A kind of macromolecular hydrophobic monomer polytetrahydrofuran diacrylate and preparation method thereof

A technology of polytetrahydrofuran diacrylate and hydrophobic monomer is applied in the field of macromolecular hydrophobic monomer polytetrahydrofuran diacrylate and its preparation, and can solve the problems of weak rigidity, low conversion rate, poor shear resistance and the like, To achieve the effect of enhanced tensile properties, simple preparation method and simple reaction mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

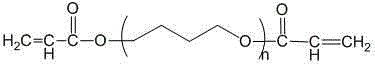

[0022] Polytetrahydrofuran diacrylate, a macromolecular hydrophobic monomer, contains two vinyl structures, and its structural formula is as follows:

[0023] , where n is 13~14.

[0024] The preparation method of above-mentioned a kind of macromolecular hydrophobic monomer polytetrahydrofuran diacrylate specifically comprises the following steps:

[0025] (1) First, add 140.57g of benzoyl chloride and 90.05g of acrylic acid into the flask, then add 0.7g of polymerization inhibitor cuprous chloride, and add 100g of acrylic acid into the constant pressure dropping funnel; secondly, control the pressure to 0.05MPa, temperature Under the conditions of 70°C and a stirring speed of 700r / min, add the acrylic acid in the constant pressure dropping funnel to the beaker at a controlled dropping rate of 6ml / min, and collect the distillate at the same time, that is, acryloyl chloride;

[0026] The amount of benzoyl chloride used above and the total amount of acrylic acid are in a mola...

Embodiment 2

[0036] Polytetrahydrofuran diacrylate, a macromolecular hydrophobic monomer, contains two vinyl structures, and its structural formula is as follows:

[0037] , where n is 13~14.

[0038] The preparation method of above-mentioned a kind of macromolecular hydrophobic monomer polytetrahydrofuran diacrylate specifically comprises the following steps:

[0039] (1), with the step (1) of embodiment 1;

[0040] (2) Add 50g of polytetrahydrofuran, 13.1g of triethylamine and 100ml of chloroform into the reactor, and add 0.1g of polymerization inhibitor hydroquinone, stir in an ice-water bath, and control the dropping rate at 5-6ml / Add 11.7g of acryloyl chloride dropwise at a rate of 1 min, wait until the drop of acryloyl chloride is finished, react for 0.5h, then remove the ice bath, control the temperature at 50°C and continue the reaction for 12h to obtain a reaction solution;

[0041] The amount of polytetrahydrofuran (PTF), triethylamine, methylene dichloride, polymerization inh...

Embodiment 3

[0048] (1), with the step (1) of embodiment 1;

[0049] (2) Add 50g of polytetrahydrofuran, 13g of triethylamine and 100ml of dichloromethane into the reactor, add 0.12g of inhibitor hydroquinone, stir in an ice-water bath, and control the dropping rate at a rate of 6ml / min to 11.3 g of acryloyl chloride was added dropwise, and reacted for 0.5h after the drop of acryloyl chloride was completed, then the ice bath was removed, and the temperature was controlled at 35°C to continue the reaction for 8h to obtain a reaction solution;

[0050] The amount of polytetrahydrofuran (PTF), triethylamine, methylene dichloride, polymerization inhibitor hydroquinone and acryloyl chloride used in the above-mentioned reaction process, press polytetrahydrofuran: acryloyl chloride: triethylamine: dichloromethane: polymerization inhibitor p-phenylene Diphenol is prepared in the ratio of 1000g: 226g: 260g: 2000ml: 2.4g;

[0051] (3), filter the reaction solution obtained in step (2) with a sand c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com