Associated wheel arch housing, vehicle, essential portion and manufacturing method

A kind of wheel and shell technology, applied in the direction of vehicle components, superstructure, superstructure sub-assemblies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

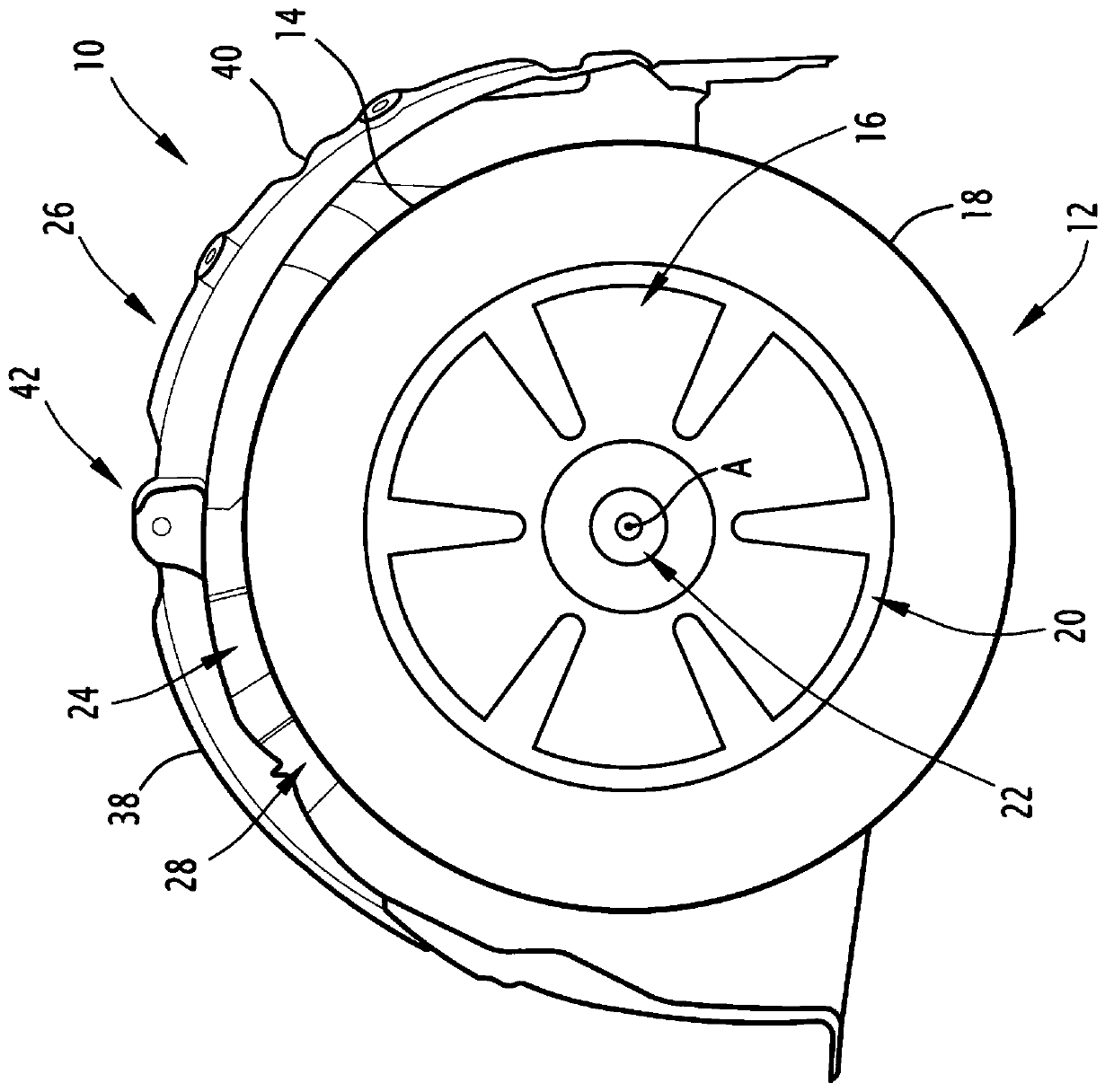

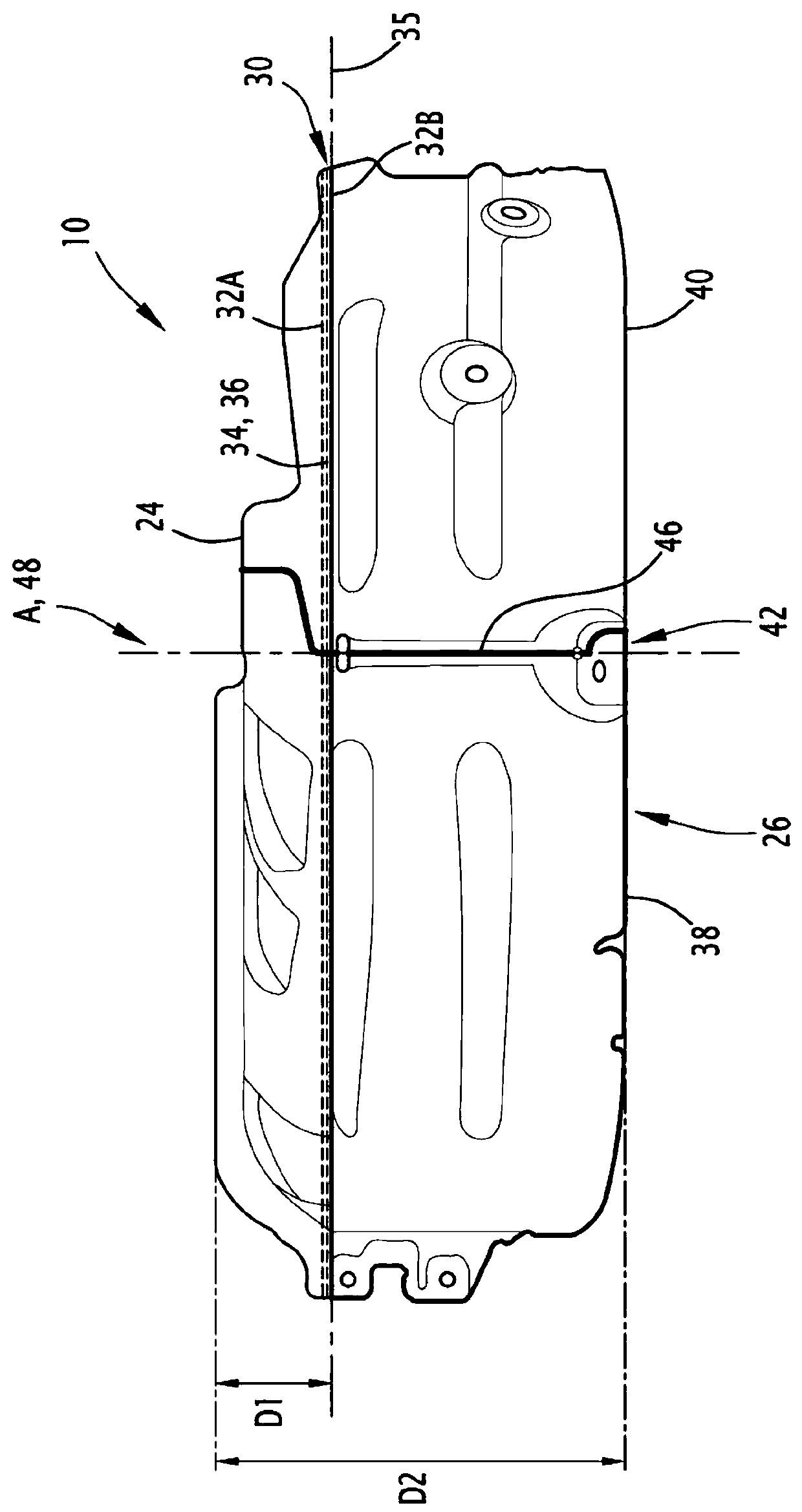

[0032] The motor vehicle according to the present invention includes a wheel arch housing 10 and wheels 12, both of which are shown in figure 1 in.

[0033] Throughout the following text, orientation is the usual orientation of motor vehicles. Therefore, the terms "upper", "lower", "above" and "below" generally extend with respect to a vehicle on an untilted flat bottom.

[0034] The wheel has a tread 14, an inner side surface not shown, and an outer side surface 16.

[0035] The outer side 16 is visible from the outside of the vehicle.

[0036] When the outer side 16 is viewed from the outside of the vehicle, the inner side is hidden by the outer side 16.

[0037] Specifically, the wheel 12 includes a tire 18 and a rim 20 coupled to a hub 22.

[0038] The tread 14 is used to contact the road surface. The tread 14 is formed on the tire 18.

[0039] The wheel 12 is rotatable relative to the hub 22 along the axis of rotation A.

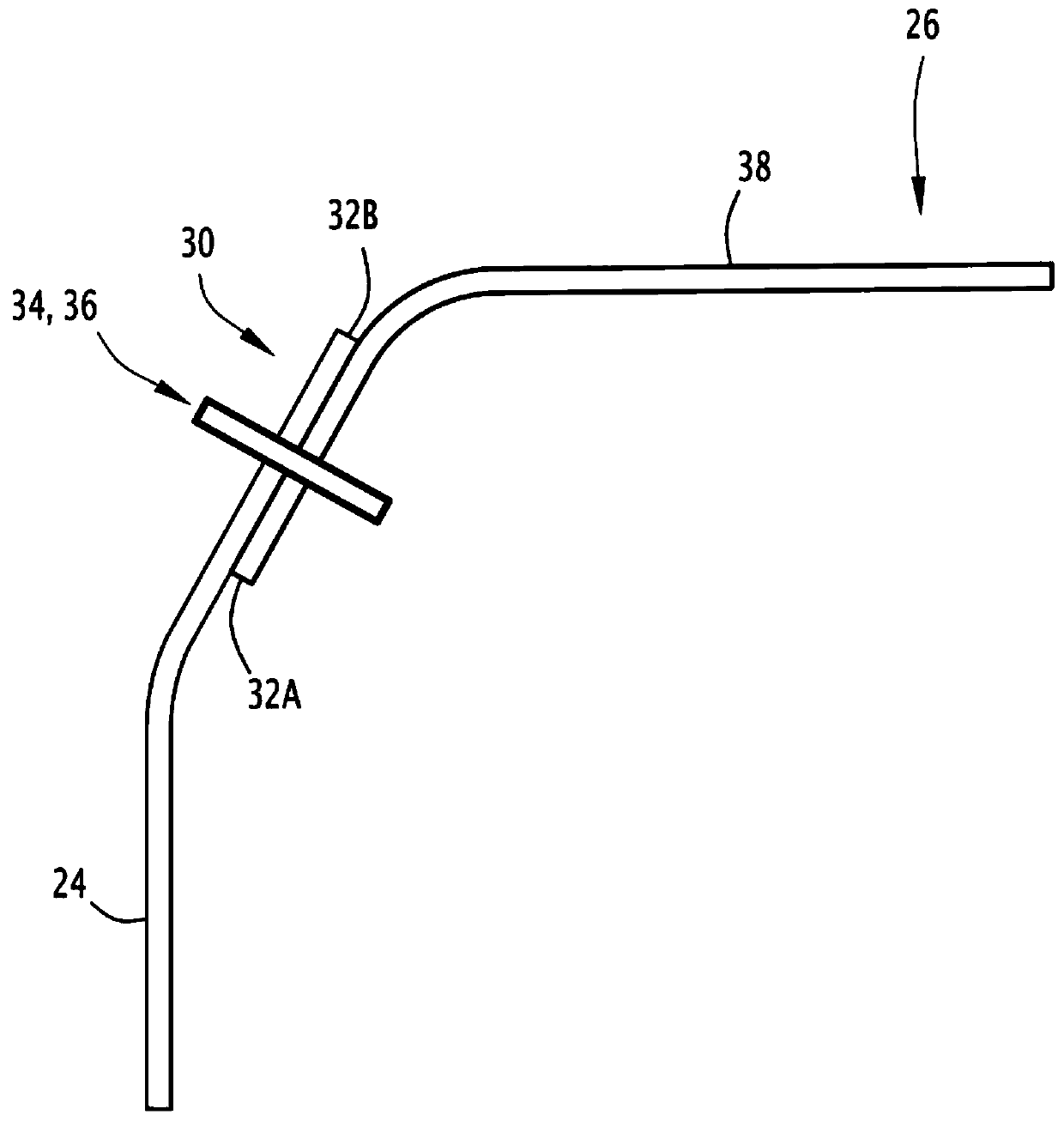

[0040] The dome shell 10 includes an inner deep side wall 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com