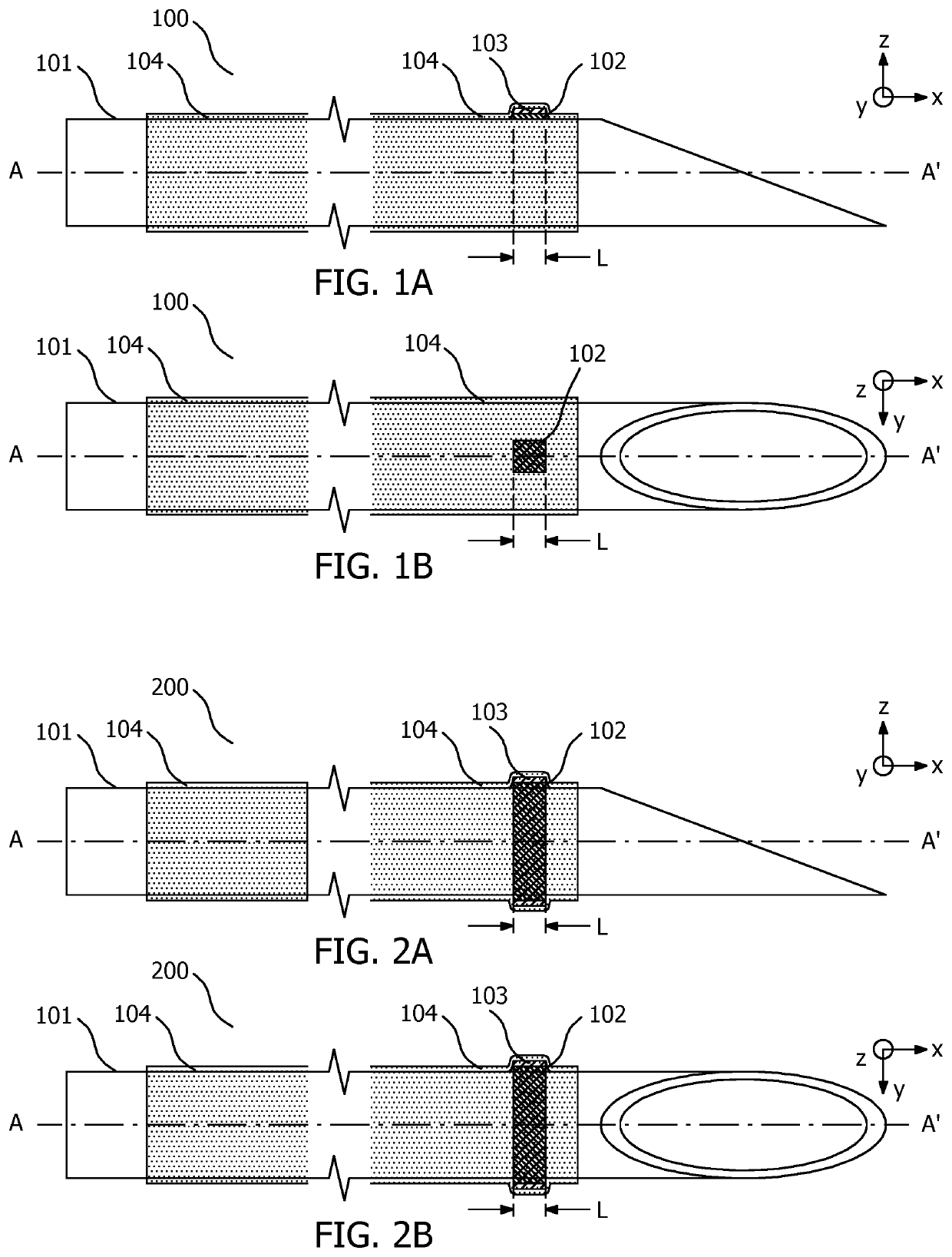

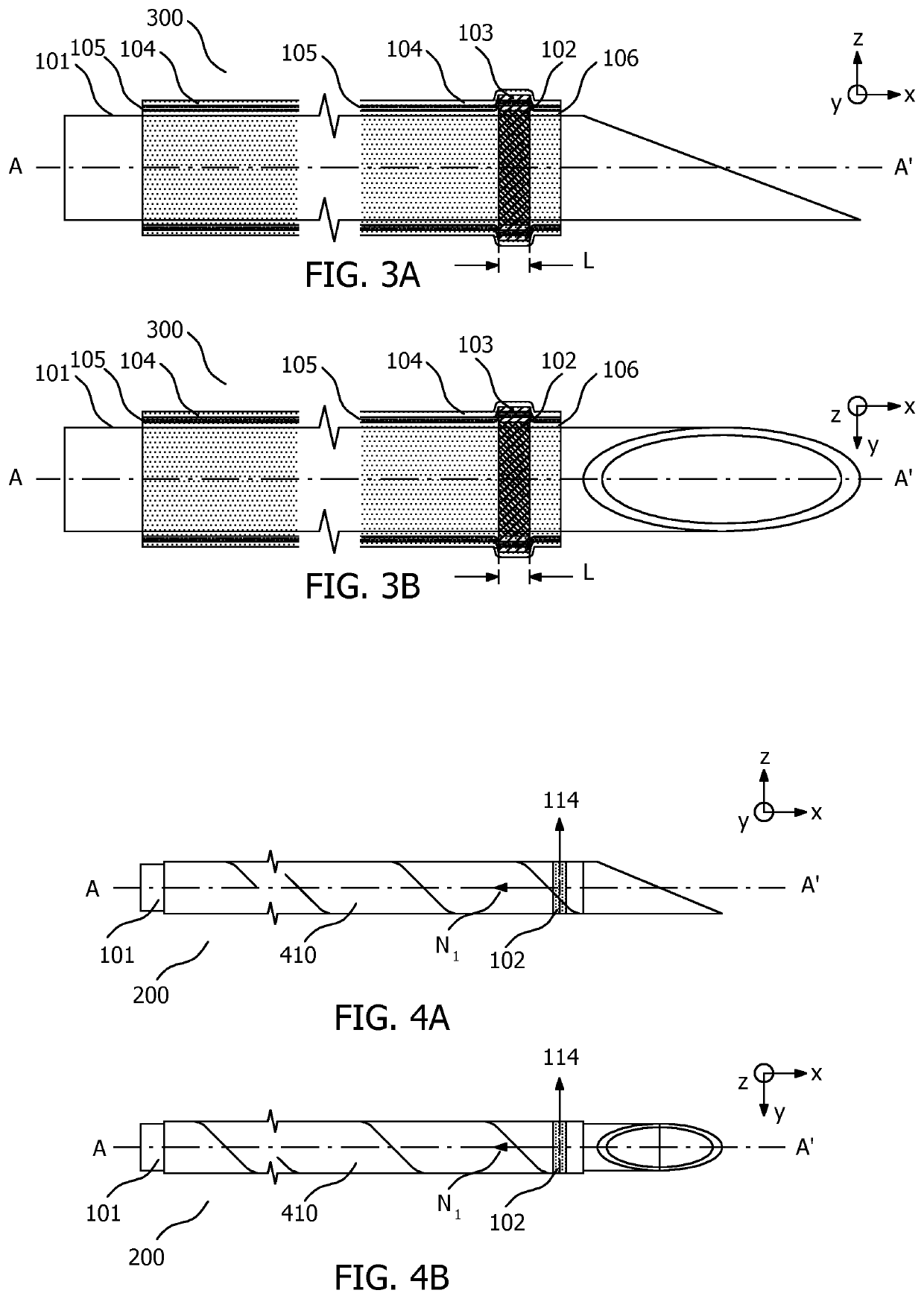

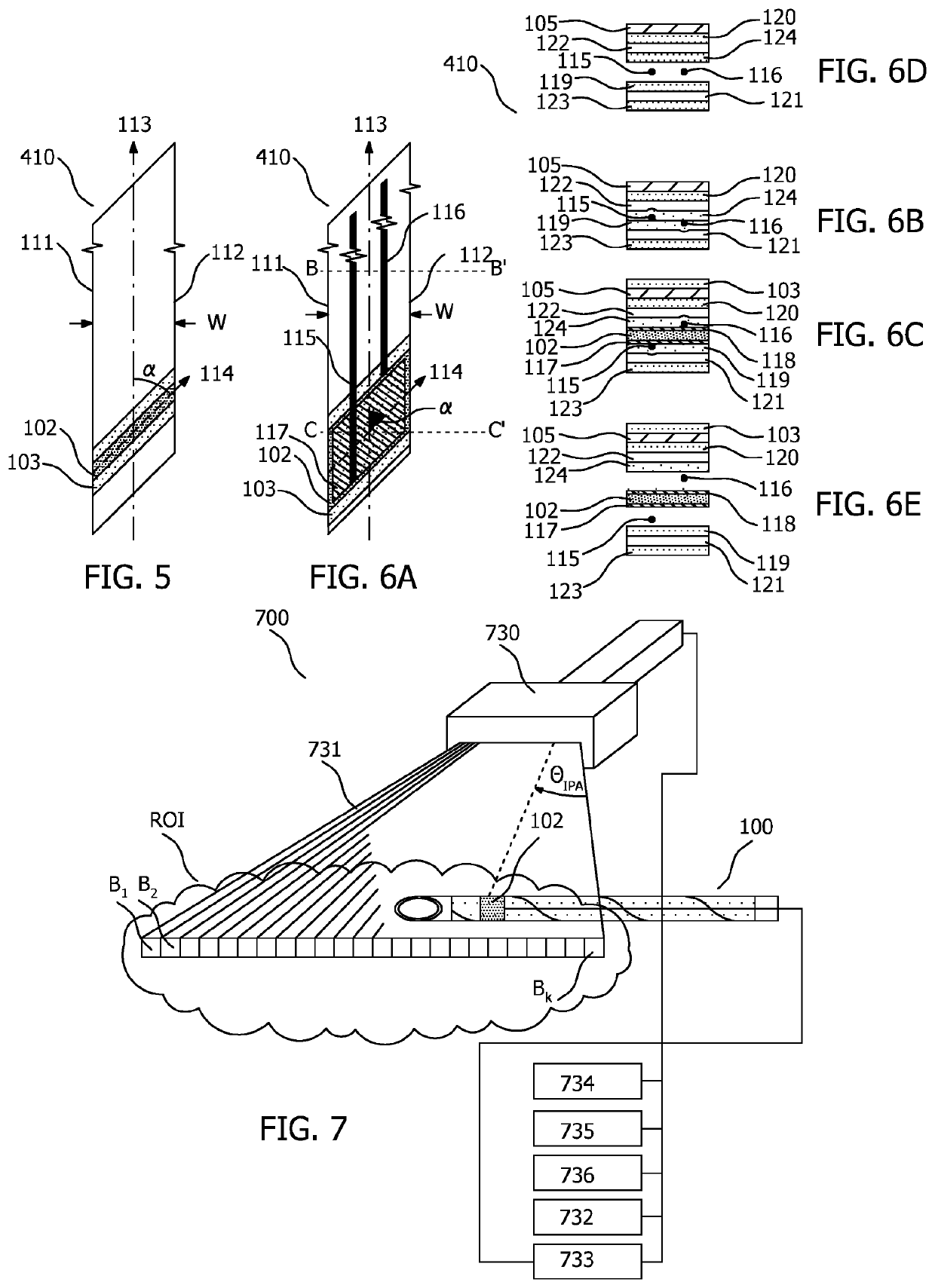

Interventional device with an ultrasound transducer

PendingUS20210307716A1Reduce decreaseSmoother topologyPiezoelectric/electrostrictive device manufacture/assemblyOrgan movement/changes detectionUltrasonic sensorBiomedical engineering

An interventional device (100, 200, 300) includes an elongate shaft (101) having a longitudinal axis A-A′, an ultrasound transducer (102), an adhesive layer (103), and a protective tube (104) formed from a protective tube (104) formed from a heat-shrink material. The ultrasound transducer (102) is disposed on the elongate shaft (101) such that the ultrasound transducer (102) has an axial extent L along the longitudinal axis A-A′, At least along the axial extent L of the adhesive layer (103) is disposed between the ultrasound transducer (102) and the protective tube (104) surrounds the ultrasound transducer (102) and the adhesive layer (103) is disposed between the ultrasound transducer (102) and the protective tube (104).

Owner:B BRAUN MELSUNGEN AG +1

High strength ultrafine fiber simulation composite lether and its manufacturing method

InactiveCN1308539CHigh tensile strengthHigh tear strengthTextiles and paperPolymer scienceNonwoven fabric

The present ivnention relates to a high-strength ultrafine fibre imitation leather. It is made up by using sea-island ultrafine fibre base cloth through processes of impregnating with polyurethane, extracting treatment and after-finishing. The described base cloth is a double-layer or more than double-layer composite base cloth formed from sea-island composite fibre woven fabric and non-woven fabric which are combined together by means of needling process or cohesive process, then said invention makes the composite base cloth undergo the processes of impregnating with polyurethane, hardening, extracting 'sea' component in the solvent capable of removing 'sea' component from sea-island fibre to obtain semifinished product, widening forming, mellowing, dyeing, grinding or sticking film so as to obtain the invented product.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Low-detonation velocity anfo explosive and preparation method thereof

ActiveCN101844956BImprove mixing uniformitySimple production processExplosivesParaffin waxMicrosphere

The invention relates to a low-detonation velocity anfo explosive and a preparation method thereof. The low-detonation velocity anfo explosive comprises 77-88 parts of modified powdery anfo explosive, 10-20 parts of porous granulated ammonium nitrate and 2-3 parts of polystyrene foam plastic microballoon, wherein the modified powdery anfo explosive mainly comprises 74.54-84.66 parts of crystallized ammonium nitrate, 0.15-0.26 part of modifying agent and 2.31-3.08 parts of compound oil phase; and the compound oil phase comprises 1.71-2.12 parts of paraffin, 0.58-0.86 part of rosin and 0.02-0.06 part of Span 80 emulsifying agent. The preparation method comprises the following steps of: mixing the crystallized ammonium nitrate and the modifying agent, crushing and drying; and then mixing with the compound oil phase; finally adding the porous granulated ammonium nitrate and the polystyrene foam plastic microballoon and uniformly mixing to obtain the low-detonation velocity anfo explosive with the density less than 0.55g / cm<3> and the detonation speed less than 2,600m / s. The explosive has the advantages of favorable particle flowability, convenience for filling into a blast hole, low detonation velocity, low density and capability of meeting the requirements for using the explosive on smooth surface blasting and presplitting blasting of mines, highways, railways and open-air deep-hole slopes.

Owner:HUAINAN SHUNTAI CHEM

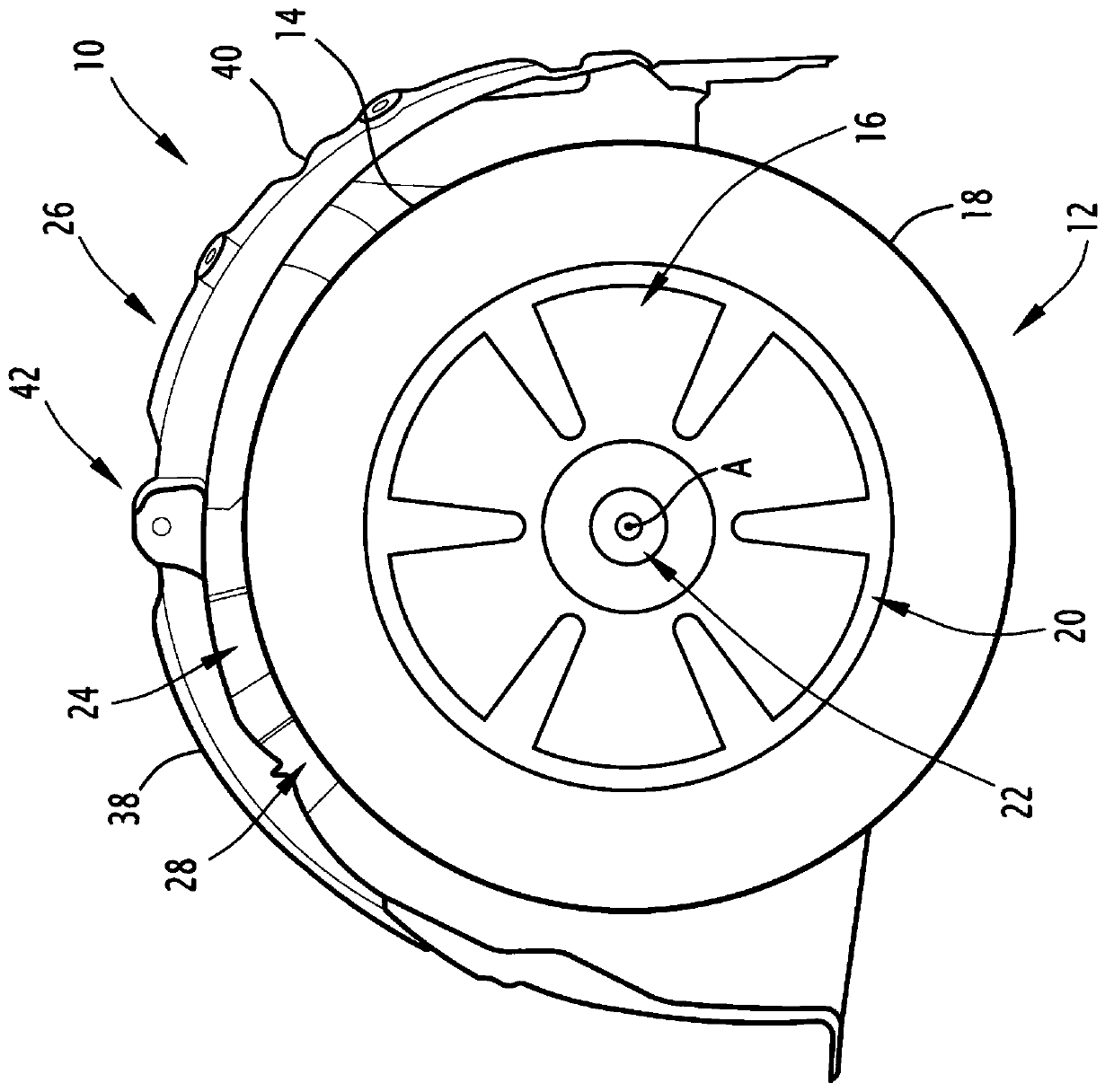

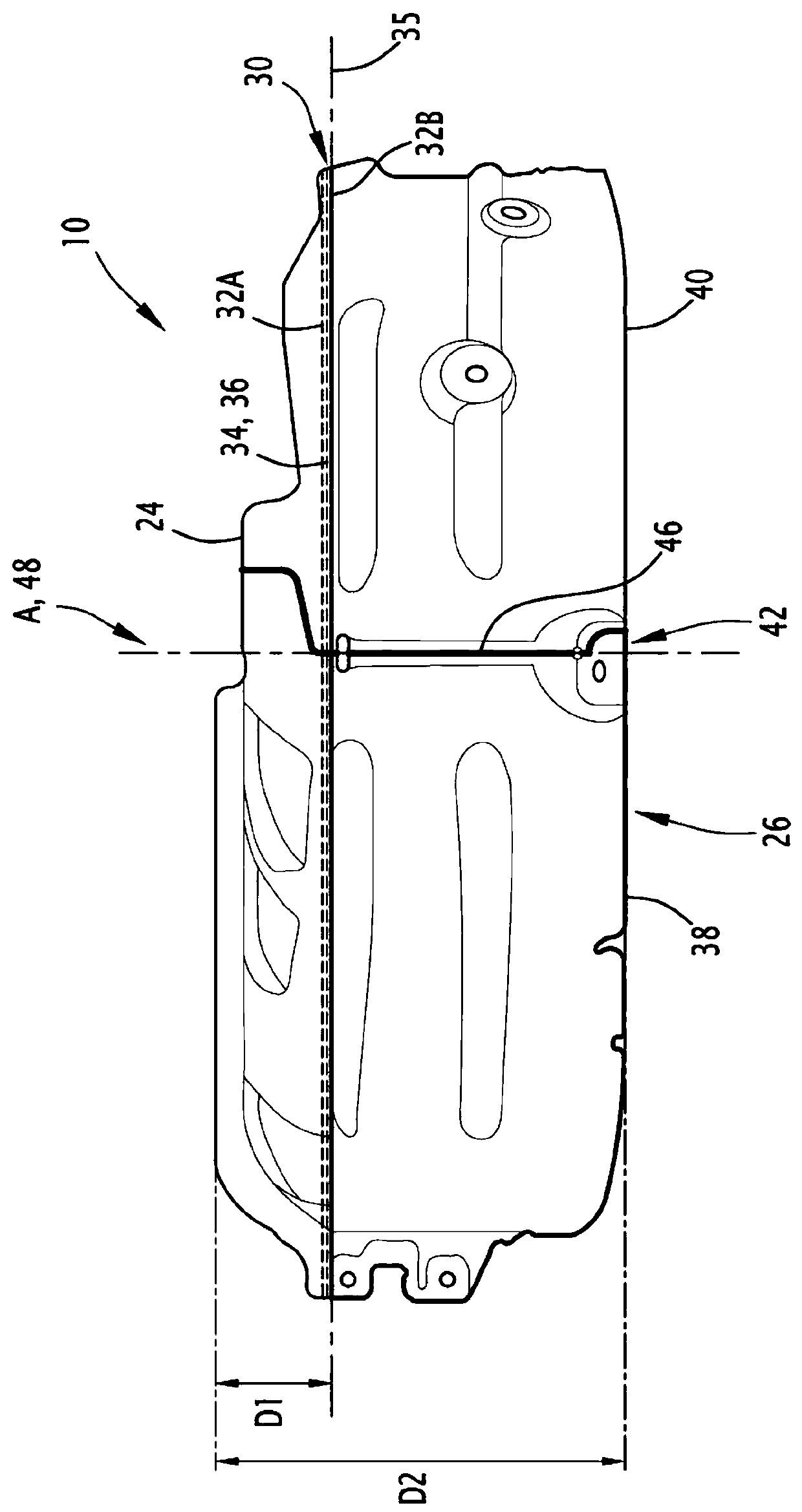

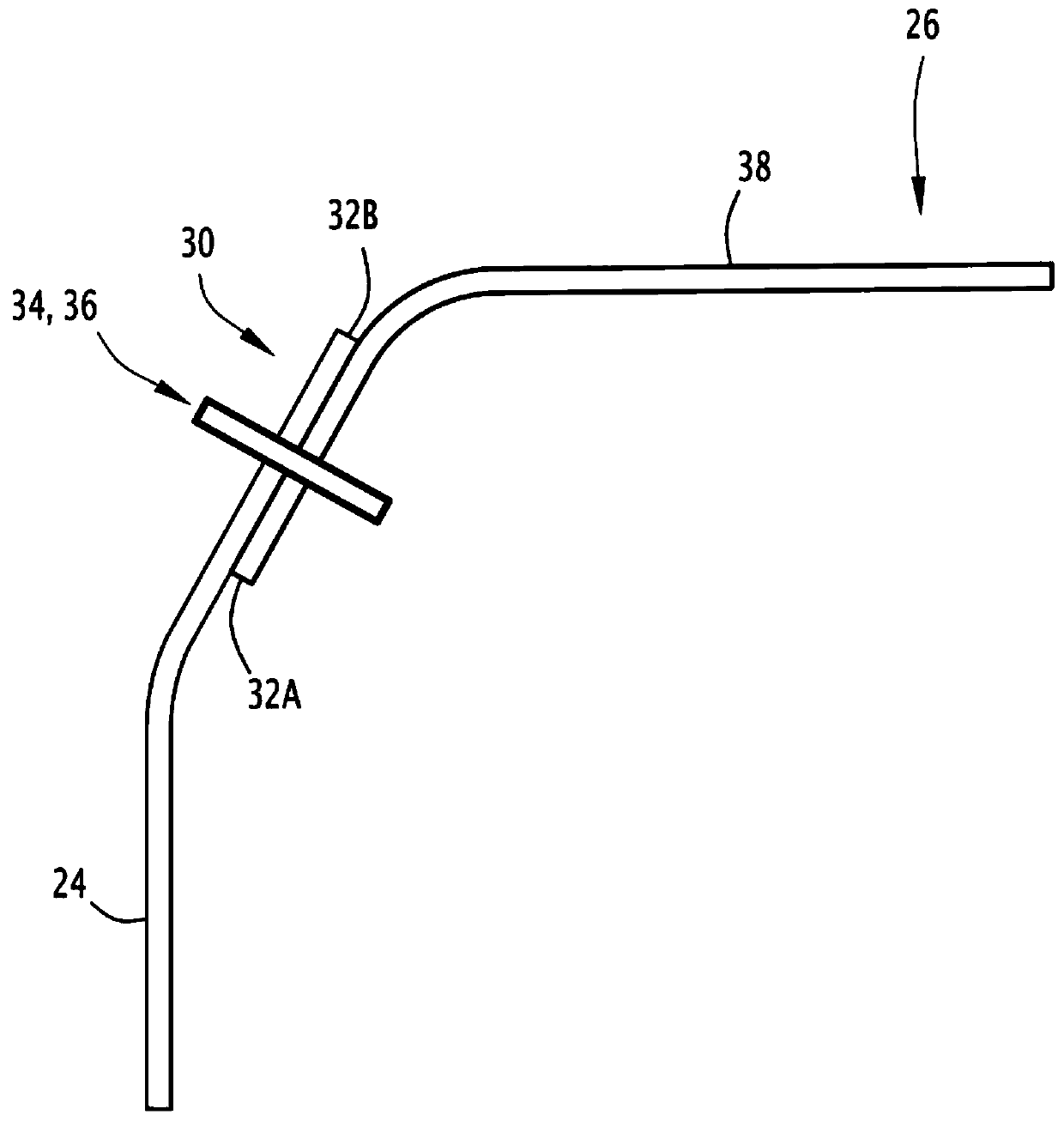

Associated wheel arch housing, vehicle, essential portion and manufacturing method

ActiveCN111098935ALimit lossReliable manufacturing methodSuperstructure subunitsStructural engineeringMotorized vehicle

Owner:FAURECIA AUTOMOTIVE IND

A microwave multi-chip packaging structure utilizing through-silicon vias and its manufacturing method

ActiveCN102723306BReduce lossIncrease packing densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSystem in package

The invention provides a microwave multi-chip packaging structure using a silicon through hole and a manufacture method thereof. The method uses a temperature safety valve (TSV) to achieve two-sided integrated system-stage packaging structure, when a monolithic microwave integrated circuit (MMIC) chip needs integrating, a user does not need embed a substrate before wiring, and performance, reliability and rate of finished products of the packaging structure are improved. Simultaneously, processes such as injection, corrosion, release and high temperature annealing in a manufacture process can be used before integration of the MMIC, and components needing special processes can be assembled and integrated in advance on the other side of the substrate. Therefore, the substrate comprising active and passive devices, micro-electromechanical systems (MEMS), photoelectric devices and the like can be conveniently manufactured in a large scale before integration of the MMIC, and the manufacture method is simple in process, reduces cost, and is advanced and reliable at present.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Edible mushroom foods and preparing method thereof

InactiveCN101317650BRegulate physiological functionImprove self-healing abilityMetabolism disorderDigestive systemBiotechnologySalvia miltiorrhiza

The invention relates to edible fungi food and a manufacture method thereof, in particular to an edible fungi food and the preparation method thereof. The raw material used by the invention is preciously edible and medicinal fungi ganoderma spore powder, aweto mycelia powder and fine cordyceps militaris powder, and wild termite mushroom, wild matsutake and wild golden mushroom, which are compounded with salvia miltiorrhiza, astragalus and Chinese medicinal material used for preparing polygonum with the function of health-caring and the action of cooperating. The preparation method can be seenin the specifications for detail. The edible fungi food of the invention has reasonable compounding by the edible fungi and the Chinese medicinal material which has health-caring function and can completely regulate the physiological function of body after being eaten; especially when people in sub-health state eat the edible fungi food, the non-normal physiological activation and the low physiological state can be recovered to a normal state, thus improving the health-recovery capability of the body and gradually recovering the health state. The preparation method of the invention is simple and reliable.

Owner:朱新锁

Fluorescent lamp producing method

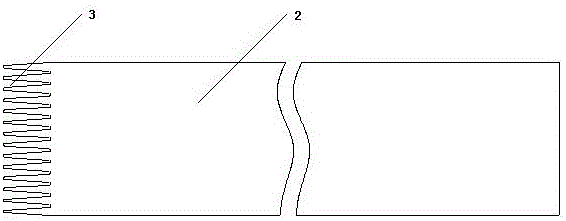

InactiveCN1251273CEasy to prepareReliable manufacturing methodTube/lamp screens manufactureTube/lamp vessels closingFront end of lineExhaust pipe

A fluorescent lamp is produced by substantially parallelly disposing, holding and fixing a pair of lead wires (3, 3) between a block-like holder and a block-like auxiliary holder (2), attaching an electrode (4) to the tips (3', 3') of the projecting lead wires (3, 3), disposing an exhaust pipe (6) with its opposite ends positioned outside an exhaust pipe receiving groove, inserting the electrode (4) and exhaust pipe (6) into the end of a glass tube (7), heating the glass tube adjacent its end to effect the heat pinch seal of the lead wires, thus integrating the glass tube and exhaust pipe, evacuating the glass tube through the exhaust pipe, removing the block-like holder and block-like auxiliary holder, heat-sealing the tip of the glass tube , and cutting away the exhaust pipe. It is possible to provide a fluorescent lamp producing method that is simple, reliable and stable, with nothing but the electrode existing between the lead wires.

Owner:PANASONIC CORP

A kind of manufacturing method of fully reflective safety helmet

InactiveCN104544687BReflective in all directionsServe as a safety warningHatsHeadwear capsLight reflectionEngineering

The invention provides a manufacturing method of a fully-reflective safety helmet and belongs to the technical field of light reflection. The manufacturing method comprises the following steps: preparing a safety helmet molded after pressing a film and a fully-reflective PET film molded by vacuum suction; fixing the prepared fully-reflective PET film on the safety helmet through the vacuum suction of a vacuum suction machine to form the fully-reflective safety helmet, wherein vacuum suction is carried out at the temperature of 180-200DEG C under the pressure of 1kgf-3kgf for 10-20s; preparing a PET colored film molded by vacuum suction or a low-density PET film printed with patterns, and fixing the PET colored film or the low-density PET film printed with the patterns on the fully-reflective safety helmet through the vacuum suction of the vacuum suction machine to make a finished product. The fully-reflective safety helmet has the advantages of all-dimensional reflecting and no reflecting dead corners, has remarkable reflecting effect, performs a safety warning function on passers-by and drivers to an utmost extent, is reliable in the manufacturing method, high in manufacturing efficiency, firm in structure, long in service life and high in market competitiveness and can be used for a long term.

Owner:徐君东 +2

A kind of preparation method of cualo2 powder that can be adapted to solar cell

InactiveCN103523815BHigh purityStrong transmittanceCopper compoundsPolyvinyl alcoholPhotoluminescence

The invention discloses a preparing method of CuAlO2 powder adaptable to a solar cell. The method comprises the steps of placing cuprous oxide and aluminum hydroxide into polyvinyl alcohol with a weight ratio of 1:1-4, and carrying out magnetic stirring at the indoor temperature till the two components are fully dissolved to obtain two kinds of sol, wherein the polyvinyl alcohol accounts for 64-78% of the total content; mixing the two kinds of sol and then carrying out magnetic stirring to obtain precursor sol; drying the obtained precursor sol at the temperature of 135-175 DEG C to obtain one kind of dry sol; porphyrizing the obtained dry sol in an agate mortar and then placing the porphyrized dry sol into a sintering furnace to obtain the CuAlO2 powder after annealing. According to the preparing method of the CuAlO2 powder adaptable to the solar cell, pattern analysis, photoluminescence analysis and infrared spectroscopy analysis are carried out on the solution and sinter to confirm that a generated sample is high in purity and high in transmittance, especially infrared light transmittance. Therefore, the preparing method of the CuAlO2 powder adaptable to the solar cell also has a good application prospect in the field of manufacturing of optical devices.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Explosion welding explosive with low explosion velocity

InactiveCN101602636BImprove mixing uniformitySimple production processExplosivesNon-electric welding apparatusWaxTEX-explosive

The invention discloses an explosion welding explosive with a low explosion velocity for explosion welding between metal sheet materials and preparation method thereof. The explosion welding explosive consists of 66 to 76 portions of ammonium nitrate, 3 to 5 portions of composite oil phase and 21 to 29 portions of doped powder, wherein the composite oil phase consists of 2.6 to 4.8 portions of solid wax and 0.2 to 0.4 portion of stearic amine salt; and the doped powder consists of 15.95 to 23.2 portions of ferric oxide powder and 5.04 to 8.9 portions of diatomite powder. The preparation method comprises the following steps: adding water with 8 to 12 mass percent of the ammonium nitrate into the ammonium nitrate; heating and dissolving the mixture to obtain aqueous solution of ammonium nitrate; under low-speed stirring, dispersing the composite oil phase and the doped powder respectively into the aqueous solution of the ammonium nitrate; mixing and heating the mixed solution till a temperature of between 105 and 125 DEG C to obtain suspended mixed solution; removing moisture in a vacuum tank with vacuum degree of between 0.07 below zero and 0.09 MPa below zero; and cooling, sievingand filling the explosive to obtain the explosion welding explosive with the low explosion velocity of less than 2,400 m / s. Explosive particles have good dispersion and are convenient to distribute;and the explosive has low explosion velocity and stable explosion performance and can meet the requirement of the explosive for the explosion welding of different metal materials.

Owner:黄文尧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com