Pickling-replaced strip steel surface dephosphorization production line

A production line and strip steel technology, applied in workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

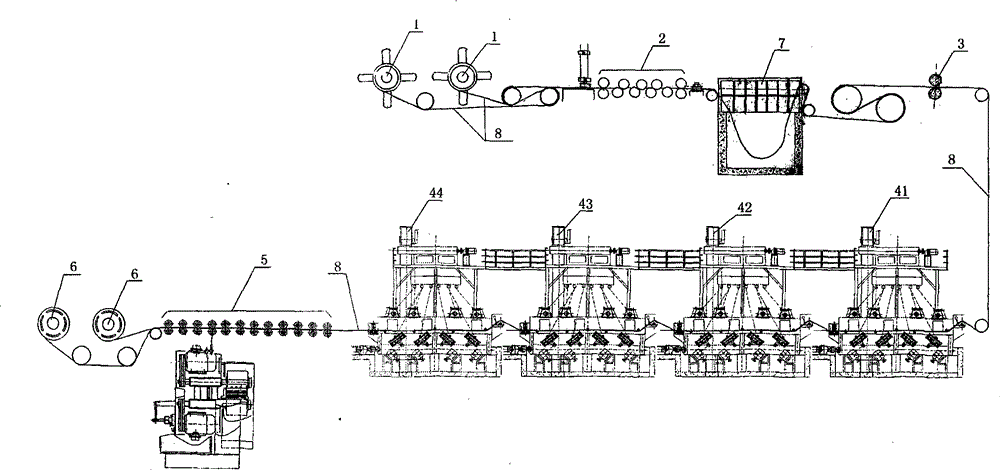

[0013] Such as figure 1 As shown, the replacement production line for dephosphorization on the surface of pickling strip steel includes double-strip uncoiling device 1, leveling device 2, rough oxide layer throwing device 3, shot blasting machine combination device, polishing Wheel combination device 5 and double-strip steel rewinding device 6, storage box 7 is arranged between the above-mentioned leveling device 2 and rough throwing oxide layer device 3, and the shot blasting machine combination device consists of a group from coarse to fine The first-level shot blasting machine 41, the second-level shot blasting machine 42, the third-level shot blasting machine 43 and the fourth-level shot blasting machine 44. The number of the polishing wheels is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com