Fluorescent lamp producing method

A manufacturing method and technology for fluorescent lamps, which are applied in the manufacture of discharge tubes/lamps, tube/lamp screens, cold cathodes, etc., can solve the problems of increased process loss, complex manufacturing process, process loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

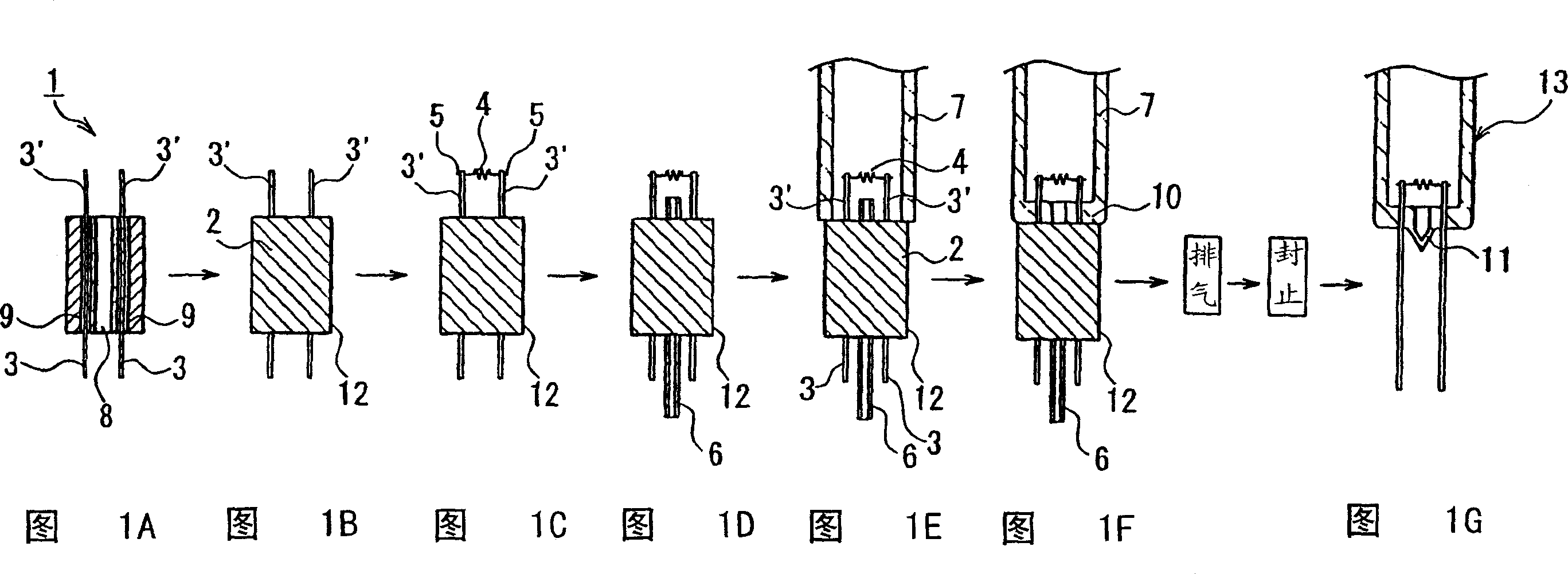

[0038] When connecting two glass tubes with a tube outer diameter of 15.5 mm, a wall thickness of 0.8 mm, and a total length of 180 mm in a bridge type to make a W-shaped compact fluorescent lamp 13 of a discharge circuit, follow the steps of Fig. 1A-Fig. 1G and A fluorescent lamp was produced as described above. The cross-sectional view of the fabricated fluorescent tube is shown in Figure 4 shown.

[0039] Before FIG. 1E , 8 mg of zinc-amalgam as a mercury-releasing alloy and 10 mg of indium-bismuth alloy as an amalgam substance were sealed in the glass tube 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com