A novel fluorine-containing betaine surfactant and its preparation method and application

A technology of surfactant and betaine, which is applied in the field of fluorine-containing betaine surfactant and its preparation, can solve the problems of environmental pollution, poor activity, high cost, etc., and achieve the effect of high surface activity, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Method for preparing novel fluoro-containing carboxyl betaine surfactants based on octopylol:

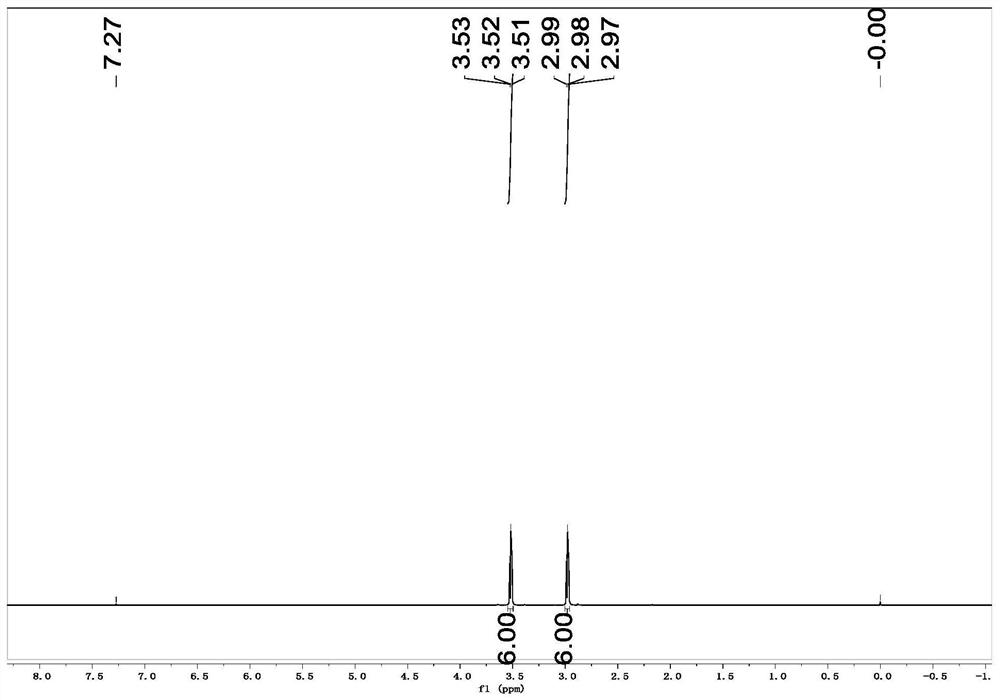

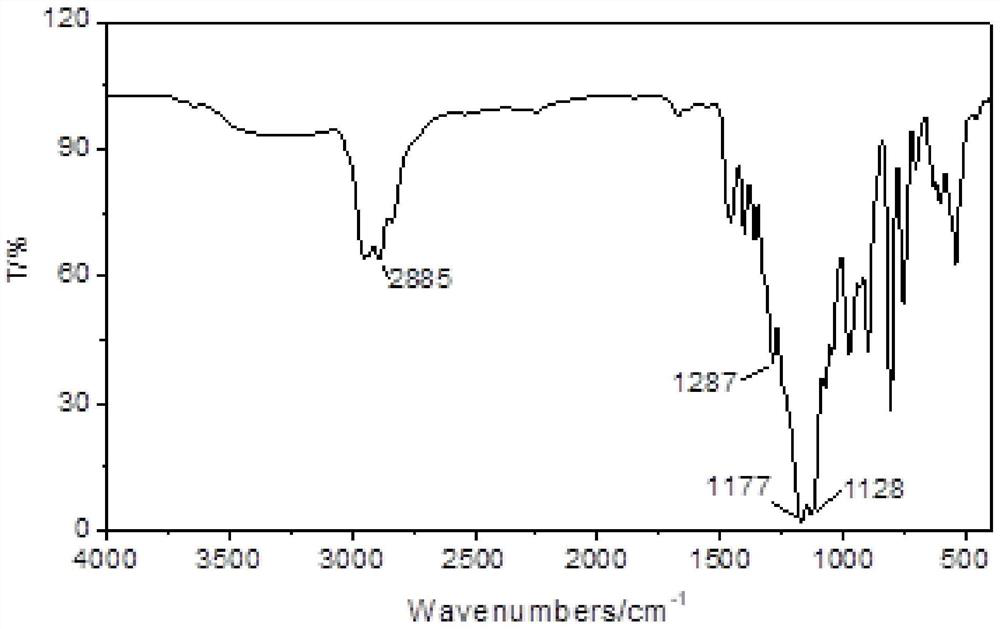

[0035]1) Take 26.5 ml of triethanolamine in 30 ml of DMF, slowly drop 56.65 ml of dichloride when it is low in low temperatures (0 ~ 15 ° C) with a constant pressure drip funnel, and the mixture is increased to 35 ° C for about 1 h. The temperature was warmed to 60 ° C for about 4 h, stopped the reaction, washed the reaction liquid with an aqueous solution of the inorganic base, adjusted the pH of 8 or so, stationary, separation, and the lower oil liquid is three (2-chloroethyl) amine. RMB analysis,figure 1 Indicated.1H NMR (600 MHz, ChlorOform-D) δ3.52 (T, J = 7.0 Hz, 6H), 2.98 (T, J = 7.0 Hz, 6H).

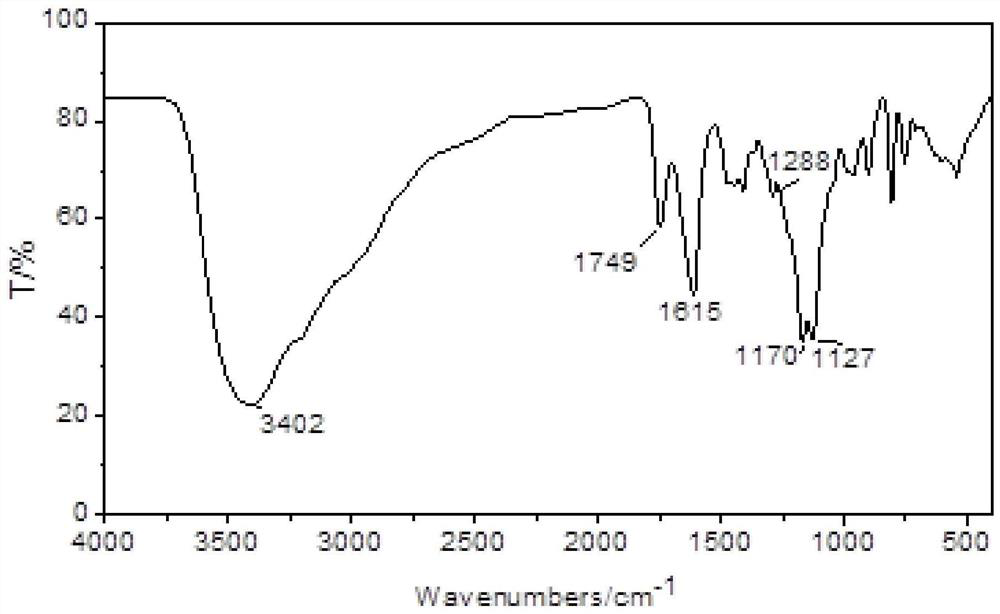

[0036]2) Take 56 ml of octylfluoropentanol and 16 g of sodium hydroxide in a 250 ml three flask in 100 ml of tetrahydrofuran, thoroughly stirred, 15 ml of 15 ml of constant pressure drops, and add it to the three flasks, warmed to After the reaction was 50 ° C, after the reaction was complet...

Embodiment 2

[0041]Preparation method of novel fluorosulfonic acid-containing betaine surfactant based on octopylol:

[0042]1) Take 26.5 ml of triethanolamine in 30 ml of DMF, slowly drop 56.65 ml of dichloride when it is low in low temperatures (0 ~ 15 ° C) with a constant pressure drip funnel, and the mixture is increased to 35 ° C for about 1 h. The temperature was warmed to 60 ° C for about 4 h, stopped the reaction, washed the reaction liquid with an aqueous solution of the inorganic base, adjusted the pH of 8 or so, stationary, separation, and the lower oil liquid is three (2-chloroethyl) amine.

[0043]2) Take 56 ml of octylfluoropentanol and 16 g of sodium hydroxide in a 250 ml three flask having 100 ml of toluene, thoroughly stir, 15 ml of constant pressure drops, 15ml step 1) The resulting product is slowly added to the three flasks, warmed to The reaction was 50 ° C for 5 h. After the reaction was completed, the solid was removed, washed several different effluents with water, and the lowe...

Embodiment 3

[0047]Method for preparing octopyl fluoride sugar base surfactant based on octopylol:

[0048]1) Take 26.5 ml of triethanolamine in 30 ml of DMF, slowly drop 56.65 ml of dichloride when it is low in low temperatures (0 ~ 15 ° C) with a constant pressure drip funnel, and the mixture is increased to 35 ° C for about 1 h. The temperature was warmed to 60 ° C for about 4 h, stopped the reaction, washed the reaction liquid with an aqueous solution of the inorganic base, adjusted the pH of 8 or so, stationary, separation, and the lower oil liquid is three (2-chloroethyl) amine.

[0049]2) Take 56 ml of octylfluoropentanol and 16 g of sodium hydroxide in a 250 ml three flask which is 100 ml of diethyl ether, thoroughly stirring, 15 ml of 15 ml of constant pressure drops can slowly add it to the three flasks, warmed to The reaction was 50 ° C for 5 h. After the reaction was completed, the solid was removed, washed several different effluents with water, and the lower liquid evaporated to evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| critical surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com