CrSiC composite coating for water-based liquid environment as well as preparation method and application of CrSiC composite coating

A composite coating and water-based liquid technology, applied in the coating, metal material coating process, ion implantation plating, etc., to reduce the friction coefficient and wear rate, improve the overall performance and service life, and improve the tribological performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned CrSiC composite coating for a water-based liquid environment, which includes:

[0036] Using multi-arc ion plating technology, using CrSi alloy as target material, protective gas as working gas, C 2 h 2 As the reaction gas, a negative bias voltage is applied to the substrate, a target current is applied to the CrSi alloy target, and a CrSiC composite coating is deposited on the surface of the substrate.

[0037] In some embodiments, the content of Si atoms in the CrSi alloy target is 1-20 at%, preferably, the atomic ratio of Si to Cr is 1-25 at%:1.

[0038] Preferably, the current applied to the CrSi alloy target is 50-70A.

[0039] Preferably, the negative bias voltage applied to the substrate is -50--300V.

[0040] Preferably, the number of the CrSi alloy targets is not limited, and may be greater than or equal to 2 and less than or equal to 8, and the...

Embodiment 1

[0101] In this example, the above-mentioned CrSiC composite coating was prepared on the basis of 316 stainless steel, which is commonly used in water environment, and the preparation method is as follows:

[0102] (1) Pre-plating treatment

[0103] Put the substrate in petroleum ether, and use ultrasonic stirring to clean it for 15 minutes. After removing the oil on the surface of the substrate, put it into acetone and ultrasonically clean it for 15 minutes, then ultrasonically clean it in absolute ethanol for 15 minutes, and finally take it out and dry it with nitrogen;

[0104] (2) Bias reverse sputter cleaning

[0105] Put the substrate treated in step (1) into the multi-arc ion plating chamber, the temperature of the chamber is 350°C, and the back vacuum is pre-evacuated to 4.00×10 -3 Pa; then, pass Ar gas with a purity greater than or equal to 99.999% into the cavity, the Ar gas flow rate is 100 sccm, the substrate is applied with a negative bias voltage, and the substra...

Embodiment 2

[0117] In this embodiment, the substrate is exactly the same as that in Example 1, and a CrSiC composite coating is prepared on the surface of the substrate, and the preparation method is as follows:

[0118] (1) is identical with the step (1) in embodiment 1;

[0119] (2) same as step (2) in embodiment 1;

[0120] (3) same as step (3) in embodiment 1;

[0121] (4) Deposition of CrSiC composite coating

[0122] Taking the CrSi alloy with a purity greater than or equal to 99.5% as the target material, the content of Si in the CrSi alloy target is 10at%, and the others are the same as the step (4) in Example 1;

[0123] (5) Same as step (5) in Example 1, the prepared coating sample is marked as Si10.

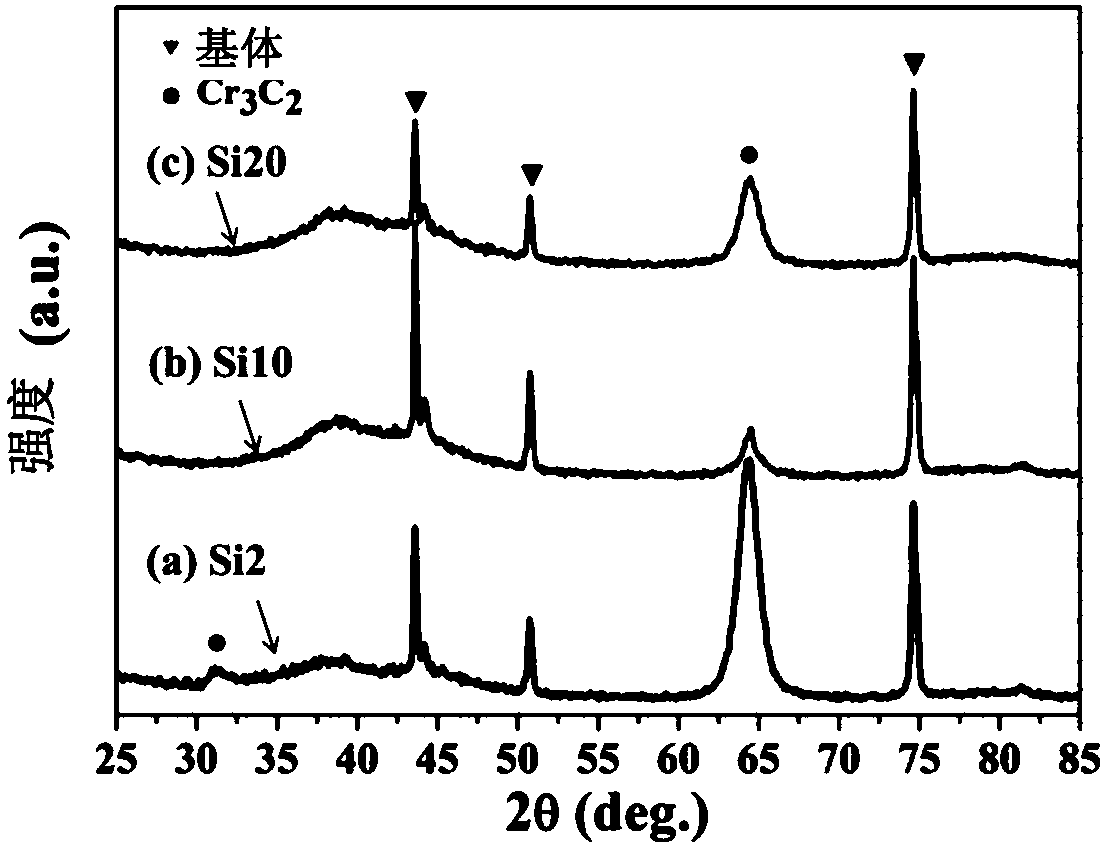

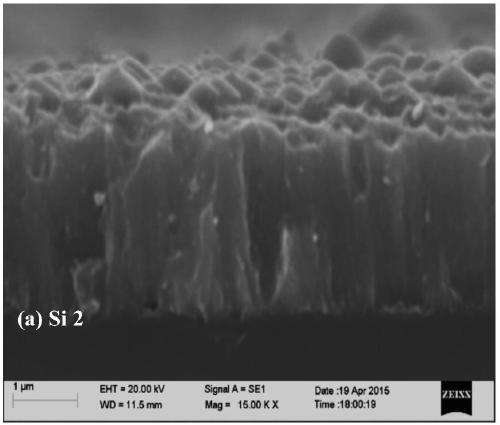

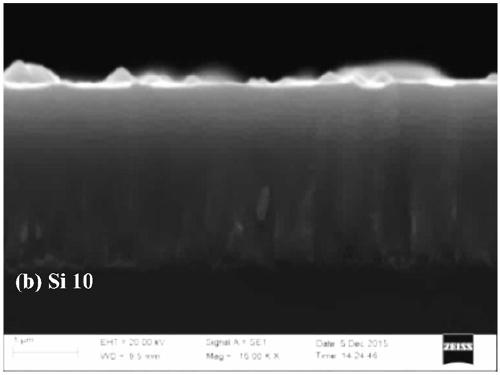

[0124] The composition test results of the CrSiC composite coating prepared in this embodiment are shown in Table 1, and the Si element content in the Si10 coating is 4.3 at%. The XRD test result of present embodiment gained CrSiC composite coating is as follows figure 1 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com