A method for electrocatalytic reduction dechlorination of wastewater containing chlorinated organic pollutants

A technology of organic pollutants and electrocatalysis, applied in the fields of water pollutants, chemical instruments and methods, water/sewage treatment, etc. Pollution, reduced reactivity of polymetallic systems, etc., to achieve the effect of treatment time period, high selectivity, and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

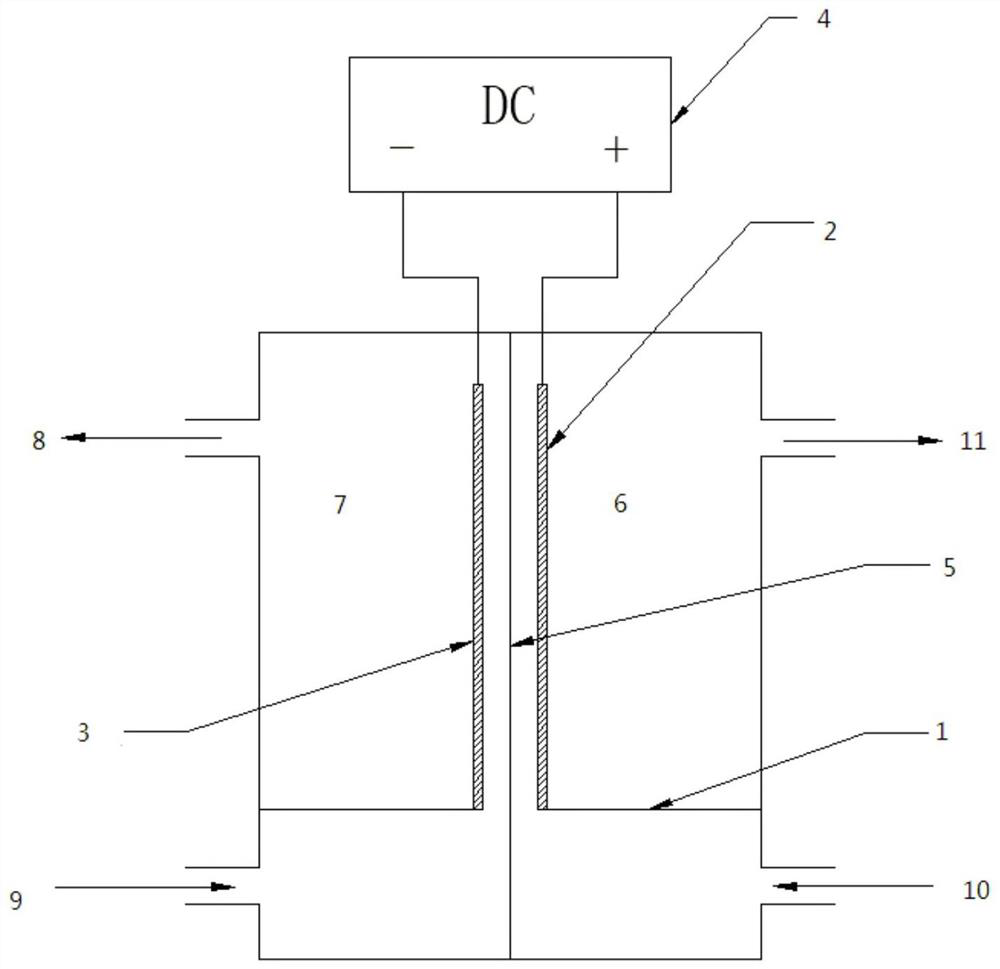

[0037] (1) if figure 1 Shown, will connect the graphite electrode 2 of power source 4 and the C-Pd-Ag / g-C that the present invention method prepares respectively 3 N 4 The composite electrode 3 is placed in the anode chamber 6 and the cathode chamber 7 respectively, and the anode chamber 6 and the cathode chamber 7 are separated by a cation permeable membrane 5; (2) take 3-chlorophenol solution, add H according to the proton ratio of 1:0.4 2 SO 4 , according to the concentration of 30 ~ 100mmol / L to add Na 2 SO 4 Configure the electrolyte, enter the cathode chamber 7 from the cathode chamber inlet 9, and the liquid before and after electrolysis is separated by the separator 1; (3) get the same Na as the electrolyte 2 SO 4 Concentration of Na 2 SO 4 The solution enters the anode chamber 6 from the anode chamber inlet 10, and the liquid level is adjusted to be close to the cathode chamber 7; (4) the voltage of the power supply 4 is set to 1.5V, and the power supply 4 is...

Embodiment 2

[0039] In the CEH bleaching process, the waste water from the C-section and E-section contained more toxic organic substances, and a variety of chlorophenols and chlorinated guaiacols were detected. Section H contains less toxic organic substances, and no toxic substances such as chlorophenols and chlorinated guaiacols can be detected.

[0040] (1) if figure 1 Shown, will connect the graphite electrode 2 of power source 4 and the C-Pd-Ag / g-C that the present invention method prepares respectively 3 N 4 The composite electrode 3 is placed in the anode chamber 6 and the cathode chamber 7 respectively, and the anode chamber 6 and the cathode chamber 7 are separated by a cation permeable membrane 5; (2) take CEH bleaching wastewater, add H 2 SO 4 , according to the concentration of 30 ~ 100mmol / L to add Na 2 SO 4 Configure the electrolyte, and put into the cathode chamber 7; (3) get the same Na as the electrolyte 2 SO 4 Concentration of Na 2 SO 4 The solution is put int...

Embodiment 3

[0042] Among the AOX detected in ECF bleaching wastewater, chlorophenols and chlorinated hydrocarbons contained the most, and these two types of substances accounted for about 60%. The others were mainly various chlorine-containing acids, furanones, aldehydes and ketones.

[0043] (1) if figure 1 Shown, will connect the graphite electrode 2 of power source 4 and the C-Pd-Ag / g-C that the present invention method prepares respectively 3 N 4 The composite electrode 3 is placed in the anode chamber 6 and the cathode chamber 7 respectively, and the anode chamber 6 and the cathode chamber 7 are separated by a cation permeable membrane 5; (2) take the ECF bleaching wastewater, add H according to the proton ratio of 1:0.4 2 SO 4 , according to the concentration of 30 ~ 100mmol / L to add Na 2 SO 4 Configure the electrolyte, and put into the cathode chamber 7; (3) get the same Na as the electrolyte 2 SO 4 Concentration of Na 2 SO 4 The solution is put into the anode chamber 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com