A kind of macromolecule retarder, its preparation method and application

A retarder and macromolecular technology, which is applied in the field of building material admixtures, can solve problems such as short retardation time and reduced concrete strength, and achieve the effects of avoiding adsorption and easy detachment, low production cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

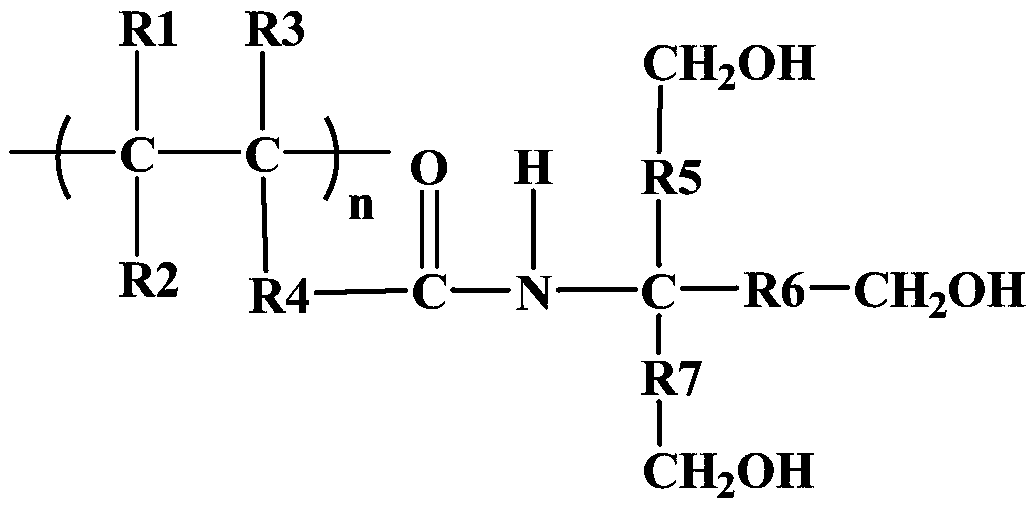

[0025] The invention provides a kind of preparation method of macromolecule retarder, comprises the following steps:

[0026] Step S1, performing free radical polymerization on small unsaturated monomers containing epoxy groups to prepare intermediates;

[0027] Step S2, reacting the intermediate with an amino group-containing methylol compound to prepare a macromolecular retarder.

[0028] The present invention first utilizes free radical polymerization to polymerize the unsaturated small monomers containing epoxy groups to form the intermediates containing epoxy groups with a certain degree of polymerization. The free radical polymerization is carried out under stirring and under condensing conditions.

[0029] The solvent used in the radical polymerization reaction is a polar organic solvent miscible with water, and N,N-dimethylformamide or N-alkylpyrrolidone is preferably used in the present invention.

[0030] The initiator used in the radical polymerization reaction is...

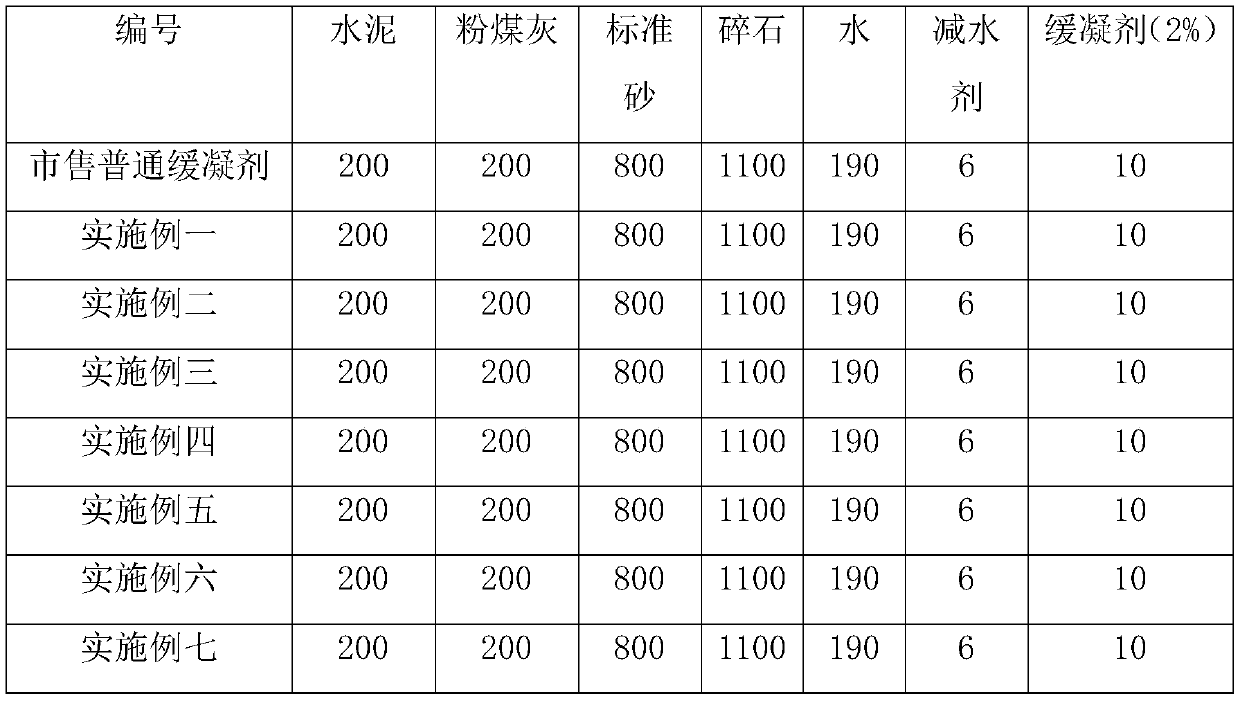

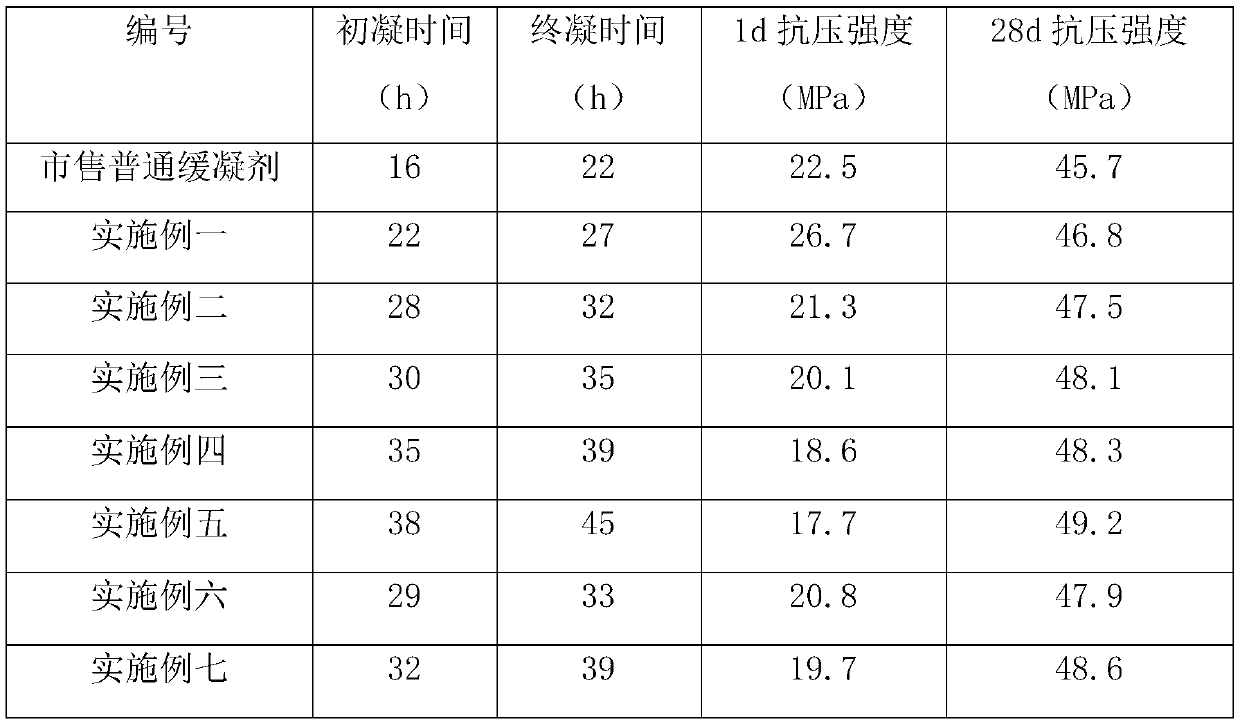

Embodiment 1

[0041] 1.1 Weigh 50g of glycidyl acrylate, 0.25g of benzoyl peroxide, and 200g of N,N-dimethylformamide into a three-necked bottle, install a stirring device, a thermometer and a condenser, heat up to 80°C, and React at this temperature for 10 hours, then lower to normal temperature (25°C), to obtain an intermediate with an average degree of polymerization of about 10;

[0042] 1.2 Add 46g of tris to the intermediate obtained in step 1.1, and stir and react at room temperature (25°C) for 10 hours to obtain a macromolecule retarder;

[0043] 1.3 Add water to the macromolecular retarder obtained in step 1.2 to prepare the macromolecular retarder with a mass concentration of 40%.

Embodiment 2

[0045] 2.1 Weigh 50g of glycidyl acrylate, 0.2g of benzoyl peroxide, and 200g of N,N-dimethylformamide into a three-necked bottle, install a stirring device, a thermometer and a condenser, heat up to 90°C, and Reaction at this temperature for 8 hours, lowered to normal temperature (25°C), to obtain an intermediate with an average degree of polymerization of about 30;

[0046] 2.2 Add 46 g of tris to the intermediate obtained in step 2.1, and stir and react at room temperature (25° C.) for 11 hours to obtain a macromolecule retarder;

[0047] 2.3 Add water to the macromolecular retarder obtained in step 2.2 to prepare the macromolecular retarder with a mass concentration of 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com