Manufacturing method for forming conductor line on non-conductive substrate

A conductor line and manufacturing method technology, applied in the direction of conductive pattern formation, etc., can solve the problems of high requirements for material control and process technology integration capabilities, high technical threshold, etc., and achieve the effect of reducing material demand, improving bonding strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further have a clearer and more detailed understanding of the purpose, technical solutions and advantages of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

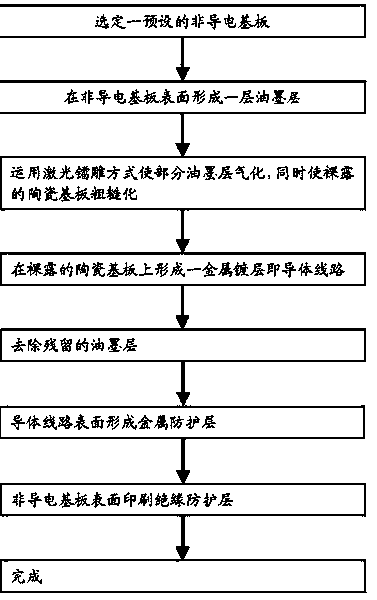

[0024] Please refer to Figure 1 to Figure 7 As shown, the manufacturing method for forming the conductor line 30 on the non-conductive substrate 10 of the present invention includes the following steps:

[0025] a. Select a non-conductive substrate 10, the non-conductive substrate 10 is one of the ceramic materials of alumina, aluminum nitride or silicon carbide, the present invention has no special requirements for the ceramic material of the non-conductive substrate 10.

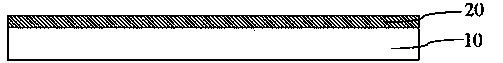

[0026] b. Form an ink layer 20 on the surface of the non-conductive substrate 10 by spraying, screen printing or roller coating. The ink used in the ink layer 20 is smooth insulating paint with certain elasticity.

[0027] c. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com