High strength ultrafine fiber simulation composite lether and its manufacturing method

A technology of superfine fiber and composite leather, applied in textiles and papermaking, etc., can solve the problems of large difference in tensile strength and insufficient high resilience, and achieve the effects of small deformation, good elasticity and reliable manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

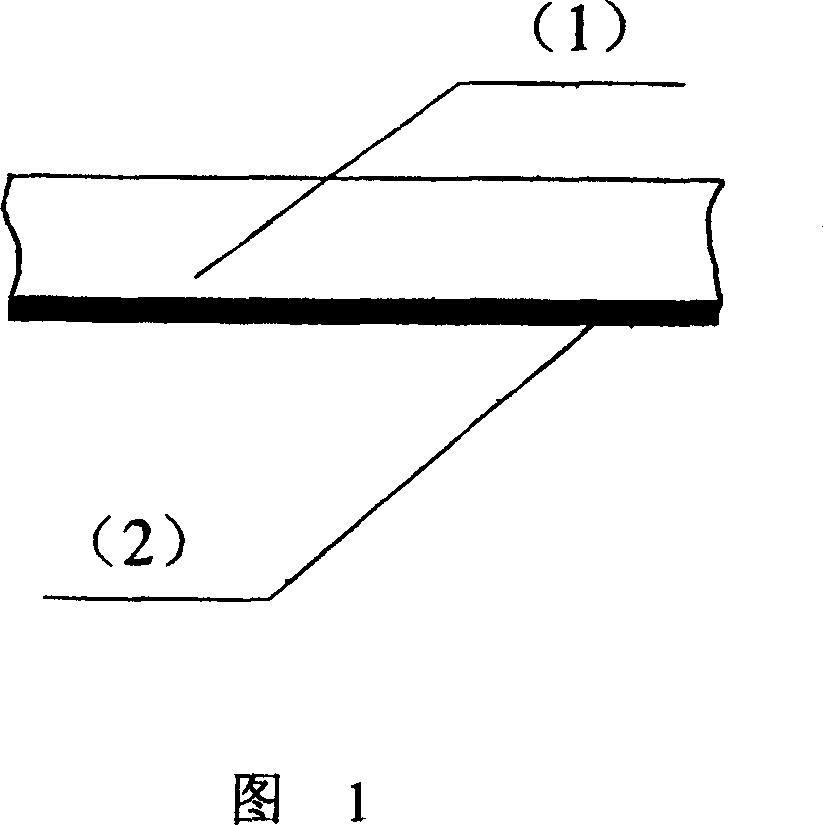

[0034] Nylon-6 and polyethylene are mixed and melted in 70:30 parts by weight, and drawn by a spinning machine to make (3-7)D×(30-65)mm sea-island composite fibers; using textile technology, the The above-mentioned island-in-the-sea composite fiber is made into a woven fabric with a thickness of 0.3mm; the above-mentioned island-in-the-sea composite staple fiber is made into an average grammage of 160g / m by non-woven fabric weaving technology 2 , a non-woven fabric with a thickness of 0.5mm; then the obtained one-layer non-woven fabric and one-layer woven fabric are laminated according to the mode of accompanying drawing 1, and the needle density is 1200 needles / cm 2 Needle-punched under the same conditions to make the base fabric. Vacuum impregnation treatment with 18% polyurethane impregnating solution, passing the impregnating solution at a uniform speed, so that polyurethane is impregnated in the fiber gap, the impregnated amount of polyurethane is 25% of the weight of the...

Embodiment 2

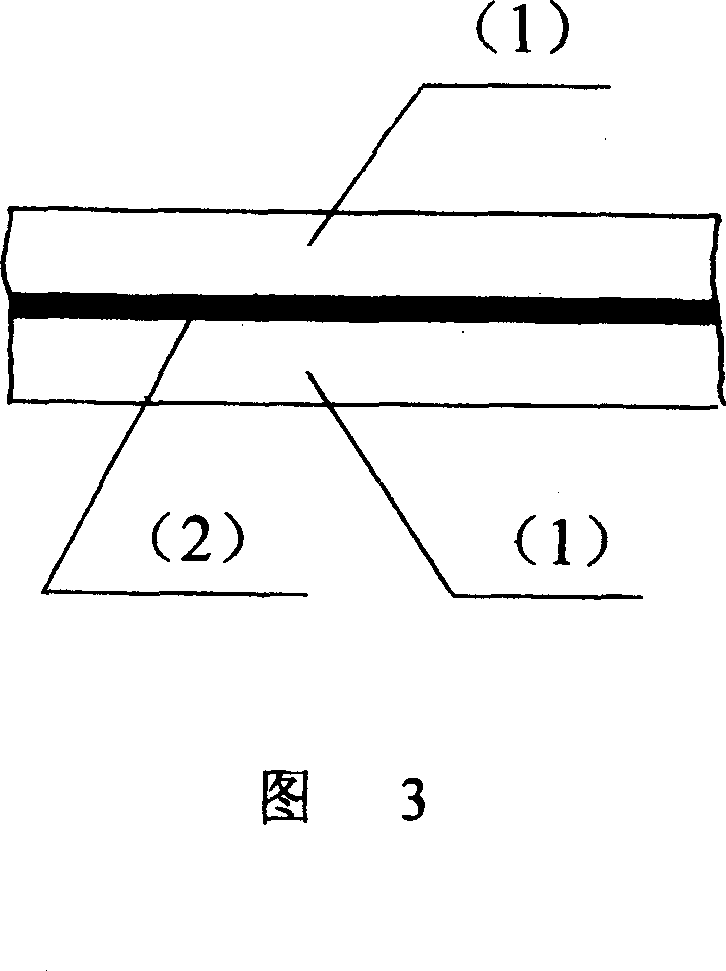

[0037]Nylon-6 and polyethylene are mixed and melted in 65:35 parts by weight, and drawn by a spinning machine to make (3-7)D×(30-65)mm sea-island composite fibers; using weaving technology, the The above-mentioned island-in-the-sea composite fiber is made into a woven fabric with a thickness of 0.5 mm; the above-mentioned island-in-the-sea composite short fiber is made into an average grammage of 300 g / m by using non-woven fabric manufacturing technology 2 , a non-woven fabric with a thickness of 1.0mm; the above-mentioned two-layer non-woven fabric and one-layer woven fabric are laminated according to the method of accompanying drawing 3, and the needle density is 1500 needles / cm 2 Acupuncture compound under the conditions to make the base fabric; use 20% polyurethane impregnating liquid for vacuum impregnation treatment, pass the impregnating liquid at a uniform speed, so that the polyurethane is impregnated in the fiber gap, and the impregnation amount of polyurethane is 35%...

Embodiment 3

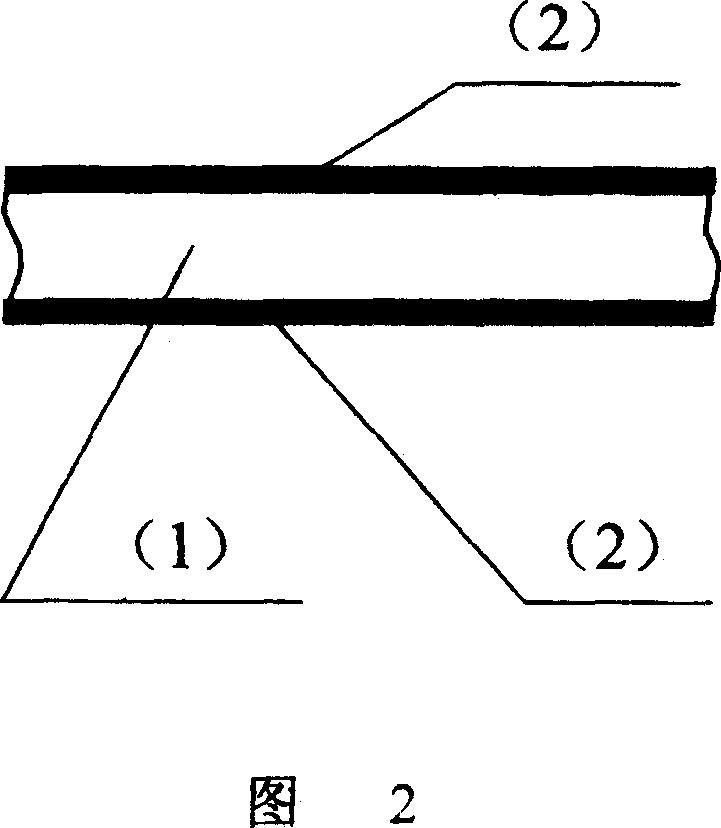

[0040] Polyester and polyvinyl alcohol are mixed and melted in 80:20 parts by weight, and drawn by a spinning machine to make (3-7) D × (30-65) mm sea-island composite fibers; using weaving technology, the The above-mentioned island-in-the-sea composite fiber is made into a woven fabric with a thickness of 0.5 mm; the above-mentioned island-in-the-sea composite short fiber is made into an average grammage of 300 g / m by non-woven fabric weaving technology 2 , a non-woven fabric with a thickness of 1.0mm; the above-mentioned one-layer non-woven fabric and two-layer woven fabric are laminated according to the mode of accompanying drawing 2 and bonded with porous polyurethane to make a composite base cloth; with 25% concentration polyurethane impregnation solution Carry out vacuum impregnation treatment, pass the impregnation solution at a uniform speed, so that the polyurethane is impregnated in the fiber gap, the impregnation amount of polyurethane is 20% of the weight of the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com