Flip-chip semiconductor device with stress absorption layer made of resin and its manufacture method

A stress-absorbing, semi-conductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

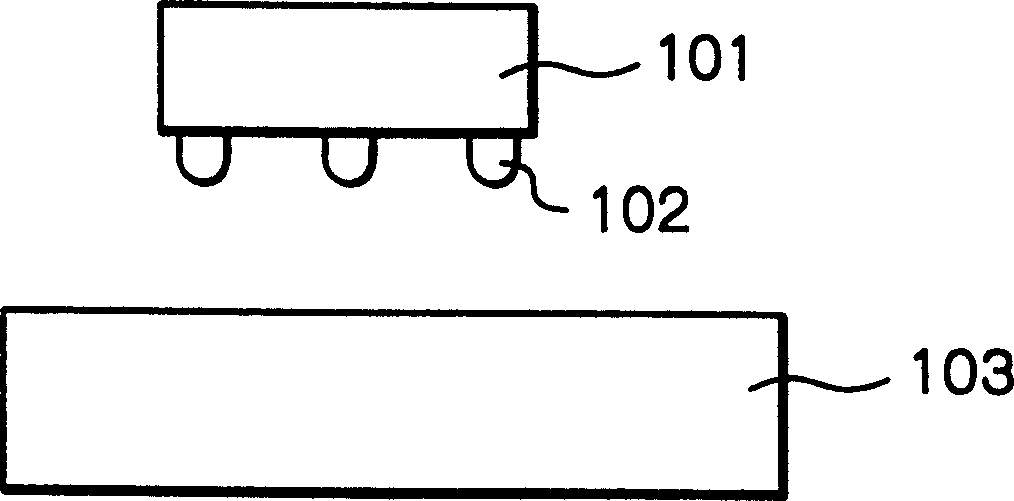

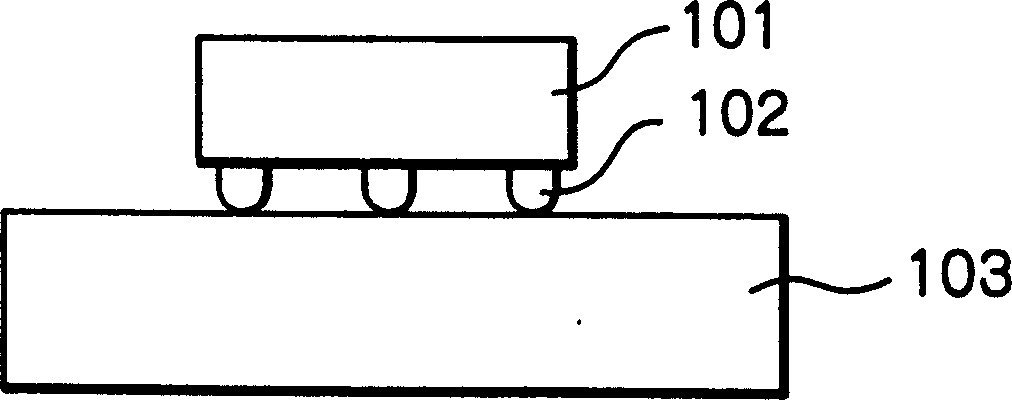

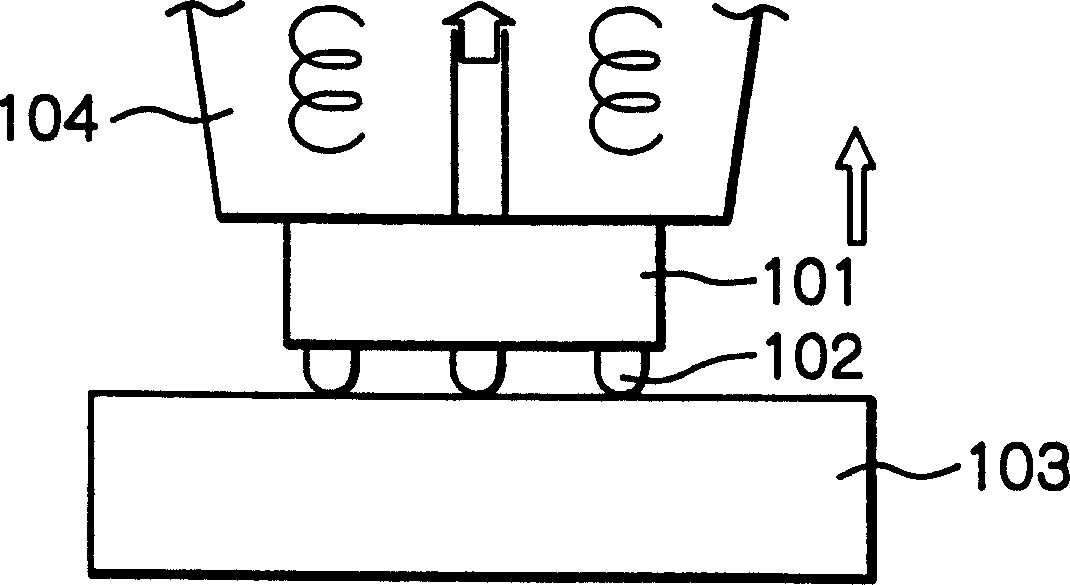

[0035] Before describing the preferred embodiment, reference will be made to Figure 1A , 1B , 1C explains the prior art flip chip type semiconductor device.

[0036] Figure 1A , 1B , 1C are schematic diagrams explaining a conventional method of mounting a flip-chip type semiconductor device on a mother board.

[0037] first reference Figure 1A , a flip-chip type semiconductor device 101 having metal bumps 102 and a motherboard 103 having electrodes (not shown) corresponding to metal bumps 102 are prepared. Note that the motherboard 103 is prepared by the user.

[0038] next step, refer to Figure 1B , the semiconductor device 101 is mounted on the motherboard 103 . Note that if the metal bump 102 is a solder ball, the solder ball is reflowed at one of the predetermined temperatures and soldered on the mother board 103 . In this case, due to the difference in thermal expansion coefficient between the semiconductor device 101 and the motherboard 103 , stress strain is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com