An anti-siphon sprue basin and method of making and using the same

A sprue basin and anti-siphon technology, which is applied to manufacturing tools, casting molding equipment, casting mold components, etc., can solve the problems of casting slag inclusion and stomata defects, air-entrained slag defects, and easy occurrence of siphon effect, and the method is reliable. Effective, reducing the defects of entrained air and slag, and the effect of simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

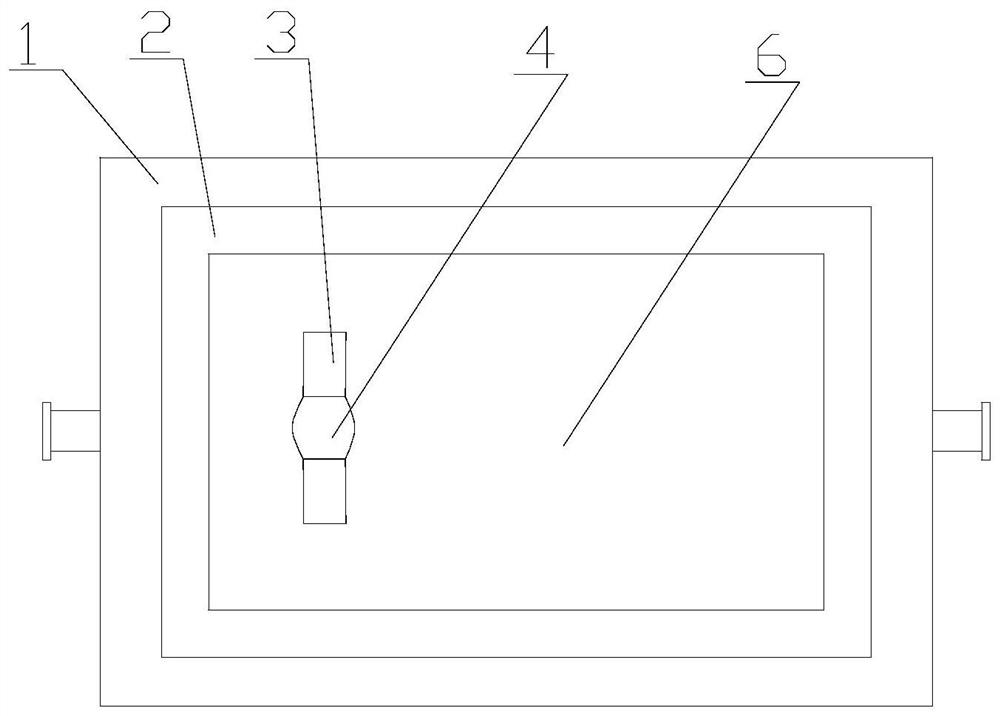

[0029] An anti-siphon sprue basin, such as Figure 1-Figure 3 , including the sprue basin sand box 1, the sprue basin metal liquid holding room 6, the gate plug 11, the sprue socket 4 and the anti-siphon dam 3.

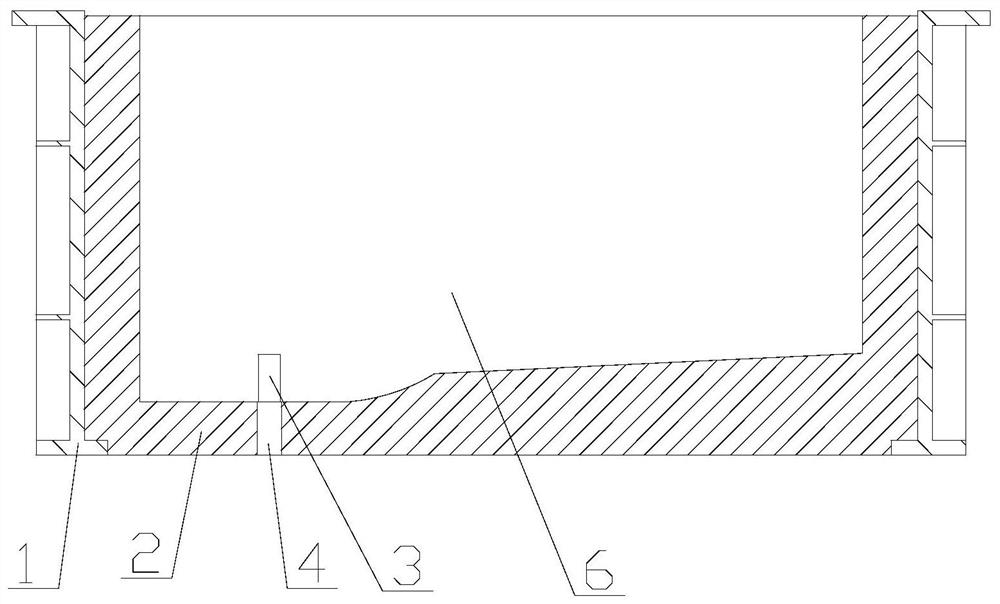

[0030] The outermost layer of the anti-siphon sprue pot is the sprue pot sand box 1, the sprue pot sand box 1 is a hollow box body, and a sprue pot metal liquid accommodating chamber 6 is formed in the pot, and the bottom of the sprue pot sand box 1 is provided with There is a sprue socket 4 and an anti-siphon dam 3 is connected to the upper part.

[0031] Further, the sprue pot flask 1 is made by casting, and hangers are designed on the left and right outer walls of the sprue pot flask 1 .

[0032] Further, the anti-siphon dam is made of refractory materials, and its size is: the height is 1.5 times the diameter of the sprue; the width is 1.0 times the diameter of the sprue, and the thickness is 0.5 times the diameter of the sprue .

[0033] Further, the sprue soc...

Embodiment 2

[0035] A method for making an anti-siphon sprue basin, comprising the following steps:

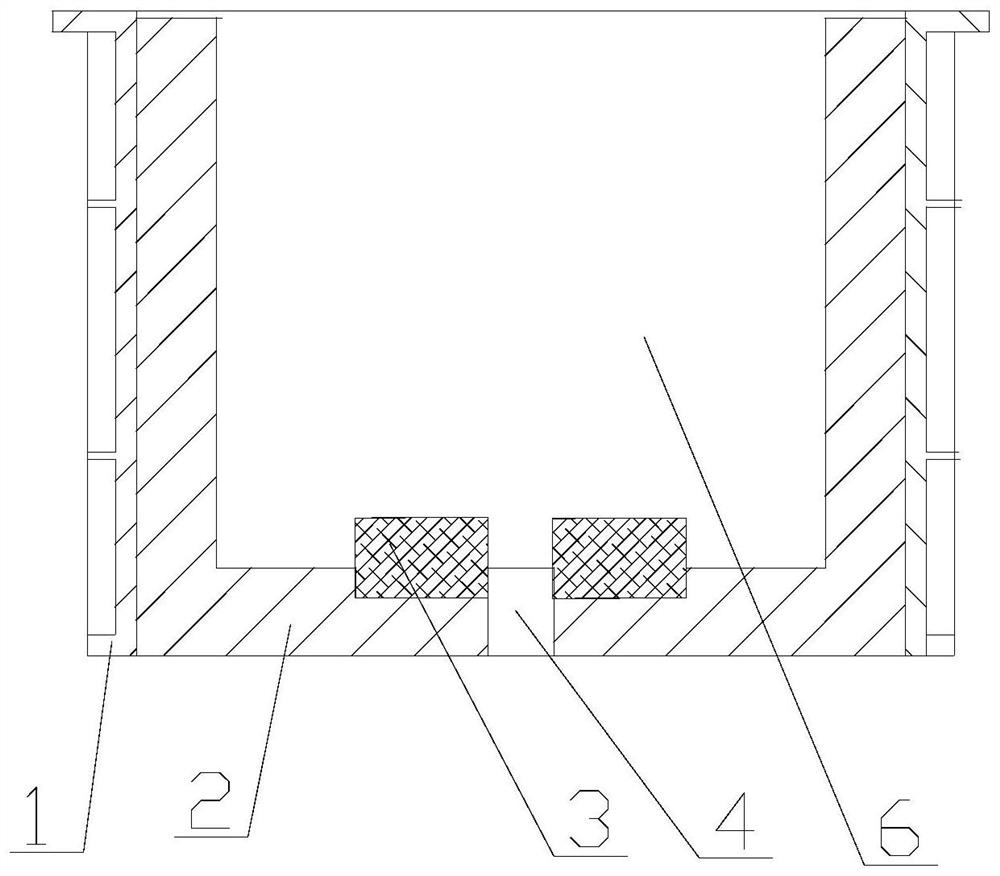

[0036] The anti-siphon sprue basin mould 5 is pre-designed, the shape of the anti-siphon sprue basin mould 5 is the same as the shape of the sprue basin accommodating chamber 6, and the siphon dam positioning hole 7 is reserved on the mould for placing the refractory dam forming the anti-siphon dam 3 material, and leave a 2mm gap at the 7 position of the siphon dam positioning hole to facilitate the placement of the refractory anti-siphon dam refractory material;

[0037] After making the designed mold, place the sprue pot mold 5 in a suitable position in the sand box, and place the sprue nest refractory porcelain tank and the refractory anti-siphon dam.

[0038] Fill the mixed resin sand 2 into the gap between the sand box and the mold, and keep vibrating to ensure the filling density;

[0039] After the resin is hardened, the sprue pot sand box formed by the sand box and the resin sand ...

Embodiment 3

[0042] An anti-siphon sprue basin, its use method is as follows:

[0043] When casting castings, lead the sprue 10 to the upper box surface, and fully tighten it to ensure the strength of the molding sand;

[0044] When closing the box, place a circle of refractory mud along the sprue on the upper surface of the mold, and then place the sprue basin to ensure that the center of the sprue nest 4 of the sprue basin is aligned with the center of the sprue, and then place the sprue nest in the sprue nest. Place the gate plug 11 in 4 and seal it so that the molten metal cannot enter the mold in advance;

[0045] When pouring, start pouring after the casting liquid is smelted qualified. After pouring to more than 2 / 3 of the nozzle basin, pull out the gate plug 11, and the molten metal enters the cavity through the sprue to complete the casting of the casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com