A kind of molecular weight regulator for emulsion polymerization and preparation method thereof

A technology of molecular weight regulator and emulsion polymerization, which is applied in ether preparation, ester reaction preparation of ether, organic chemistry, etc. It can solve the problems of poor molecular weight adjustment ability, solubility drop, unfavorable environmental protection, etc., to increase the diffusion rate and facilitate the synthesis process , The effect of simple reaction mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

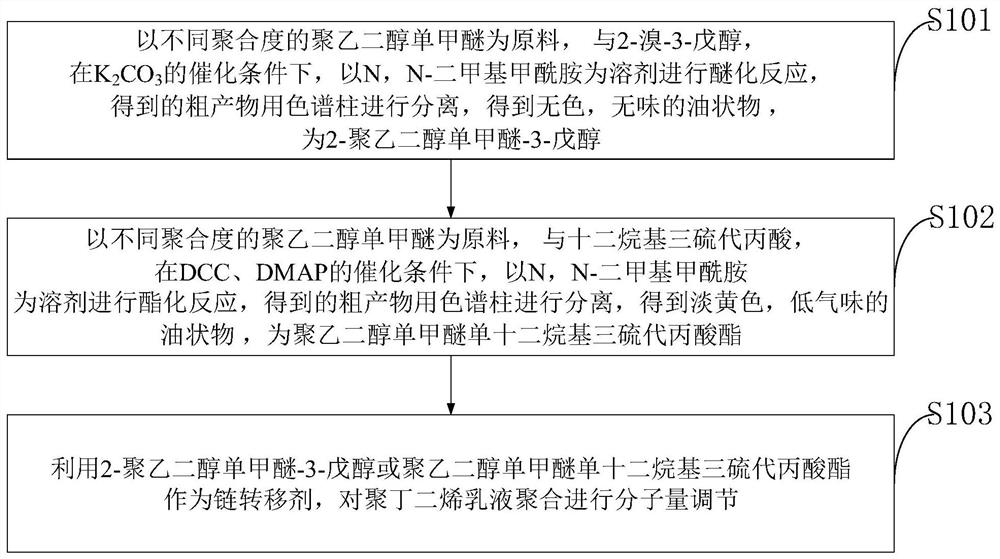

[0049] The preparation method of the molecular weight regulator for the emulsion polymerization that the embodiment of the present invention provides comprises:

[0050] Carry out Williamson etherification reaction of polyethylene glycol monomethyl ether and 2-bromo-3-pentanol in N,N-dimethylformamide solvent to obtain 2-polyethylene glycol monomethyl ether-3-pentanol crude Product, polyethylene glycol monomethyl ether and dodecyl trithiopropionic acid, with N, N-dimethylformamide as solvent, in dicyclohexylcarbodiimide (DCC) and 4-dimethyl A catalytic system composed of aminopyridine (DMAP) was used for esterification to obtain a crude product of polyethylene glycol monomethyl ether monododecyl trithiopropionate. The two crude products were separated and purified by column chromatography to obtain two Different types of low odor, all of them are molecular weight regulators with emulsifying function.

[0051] Specifically include:

[0052] In the presence of a catalyst, poly...

Embodiment 1

[0062] The preparation method of the tasteless, water-soluble and emulsifying molecular weight regulator provided by the embodiment of the present invention comprises the following steps:

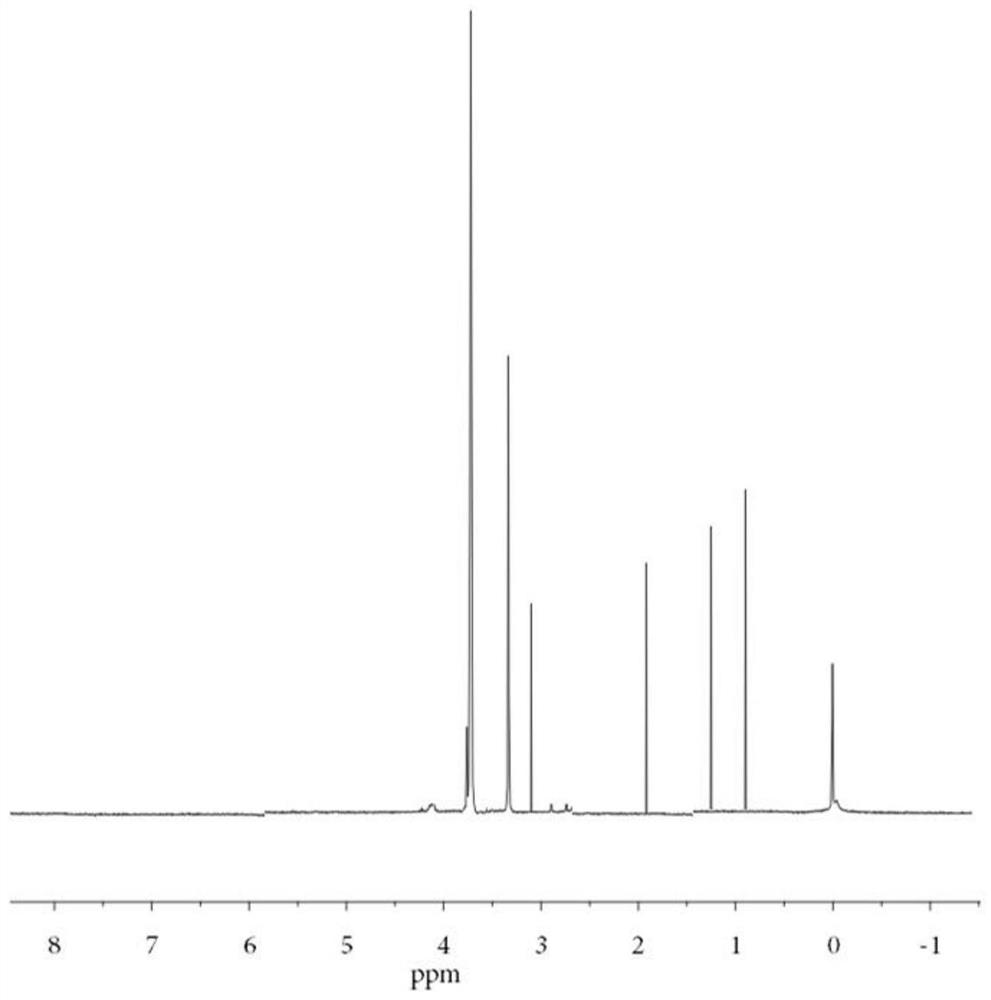

[0063] The first step is to use polyethylene glycol monomethyl ether with different degrees of polymerization as raw materials to carry out etherification reaction with 2-bromo-3-pentanol. The specific method is: a 1000mL three-neck round bottom flask is equipped with a dropping funnel , reflux condenser and magnetic stirring, add 500mL of N,N-dimethylformamide, then add polyethylene glycol monomethyl ether and 2-bromo-3-pentanol, react according to the amount of substances 1:1.5 , such as adding 190 grams of polyethylene glycol monomethyl ether with an average molecular weight of 1900, 25 grams of 2-bromo-3-pentanol, and adding 20.7 grams of anhydrous K 2 CO 3 Carry out catalysis, heat to 60-70°C and stir the reaction, and monitor the reaction by pointing the plate at any time. The reacti...

Embodiment 2

[0068] The preparation method of the low-odor, water-soluble and emulsifying molecular weight regulator provided by the embodiments of the present invention comprises the following steps:

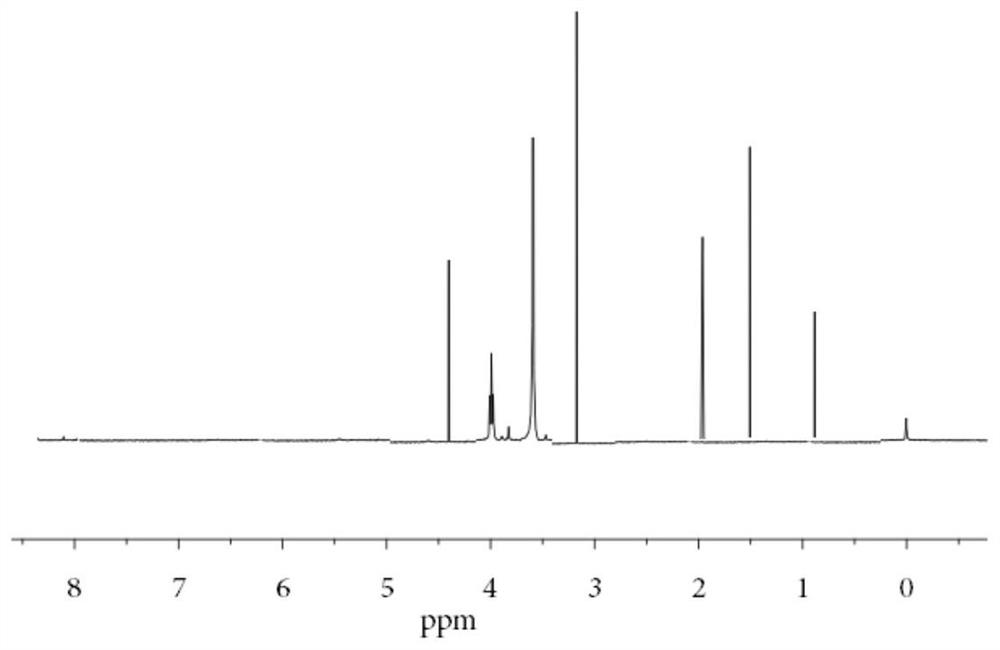

[0069] In the first step, add 35 grams of polyethylene glycol monomethyl ether with a molecular weight of 350 and 2-bromo-3-pentanol and 200 ml of N,N-dimethylformamide solvent into a 1000 ml reflux device In the three-necked flask, add 20.7 grams of anhydrous K 2 CO 3Carry out catalysis, heat to 65°C and stir the reaction, react for 6 hours, remove the solvent N,N-dimethylformamide by rotary evaporation, and use chromatographic column to separate and purify to obtain 2-polyethylene glycol monomethyl ether-3-pentanol Make chain transfer agent 3.

[0070] In the second step, 35 grams of polyethylene glycol monomethyl ether, 54.6 grams of dodecyl trithiopropionic acid and 200 ml of N,N-dimethylformamide solvent with a molecular weight of 350 are added to the reflux device In a 1000ml three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com