Short large-aperture inlaid centering fixture

A centering fixture and large-diameter technology, which is applied in clamping, manufacturing tools, positioning devices, etc., can solve the problems that the clamping force of parts is not easy to control, can not realize standardized application, and affect the quality of parts, so as to reduce production preparation The effect of saving time, reducing unit cost of tooling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

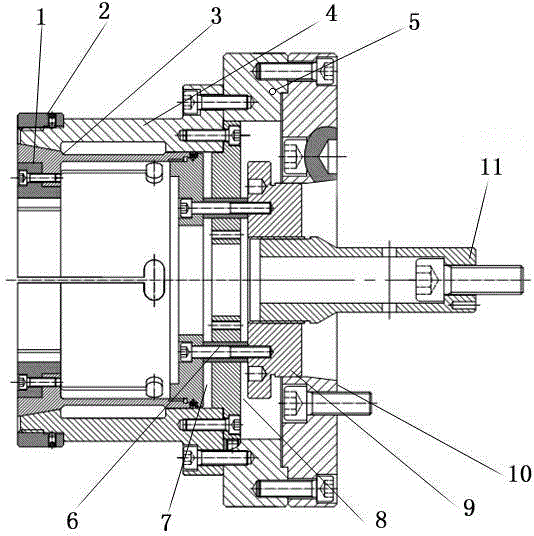

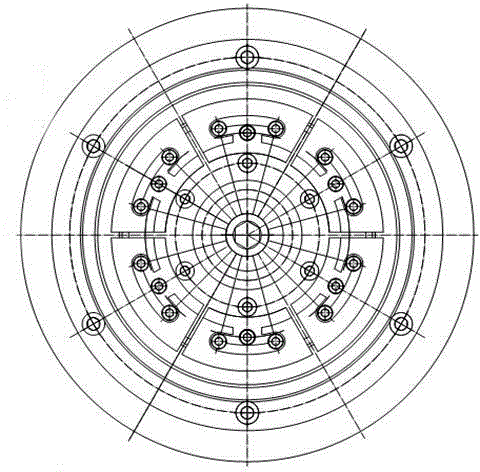

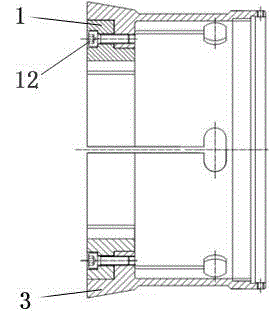

[0027] Such as figure 1 with figure 2 As shown, the present invention includes a flange plate 10 with a guide opening in the center, an annular transition plate 5 is seated on the flange plate 10 and installed by screws, and a clamping body 4 is seated on the transition plate 5 and installed by screws. The guide opening of the flange 10 is provided with a tightening disc 9 with an inner screw hole in the center, and the guide surface of the tightening disc 9 and the guide surface of the flange 10 are in clearance fit. A tie rod 11 is threadedly connected to the central screw hole of the tensioning plate 9, and a connecting plate 8 is installed on the bottom surface of the chuck body 4 by screws, and the connecting plate 8 is located between the spring base 7 and the tensioning plate 9. The lower part of the connecting plate 8 is located in the transition plate 5. A plurality of clamping spring bases 7 and elastic clamping springs 3 are arranged in the clamping body 4, and an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com