Liquid dressing and preparation method thereof

A technology of liquid dressing and liquid matrix, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of accelerating wound healing, and achieve the effect of accelerating wound healing, smooth and smooth film formation, and good disinfection and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

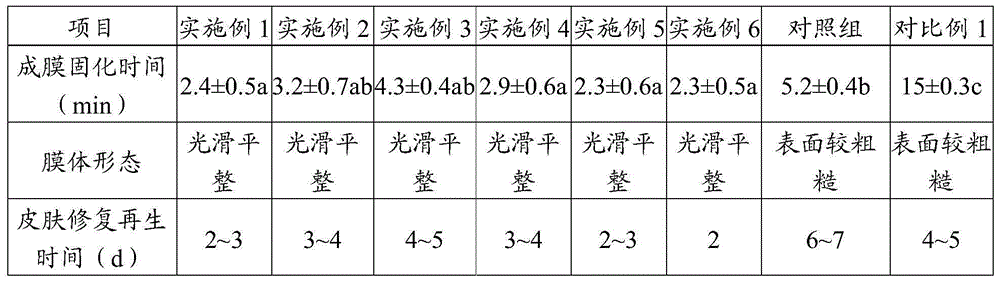

Examples

Embodiment 1

[0050] The preparation of embodiment 1 liquid dressing

[0051] The content of each component in the liquid matrix:

[0052] Polyvinyl alcohol: 9g, gum rosin: 5.5g, absolute ethanol: 75mL,

[0053] Gum turpentine: 15mL, Menthol: 3g, Water: 10mL.

[0054] The content of each component in the powder:

[0055] EGF 30 μg, bFGF 3000 U, hSCGF 55 ng and mannitol 2 μg.

[0056] Wherein, the preparation method of liquid matrix is:

[0057] (1) Heat the purified water to 90°C, keep it warm for 30 minutes, then cool down to 40°C;

[0058] (2) adding polyvinyl alcohol to the warm water obtained in step (1), swelling and dissolving;

[0059] (3) Gum rosin, gum turpentine, and menthol are respectively added in ethanol successively, stirred and dissolved, and set aside;

[0060] Add the mixed solution obtained in step (3) into the polyvinyl alcohol solution in step (2), stir to dissolve, and mix evenly to obtain a liquid matrix.

[0061] The preparation method of powder is:

[0062] ...

Embodiment 2

[0064] The preparation of embodiment 2 liquid dressings

[0065] The content of each component in the liquid matrix:

[0066] Polyvinyl alcohol: 8g, gum rosin: 50g, absolute ethanol: 75mL,

[0067] Gum turpentine: 13mL, Menthol: 2.5g, Water: 12mL.

[0068] The content of each component in the powder:

[0069] hSCGF 55ng and mannitol 3μg.

[0070] Wherein, the preparation method of liquid matrix is:

[0071] (1) Heat the purified water to 90°C, keep it warm for 30 minutes, then cool down to 40°C;

[0072] (2) adding polyvinyl alcohol to the warm water obtained in step (1), swelling and dissolving;

[0073] (3) Gum rosin, gum turpentine, and menthol are respectively added in ethanol successively, stirred and dissolved, and set aside;

[0074] Add the mixed solution obtained in step (3) into the polyvinyl alcohol solution in step (2), stir to dissolve, and mix evenly to obtain a liquid matrix.

[0075] The preparation method of powder is:

[0076] Dissolve hSCGF growth fa...

Embodiment 3

[0078] The preparation of embodiment 3 liquid dressings

[0079] The content of each component in the liquid matrix:

[0080] Polyvinyl alcohol: 5g, gum rosin: 3g, absolute ethanol: 75mL,

[0081] Gum turpentine: 10mL, Menthol: 10g, Water: 15mL.

[0082] The content of each component in the powder:

[0083] EGF 30 μg and mannitol 2 μg.

[0084] Wherein, the preparation method of liquid matrix is:

[0085] (1) Heat the purified water to 90°C, keep it warm for 30 minutes, then cool down to 40°C;

[0086] (2) adding polyvinyl alcohol to the warm water obtained in step (1), swelling and dissolving;

[0087] (3) Gum rosin, gum turpentine, and menthol are respectively added in ethanol successively, stirred and dissolved, and set aside;

[0088] Add the mixed solution obtained in step (3) into the polyvinyl alcohol solution in step (2), stir to dissolve, and mix evenly to obtain a liquid matrix.

[0089] The preparation method of powder is:

[0090] Dissolve the freeze-dried ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap